17

Operations

Normal Scrubbing

Plan the scrubbing pattern in advance. The longest

track is around the perimeter of the area to be cleaned.

For efficient operation, the runs should be the longest

possible without turning, stopping, or raising and

lowering scrub deck/squeegee.

NOTE: In order to achieve the best possible results,

the area which is to be cleaned should be swept

before scrubbing. Large debris, strings & wire must

be removed to prevent being caught in brushes or

squeegee.

To Begin Scrubbing

When operating the machine around people, pay

close attention for unexpected movement. Use

extra caution around children.

Flammable liquids and/or reactive metals can

cause explosions or fire! Do not pick up.

1.

Turn the machine power on.

2.

Lower the squeegee.

3.

Turn the vacuum on.

4.

Lower the scrub brushes to the floor.

5.

Turn the scrub brushes on (brushes will start when

machine is propelled).

6.

Drive machine forward to begin scrubbing.

NOTE: Shut machine off immediately if water or foam

is expelled from the machine.

7.

Adjust the speed of the machine, solution flow and

scrub brush pressure as necessary.

NOTE: Once solution flow rate is set it is not

necessary to shut off solution when stopping

scrubbing. Solution flow is automatically shut off

when brush motors stop. When brush motors are

activated, flow automatically resumes.

To Stop Scrubbing

1.

Release the propel levers.

2.

Turn the scrub brushes off.

3.

Raise the scrub brushes.

4.

Raise the squeegee.

5.

Turn the vacuum off.

6.

Turn the machine power off.

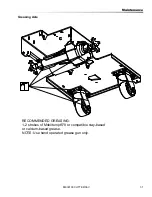

INEFFICIENT SCRUBBING PATH

RECOMMENDED SCRUBBING PATH

86039100 CUTTER 36V

Summary of Contents for Saber Cutter 10052400

Page 12: ...12 Operations Controls 86039100 CUTTER 36V 14 10 4 1 13 5 2 9 3 6 8 15 7 16 11 12 12 ...

Page 34: ...34 Notes 86039100 CUTTER 36V ...

Page 35: ...35 PARTS Parts 86039100 CUTTER 36V ...

Page 36: ...36 9 1 2 3 4 6 8 7 5 10 11 86039100 CUTTER 36V Control Handle ...

Page 38: ...38 5 6 3 7 1 2 3 4 86039100 CUTTER 36V Cover Front Tank Mount ...

Page 40: ...40 8 7 11 3 4 3 2 9 5 3 6 5 3 1 10 86039100 CUTTER 36V Cover Top Tank Mount ...

Page 42: ...42 1 2 3 5 6 8 4 86039100 CUTTER 36V Decal ...

Page 46: ...46 Lift Handle 2 3 4 5 8 9 2 7 6 1 86039100 CUTTER 36V ...

Page 48: ...48 Lift Handle Linkage 2 12 7 4 5 6 8 11 3 10 9 13 15 1 5 14 86039100 CUTTER 36V ...

Page 56: ...56 Scrub Deck Motors 5 4 3 10 9 8 7 6 2 1 86039100 CUTTER 36V ...

Page 62: ...62 Scrub Deck Lift Linkage 1 2 3 4 5 6 7 3 2 7 5 3 7 7 6 4 86039100 CUTTER 36V ...

Page 64: ...64 Scrub Deck Lift 7 15 17 4 13 5 13 2 14 14 8 3 6 10 9 11 1 1 13 16 86039100 CUTTER 36V ...

Page 66: ...66 Solution 13 11 9 10 HOSE FROM FILTER ASM 8 7 4 3 1 12 6 5 2 86039100 CUTTER 36V ...

Page 68: ...68 Solution 9 1 5 3 TO SOLUTION TANK 2 5 11 12 10 13 4 6 2 7 8 86039100 CUTTER 36V ...

Page 74: ...74 Vacuum 8 7 10 9 3 6 5 1 2 3 1 2 4 4 5 14 12 11 86039100 CUTTER 36V ...

Page 78: ...78 Wiring Battery 1 2 3 4 5 9 6 7 8 1 11 10 12 86039100 CUTTER 36V ...

Page 86: ...86 Notes 86039100 CUTTER 36V ...

Page 87: ...87 OPTIONS Options 86039100 CUTTER 36V ...

Page 90: ...90 86039100 CUTTER 36V Emergency Stop 1 ...

Page 95: ...95 86039100 CUTTER 36V ...