COMMODORE 1

32.

To check clutch coil

1.

Disconnect machine power cord from

2.

Disconnect clutch lead connection.

3.

Set

meter to check ohms.

4.

Connect meter leads to clutch leads.

If the meter reads below

160

ohms

or above 195 ohms replace

Accumulation of

dust and

may bause the clutch to

and

lose traction. Remove clutch and

clean

parts

a cleaning

solvent.

outlet.

ASSEMBLY REMOVAL

1.

drive chain (see Photo

28).

2.

Lay machine on side.

3.

Remove nuts and bolts holding

flange bearing to frame.

Remove axle assembly

machine

and put on workbench to service.

5.

Remove snap ring on each end of

axle

to

remove wheels.

WHEEL AND AXLE

1.

Install flange bearing on axle.

Po-

sition set screws (in locking collars)

over innermost flats on axle and

tighten screws.

adjustment

of bearings may be necessary when

assembly to frame.)

2.

When replacing sprocket on axle

note dimension

-

approximately

3

5/16

from end of axle to face of

sprocket. (Photo

33)

35.

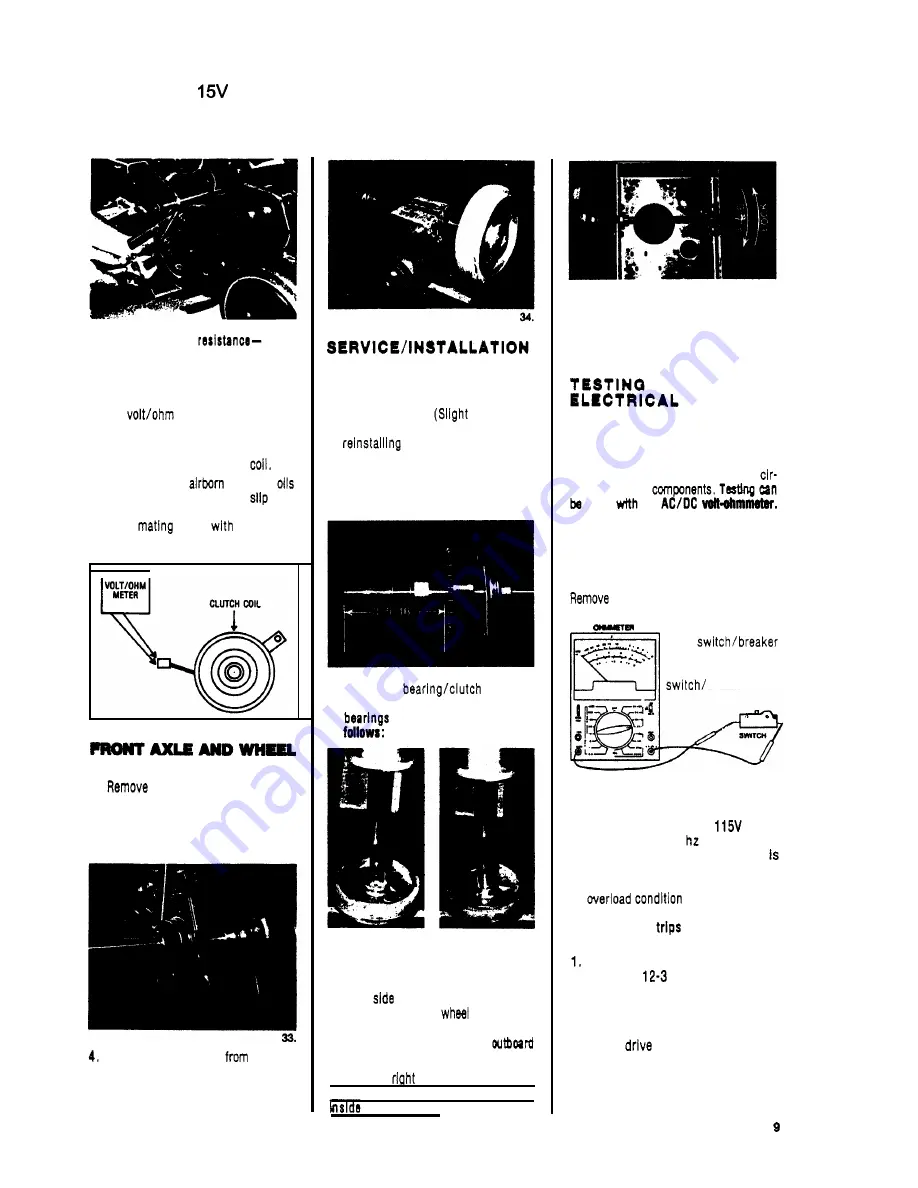

3.

Replacing

bearings

in wheels. Thsss are directional

and must be Installed as

36.

LEFT WHEEL:

Bearing must be

pressed in from

inboard

of

wheel with knurbd

end of bearing

sleeve on Inboard

side of wheel.

37.

RIGHT

WHEEL:

Bearing must be

pressed in from

outboard side of

with knurled

end of bearing

sleeve on

side of wheel.

NOTE:

Both

and left bearing

assem-

blies must be pressed

in

flush with the

of wheel hubs.

38.

4.

To check assembly: hold axle

-

each wheel should rotate forward

freely and lock on shaft when rota-

tion is reversed.

COMMODORE

CIRCUITS:

CAUTION: Repalrs should only be at-

tempted by qualified personnel since

damage can be done by persons not

experienced

in

working with printed

cuit

boards and

done

an

SWITCHES AND

CIRCUIT

BREAKERS

them from machine and use an

ohmmeter or continuity tester. The correct

reading is zero for an

open

and infinity (conti-

nuity) for a closed

brea ker

.

BRUSH DRIVE MOTOR

This motor operates on a

60 hz

circuit

(or

230V

50

depending on

machine model). A

6

amp breaker

Installed

in the drive motor circuit

to

prevent damage to the motor in case

an

occurs.

If the breaker

after being

reset,

check for probable cause:

Incorrect power cord. Use nothing

less than

cable wire size and

no longer than

100

ft

.

2.

Brush height lever set too low. Ad-

just to correct height.

3.

Faulty

motor. Repair or re-

place as required.

4.

Brush assembly “locked-up.” Check

for obstruction

-

faulty brush bear-

ings, etc.

Summary of Contents for COMMODORE CMD

Page 11: ...COMMODORE 115V CONTROL PANEL ASSEMBLY I COMMOOOAE CONTROL PANEL ...

Page 12: ...2 CHASSISWIDRIVE ASSEMBLY ...

Page 14: ...COMMODORE 1 15V 14 ...

Page 16: ...COMMODORE 115V SQtUTION RECOVERY TANKS 16 ...

Page 18: ...COMMODORE 115V CONTROL PANE1 WIRING DIAGRAM 230VOLT CHASSIS WIRING DIAORAM 230 VOLT A I8 i 18 ...