OPERATION (Continued) & TROUBLESHOOTING

98330 03/28/00

5

6. Turn on the power switch on the side of the

extractor. Squeeze the solution lever on the

cleaning tool to spray cleaning solution and

place the vacuum head on the surface to be

cleaned.

IMPORTANT!

ALWAYS TEST UPHOLSTERY

FOR COLOR FASTNESS IN AN INCONSPICUOUS

PLACE. Also, to avoid prolonged drying times, do

not spray too much solution in any one area.

7. When cleaning, be sure to monitor the level of

recovered solution in the recovery tank. When

the solution reaches the FULL mark, shut off the

extractor, loosen the latches and empty the

recovery tank.

WARNING!

DO NOT operate the extractor if the

solution level is above the FULL mark on the

recovery tank; water could be drawn directly into the

vac motor and this will damage the motor.

NOTE: The solution pump is not intended to run

dry. When using this extractor for vacuum pick-

up only, insure that the pump switch is turned

off.

B. WHEN FINISHED OPERATING

WARNING!! Before making any adjustments or

performing maintenance, disconnect the power

cord from the electrical source.

1.

Empty recovery tank completely and rinse it

several times to remove any dirt or debris that

may be left behind.

TROUBLESHOOTING

2.

Tip the solution tank to the rear over a sink to

drain any unused cleaning solution and rinse

with clean water to remove any suds left by the

cleaning chemicals.

3.

Check the spray jet on the cleaning tool for full

spray pattern and inspect vac head for any

obstructions.

C. PERIODIC MAINTENANCE

1.

Twice a month, flush a white vinegar solution

(One quart vinegar to two gallons water) or anti-

browning solution (mixed as directed) through

the extractor. This will prevent build-up of

alkaline residue in the system.

2.

If spray jet becomes clogged, remove the spray

tip, wash it thoroughly, and blow dry.

IMPORTANT! Do not use pins, wire, etc. to clean

nozzle as this could destroy the spray pattern.

3.

Apply silicone lubricant to solution nipple.

4.

Periodically inspect all hoses, electrical cable

and connections on your machine. Frayed or

cracked hoses should be repaired or replaced to

eliminate vacuum or solution pressure loss. If

the cable insulation on the power cord is broken

or frayed, repair or replace it immediately. Don’t

take chances with electrical fire or shock.

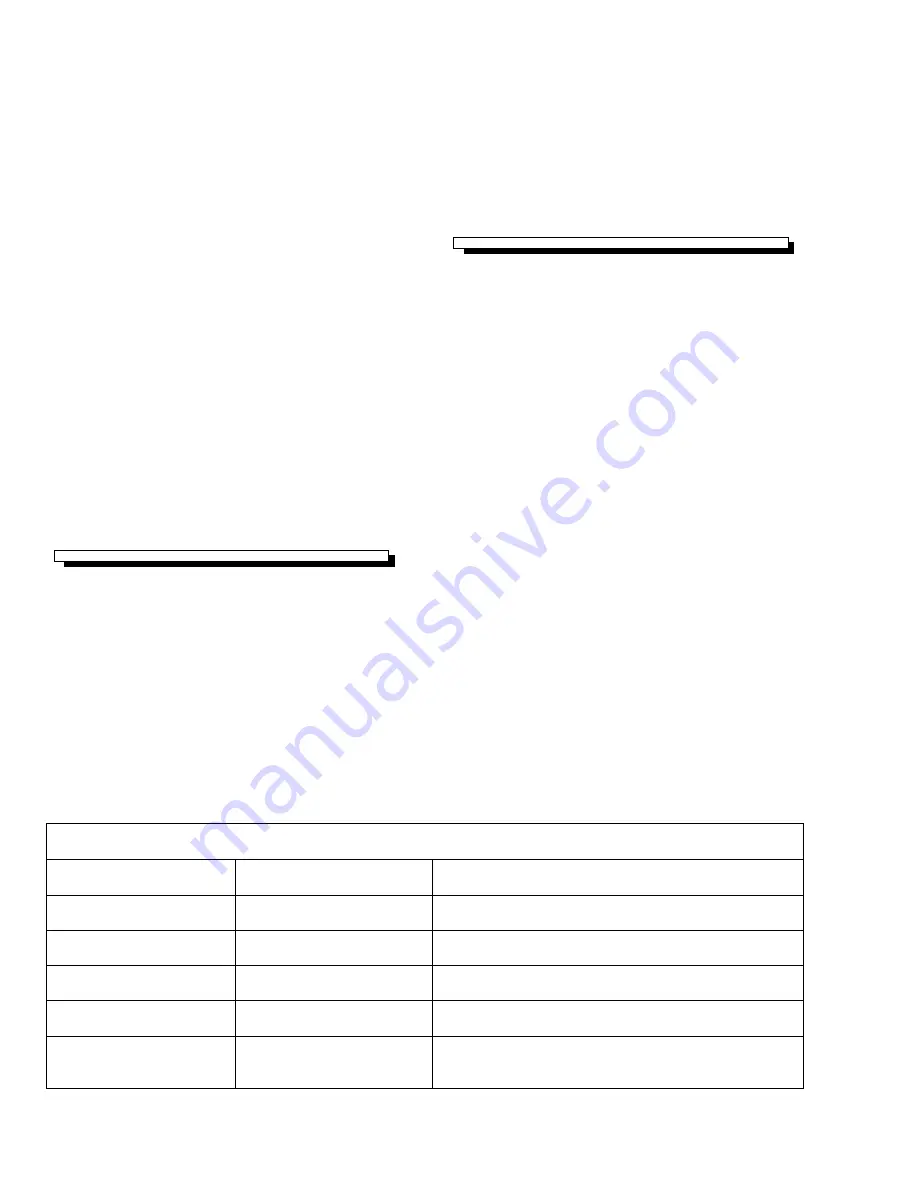

PROBLEM

.

CAUSE

SOLUTION

Little or no solution

flow

Clogged spray jet on

cleaning tool

Remove and clean jets

Faulty pump

Check and replace pump.

(Call Windsor Tech. Services first)

Incorrectly attached

solution hose

Ensure solution hose coupler is securely attached to

the coupler on the solution tank.

Loss of vacuum/

Solution recovery

Incorrectly attached vac

hose

Ensure vac hose is pushed completely onto the

recovery tank inlet.

Obstruction in cleaning

tool

Inspect for and remove any debris.

Recovery tank is not

securely mounted on the

solution tank.

Tighten latches on either end of the machine.