MAINTENANCE

SABER (SC) 86038350 01/29/07

4-6

SQUEEGEE BLADES

The front squeegee blade allows solution to pass

through channels in the blade into the squeegee

assembly while maintaining vacuum to provide lift.

The rear blade wipes the floor to a near dry

condition. It is important the rear blade be in good

condition to properly do its job.

Check both the front and rear squeegee blades for

damage and wear each day in the pre-run check.

Change the front blade if it is torn or has an uneven

edge. Change the rear blade if it is less than 1/2 the

original thickness.

TO REMOVE SQUEEGEE ASSEMBLY

1.

With the squeegee in the up position, turn the

machine power off.

2.

Loosen both squeegee knobs and pull squeegee

assembly rearward from the lifting carrier.

3.

Inspect or repair as necessary and reinstall.

TO REPLACE SQUEEGEE BLADES

1.

With the squeegee in the up position, turn the

machine power off.

FOR SAFETY: Before leaving or servicing

machine; stop on level surface, turn off machine

and remove key.

2.

Remove the squeegee assembly from the

machine. Remove all screws and remove blade

retainer strap and remove squeegee blade.

3.

Replace squeegee blades as required.

4.

Install blade with ribbed surface facing out.

5.

Install squeegee retainer strap.

6.

Install all screws starting from center and

working to ends.

DELUXE SQUEEGEE BLADES

The front squeegee blade allows solution to pass

through channels in the blade into the squeegee

assembly while maintaining vacuum to provide lift.

The front blade has four wear surfaces and can be

rotated for extended life. The front blade should not

require regular replacement under normal use.

The rear blade wipes the floor to a near dry

condition. It is important the rear blade be in good

condition to properly do its job. Each rear squeegee

blade has four wear surfaces for extended service.

Check both the front and rear squeegee blades for

damage, wear, and adjustment each day in the pre-

run check. Change the front blade if it is torn or has

an uneven edge. Change the rear blade if it is less

than 1/2 the original thickness.

ADJUSTING DELUXE SQUEEGEE

Adjusting the squeegee is a two-part process. First,

the squeegee assembly must have correct pitch in

order for the squeegee blade to have the same

deflection at each tip as well as the center. The

knob on the squeegee linkage controls the pitch

adjustment. The second adjustment is the

deflection.

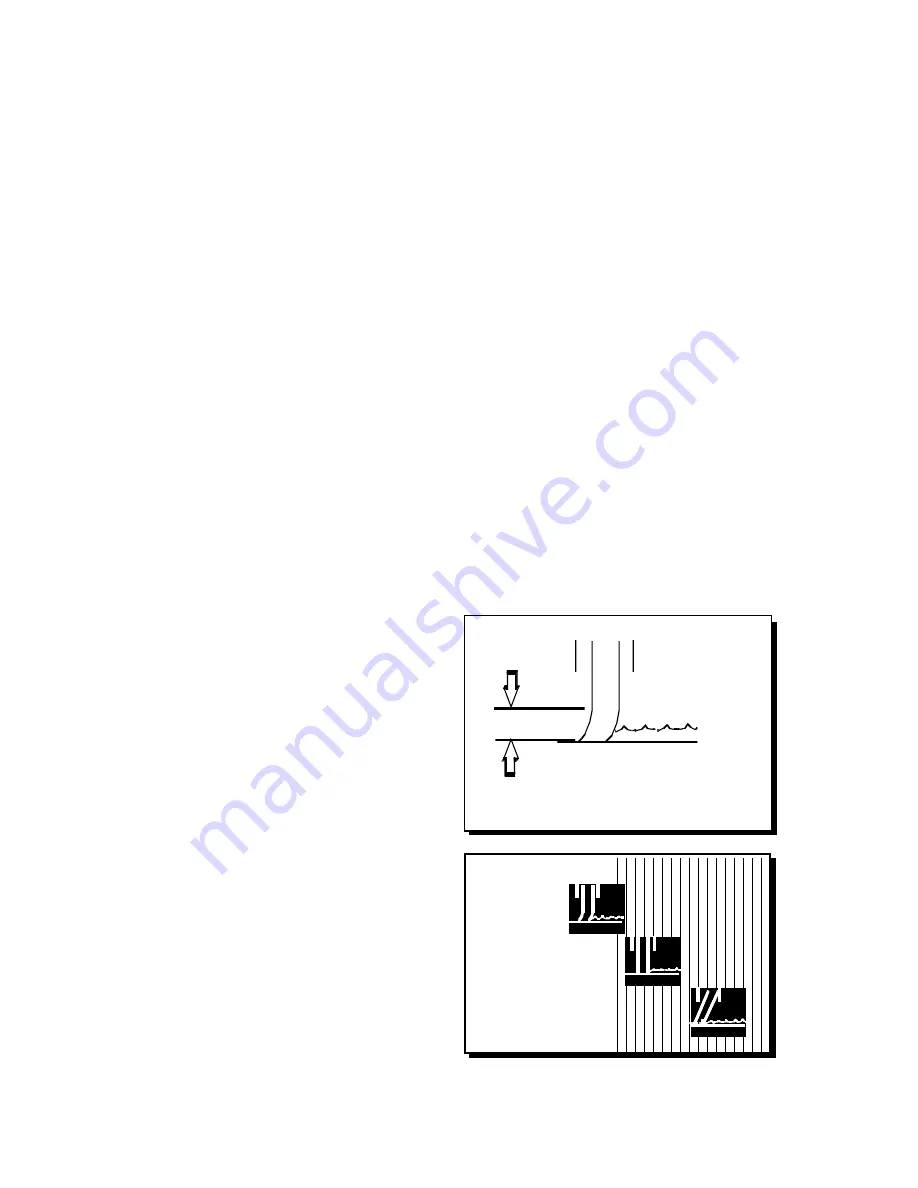

3/8”

PROPER DEFLECTION OF SQUEEGEE BLADE

SQUEEGEE SIDE VIEW OF BLADES

CORRECT

NOT ENOUGH

TOO MUCH

SQUEEGEE DEFLECTION