POWER BRUSH ESCORT

(OBS)

3.

Disconnect pump motor

leads.

Disconnect

from pump

head and remove pump. Refer t o

pump drawlng

for

replacement parts.

CAUTION:

When

hose-

barbs on ump head

-

NOT

-

as

could crack

intake and discharge

in

head.

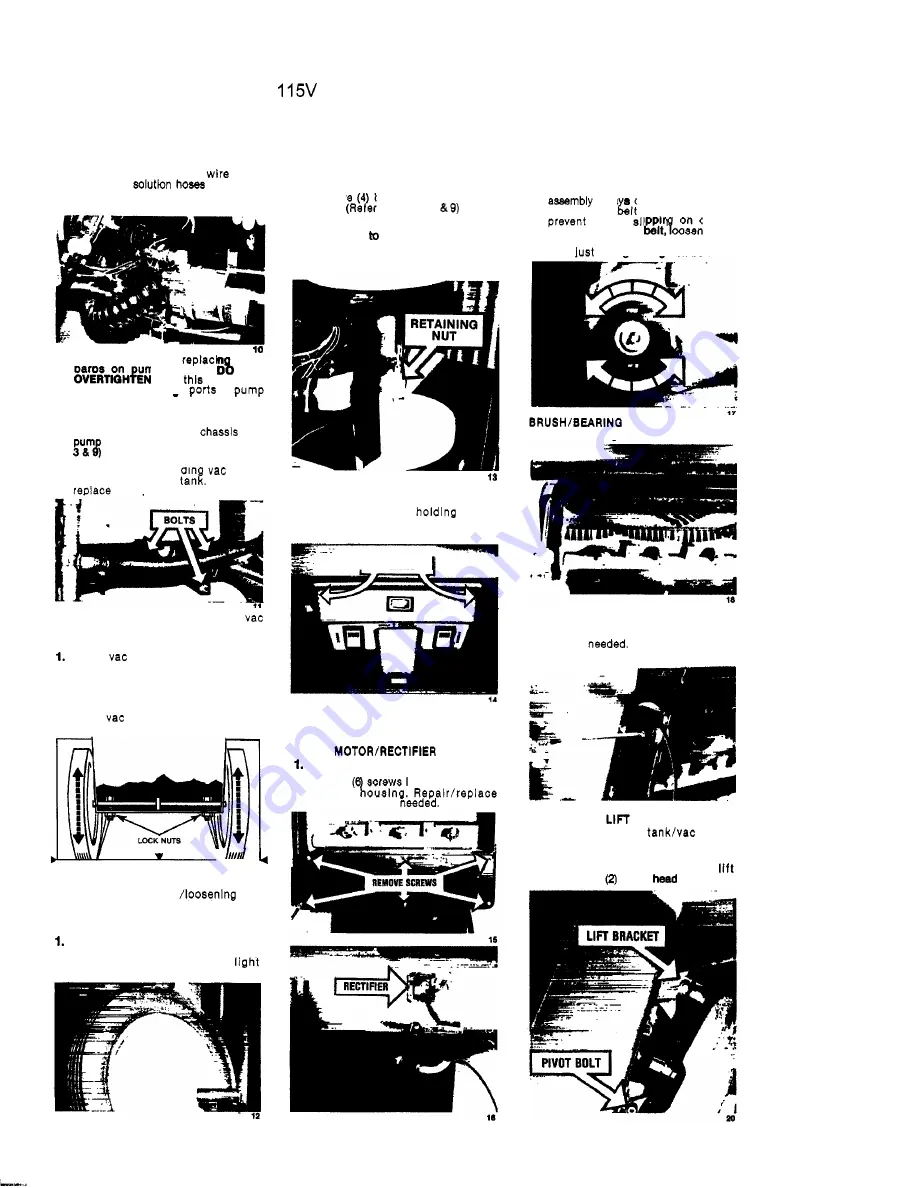

VAC SHOE

1.

Remove

(4)

bolts holding

and

pum plate to tanks. (Refer to Photos

2.

Remove

(3)

bolts hoidin

shoe/

bracket to soiutlon

Repair or

as reaulred.

NOTE

When relnstalllng a new

shoe, proper alignment

of shoe to

floor must be made.

Install

shoe and tlghten screws.

Attach chassis and pump plate as-

sembly to tank and tlghten screws.

2.

Set machine upright on a flat-level

surface (a desk top works well) and

check

shoe for level contact on

the fiat surface.

\

VAC SHOE

LEVEL

WITH

FLOOR

3.

Make adjustment at axle leveling

screws by tlghtenln

both

of the lock nuts unti? shoe Is level.

TRANSPORT WHEELS

Remove screw and hub cap and slide

wheel off axle. Before reinstalling

wheel, clean axle and apply

coating of silicone lubricant.

VAC

MOTOR EXHAUST FILTER

1.

Remove

(4

bolts holding chassis to

tanks.

to Photos

3

2.

Lay machlne on side. Pull chassis

from tanks

expose exhaust muffler.

3.

Remove hex nut from PVC muffler.

Repair or replace as required.

SWITCH CONTROL PANEL

1.

Remove (2) screws

switch

housing to handle. (EPB housing

shown)

I

SCREWS

2.

Replace switches as required.

SERVICING POWER HEAD

BRUSH

Tilt machine back to rest on handle.

2. Remove

screws holding motor and

plate t o

motor rectifier as

Page 4

of 8

BELT ADJUSTMENT

1.

When servicing brush motor

or

brush

alwa check belt

for

proper

tension. The

should

be

taut to

it

from

on cogged

pulleys. To tighten

motor

mounting nuts and rotate motor rear-

ward

enouah to tlahten belt.

ASSEMBLY

1.

Remove belt guard.

2

Remove

screw

from each end of brush

shaft and remove brush assembly

from housing. Replace brush

or bear-

rings as

19

POWER HEAD

CABLE

I.

Remove recovery

motor

assembly.

2. Tilt machlne back to rest on handle.

Remove bolt holding cable t o

bracket and

power

pivot bolts.

4