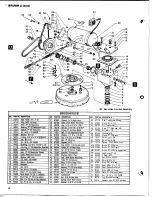

4.

Lift out motor

-

check motor brushes.

worn to

replace brushes.

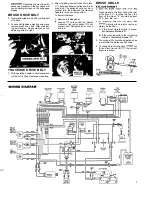

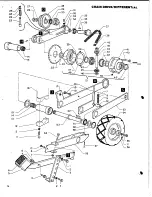

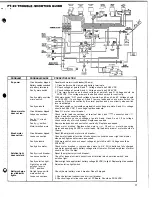

DIFFERENTIAL ASSEMBLY

NOTE:

The differential assembly, traverse

drive motor and brush gear unit can be

removed as a total unit for servicing, if

required.

1.

Lay machine on side or build tripod

supports for each side of machine to

hold unit upright as shown.

3.

Remove axle hub clamps. Lift off assem-

bly and lay on bench to service.

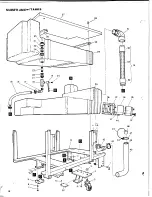

AXLE ASSEMBLY

1.

Remove bolt holding wheel to axle.

2.

Remove wheel from axle. Use wheel

puller, if needed, being careful not to

damage threads in center hole of axle.

3.

To

remove axle and bearings from hub

...

A.

Remove snap ring from hub.

B.

Use an arbor press or hammer and

block of wood to remove bearing and

axle.

2.

Remove boits from brush lift arm bracket

and traverse drive connecting arm.

C.

To remove roiler bearing from hub,

use a piece of

dia. tube to drive

out bearing.

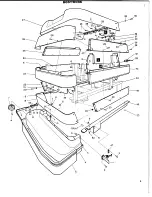

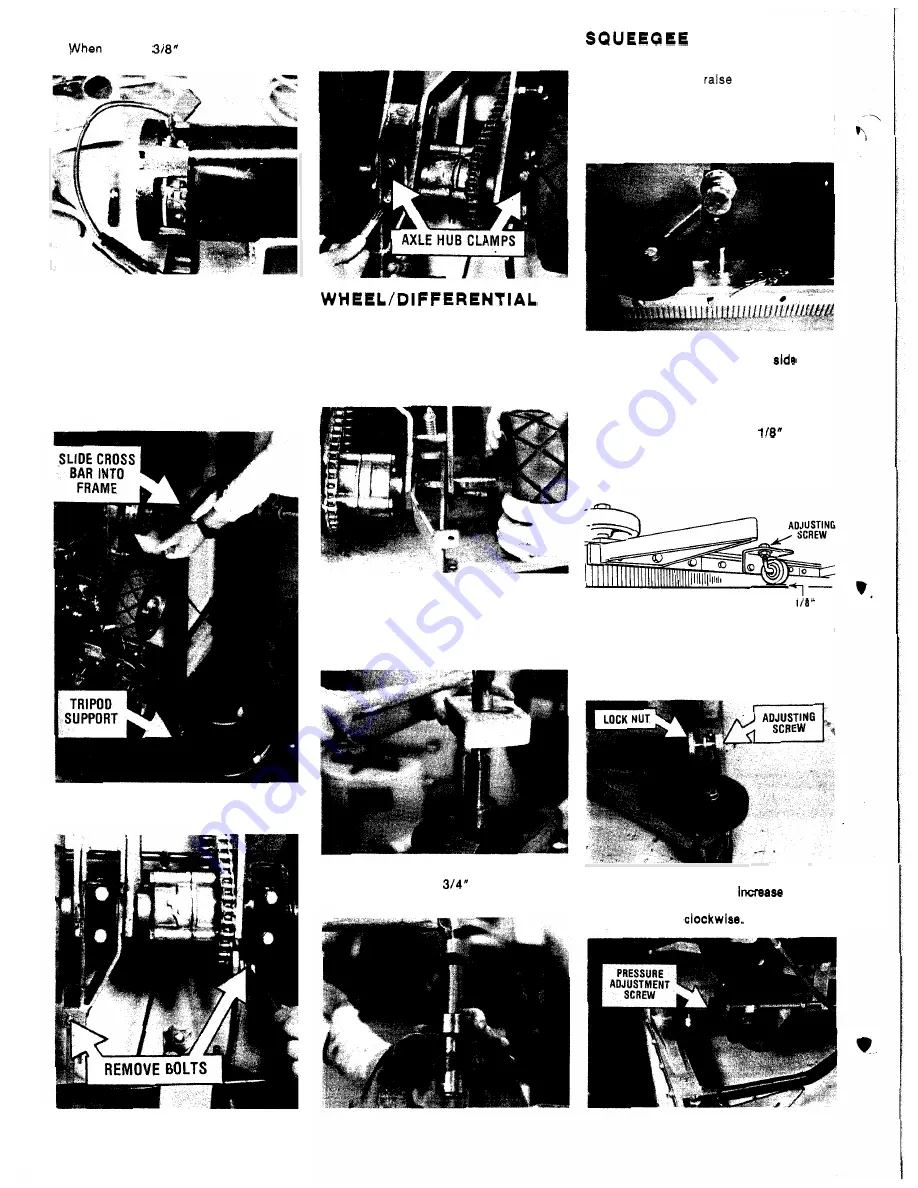

ASSEMBLY

To

remove squeegee assembly..

.

1.

Depress pedal to

squeegee.

2.

Pull retaining pin from locator stud.

3.

Push down on squeegee to remove from

drag arm and slide squeegee to the right

to disengage right hand stud from arm.

4.

When installing or replacing squeegee

blades make sure the smooth

of the

blade is next to the squeegee casting.

5.

Squeegee support caster

-

with

squeegee assembly setting perpendicular

to the floor surface, adjust caster to a

clearance of approximately

between

bottom of caster and the floor.

As

the

squeegee blades wear, adjust caster to

maintain this dimension.

6. The angle of the squeegee c a n be

changed with the adjusting screw. Turn

screw clockwise to tilt squeegee forward

and counterclockwise to tilt rearward.

Tighten lock nut after making adjustment.

7.

Squeegee pressure can be changed with

the adjusting screw.

To

pressure

turn counterclockwise, t o decrease

pressure turn

6

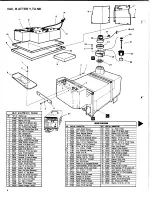

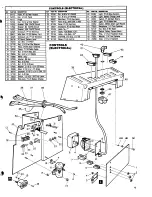

Summary of Contents for PowerTec20

Page 1: ......

Page 9: ...1 7 AI 1 6 9...

Page 10: ...MAINFRAMEWITANKS 38 I 34 37 36 35 39 41 i o 1 3 14 1 46...

Page 11: ...SQUEEGEE w ARM 59 69 21 1 I __ 11...

Page 13: ...48 4 9 50...

Page 14: ...14 2 1 IAL 39...