MAINTENANCE

CUTTER 24V 86036830 06/20/07

4-9

!

WARNING

6. SOLUTION

STRAINER

The solution strainer is located in front of the left

front wheel. The solution strainer protects the

solenoid valve from debris. If there is little or no

solution flow to the ground, check the strainer for

debris. Drain the solution tank and clean the

solution strainer. To remove the strainer, turn the

bottom part of the strainer counterclockwise until

the bottom is separated. Clean out the debris

from the wire mesh and re-assemble. Make sure

the O-ring gasket is in place when re-assembled

7. BRUSH

MOTOR

Do not use a pressure washer to clean around

the brush motors. Use tap pressure only.

CHANGING BRUSH MOTORS

1.

With the scrub deck in the stored position,

disconnect brush motor wiring connector from

harness.

2.

Remove shrouds from scrub deck to access and

remove scrub brushes or pad drivers.

3.

Remove retaining bolt, lock washer, flat washer

and star drive from brush motor shaft.

4.

Remove 4 brush motor mounting bolts located

under scrub deck.

5.

Remove brush motor.

6.

Reverse steps to install.

BRUSH MOTOR CARBON BRUSH

REPLACEMENT

1.

Scribe alignment mark on motor barrel to motor

cap. Remove two bolts.

2.

Remove end cap from motor.

NOTE: Motors contain two wave washers in cap.

Do not lose these.

3.

Release brush from spring tension. Remove

screw connecting brush wire lead to brush

holder. Clean brush holder to insure free

movement.

4.

Retract spring and install new brush. Install

connector screw and lead.

5.

When all new brushes are installed. Place all in

retracted position, held into brush holder by

spring tension.

6.

Carefully place end cap onto bearing on motor

shaft.

NOTE:

Use care to assure wave washer

alignment.

7.

With end cap in partially installed position,

release all brushes to contact position with

motor commutator.

NOTE:

Failure to insure all brushes are

released will result in motor failure.

8.

Reset end cap and realign with scribe marks

on motor barrel. Reinstall the two attach bolts

from cap into base.

9.

Maintain alignment between motor barrel base

and cap.

Summary of Contents for Saber Cutter 10052360

Page 12: ...CONTROLS CUTTER 24V 86036830 06 20 07 3 5 3 5 8 6 13 9 2 12 11 15 1 14 7 10 4 16 ...

Page 34: ...CONTROL HANDLE CUTTER 24V 86036830 06 20 07 11 9 6 10 8 7 4 5 2 3 1 5 1 ...

Page 36: ...COVER FRONT TANK MOUNT CUTTER 24V 86036830 06 20 07 10 9 8 7 5 1 2 6 2 3 3 5 3 ...

Page 38: ...COVER TOP TANK MOUNT CUTTER 24V 86036830 06 20 07 8 5 7 1 2 3 4 3 5 3 6 3 9 10 11 5 5 ...

Page 40: ...DECAL CUTTER 24V 86036830 06 20 07 1 2 3 5 6 7 4 5 7 ...

Page 44: ...LIFT HANDLE CUTTER 24V 86036830 06 20 07 8 6 1 7 2 1 9 4 5 3 5 11 ...

Page 50: ...SCRUB BRUSH PAD DRIVER 3 5 1 8 9 4 6 5 7 2D 2E 2A 2C 2B CUTTER 24V 86036830 06 20 07 5 17 ...

Page 54: ...SCRUB DECK MOTORS CUTTER 24V 86036830 06 20 07 5 21 8 6 7 9 10 4 5 3 2 1 ...

Page 66: ...SOLUTION CUTTER 24V 86036830 06 20 07 7 2 3 8 4 10 9 1 5 13 12 11 10 4 6 5 33 ...

Page 72: ...VACUUM CUTTER 24V 86036830 06 20 07 4 3 2 7 8 9 6 5 1 2 1 5 39 ...

Page 74: ...WHEELS AND FRAME CUTTER 24V 86036830 06 29 11 5 41 4E 4D 6 8 7 9 10 1 2 5 4A 4C 3 4B 11 ...

Page 76: ...WIRING BATTERY CUTTER 24V 86036830 02 10 09 5 43 1 2 3 4 5 9 6 7 8 1 11 10 12 13 ...

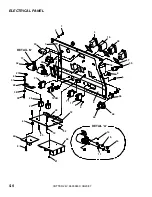

Page 83: ...CUTTER 24V 86036830 06 20 07 5 50 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 86: ...EMERGENCY STOP OPTION CUTTER 24V 86036830 06 20 07 1 5 53 ...