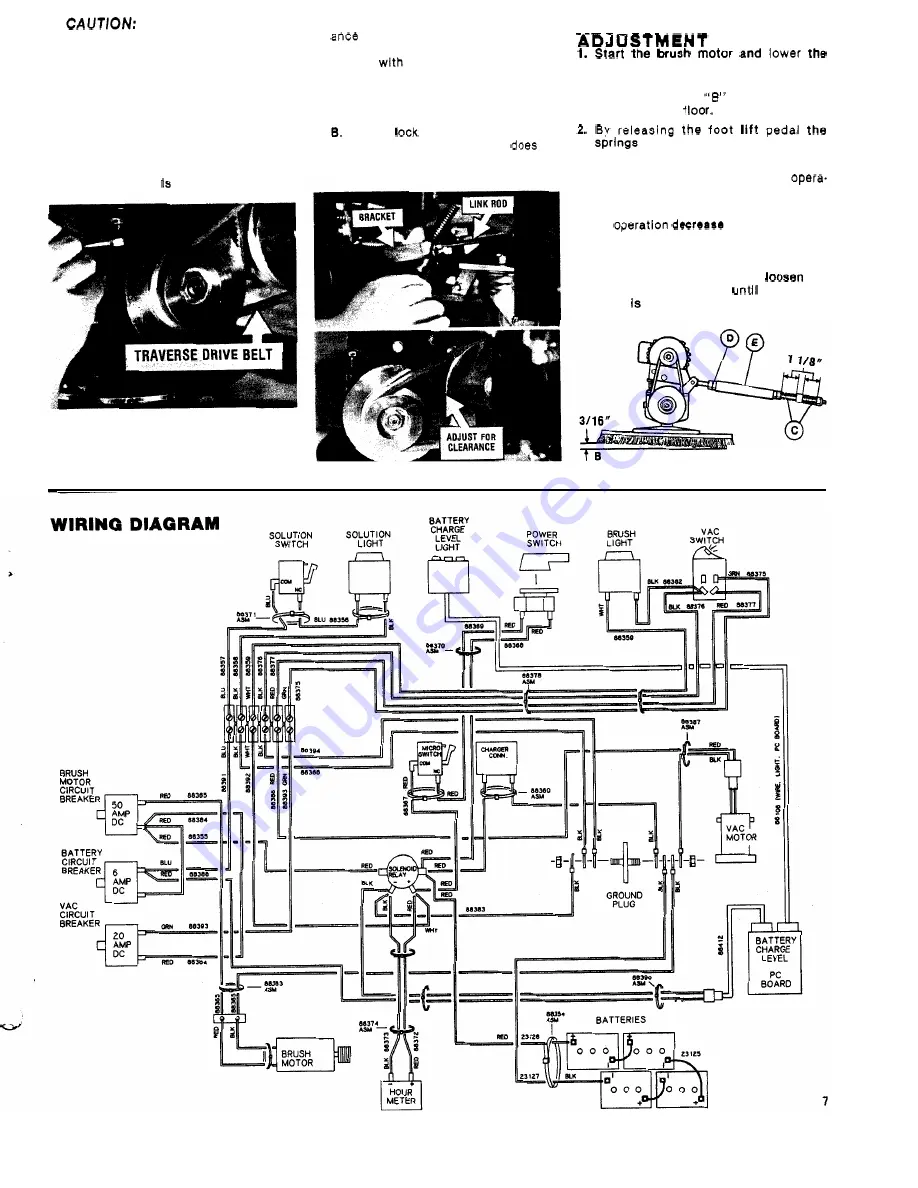

2.

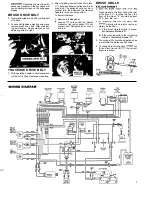

After installing new belt check for clear-

between traverse pulley and brush

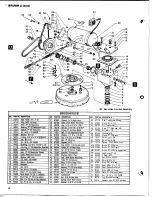

BRUSH ANGLE

Operating the machine with

excessive pressure on the squeegee will

cause abnormal wear on the squeegee

blades.

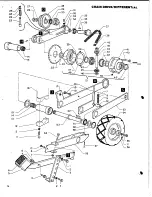

BRUSH DRIVE BELT

1.

Remove traverse drive belt by rolling belt

off pulley.

2.

Loosen belt tension adjusting screw and

remove brush drive belt. After readjust-

ing belt tension, make sure lock nut on

adjusting screw

tight.

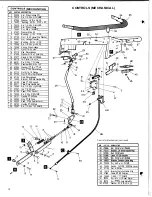

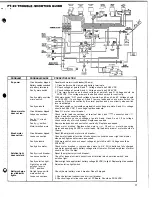

TRAVERSE DRIVE BELT

1.

With operating handle in neutral position,

roll belt off pulley. Replace as required.

drive belt. The pulley should not be in

contact

the belt when the traverse

handle is in the neutral position.

brush slowly to the floor. When the rear

of the brush “A” touches the floor, the

To adjust clearance:

A.

Remove left side panel.

front of the brush

should be about

3/16”

from the

Loosen

nuts on link rod. Adjust

bracket on link rod

so

pulley

not

will allow the brush to rest com-

contact belt. Retighten lock nuts on

pletely on the floor.

link rod.

A.

If

the brush vibrates while in

tlon

Increase dirtanu

“B”.

B.

If the machine pulls to the left during

dlrtanu

“B”.

3.

The springs

(C)

should be adjusted

so

as

to maintain the distances

as

shown.

4. To

change brush inclination,

nut

(D)

and turn tie-rod

(E)

the correct

angle

reached.

A

Summary of Contents for PowerTec20

Page 1: ......

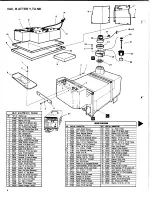

Page 9: ...1 7 AI 1 6 9...

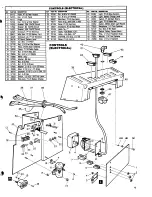

Page 10: ...MAINFRAMEWITANKS 38 I 34 37 36 35 39 41 i o 1 3 14 1 46...

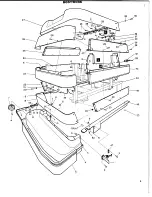

Page 11: ...SQUEEGEE w ARM 59 69 21 1 I __ 11...

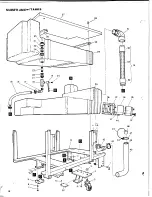

Page 13: ...48 4 9 50...

Page 14: ...14 2 1 IAL 39...