TRANSPORTING MACHINE

QUICK 98560 09/20/99

3-11

TOWING OR PUSHING MACHINE

The

QUICK©

may be towed for short distances at

speeds not to exceed 5 mph. Be careful to avoid

damaging machine. Attach towing device at tie

down point. The machine may be pushed by hand

from the rear.

NOTE: To avoid damage caused by regenerative

voltage, unplug traction motor before towing or

pushing machine.

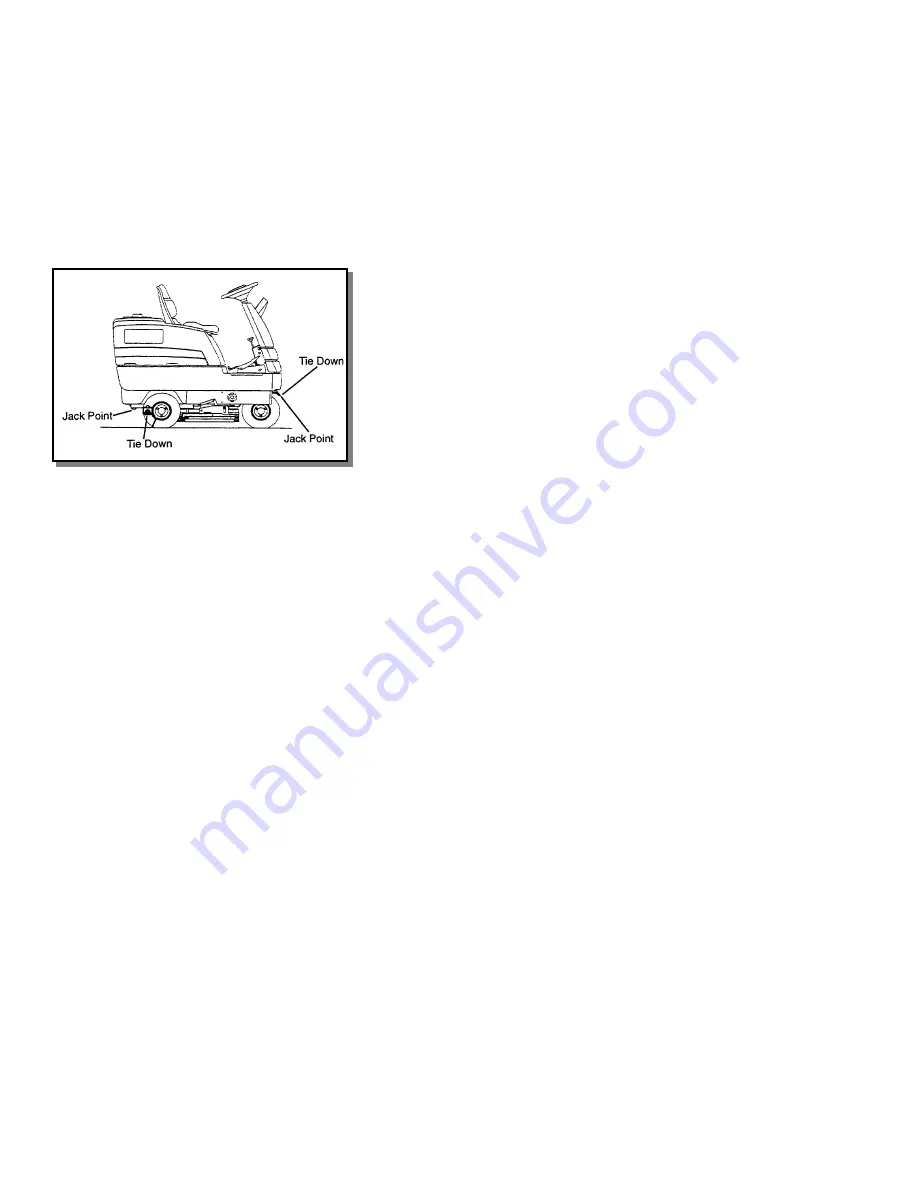

MACHINE TIE-DOWNS

There are two tie points located at the rear, side of

the machine frame and one on the steering fork

above front tires. Tie-down devices must be of the

proper type and strength. The combined strength of

all tie-downs must be strong enough to lift tow times

the weight of the machine. Tie-downs must be

positioned to prevent the machine from moving

forward, backward, or either side to side. Use all

four corners of the machine with the tie-downs

running out opposite directions. Tie-downs must be

attached to the transporting vehicle securely.

PREPARATION FOR TRANSPORTING

Remove squeegee tool to eliminate interference with

tie-downs.

Scrub head must be in the up position before

loading.

NOTE: When transporting the machine on a trailer or

in a truck, in addition to using tie-downs, be sure to

set the parking brake, and block the tires to prevent

the machine from rolling.

MACHINE JACKING

The machine may be jacked up for service or

inspection by using the specified jack locations.

Always block the tires when jacking up the machine.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

The rear jack points are the frame just behind the

rear wheels. Remove the squeegee tool before

jacking.

NOTE: See Squeegee Tool Removal in

Maintenance Section.

The front jacking point is the steering fork just above

the front tires.