MAINTENANCE

SCX364 86037150 1/17/07

4-14

TO ADJUST FRONT SQUEEGEE

DEFLECTION

1.

Choose a smooth, level surface. Lower the front

squeegee and deck and drive forward at least 2

feet (60cm) until the desired brush pressure is

obtained.

2.

With the squeegee down, stop the machine. Do

not allow machine to roll back.

FOR SAFETY: Before leaving or servicing

machine; stop on level surface, turn off machine

and remove key.

3.

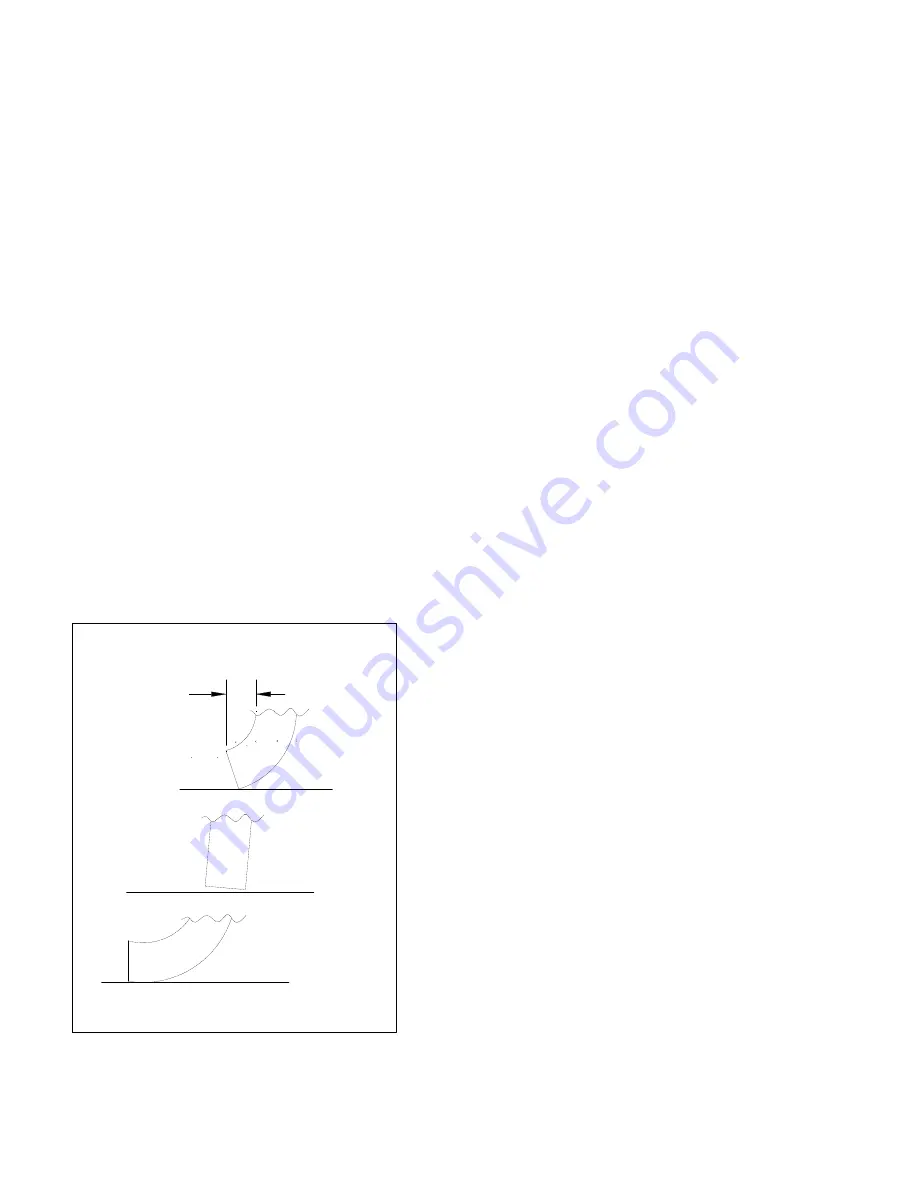

Observe the amount of squeegee deflection. It

should deflect 1/4 in. (6.25mm) across the entire

width of the squeegee.

4.

To increase the squeegee deflection, loosen the

two knobs on the linkage and lower the

squeegee and bracket, then retighten. To

decrease the deflection, loosen the two knobs

on the linkage and raise the squeegee and

bracket, then retighten.

5.

Turn on the key switch. Raise, then lower

squeegee and deck assembly. Drive forward at

least 2 feet (60cm) until the desired brush

pressure is obtained.

6.

Repeat steps 2 through 4 until deflection of

1/4 in. (6.25mm) is reached.

1/4"

(6.25mm

)

CORRECT

NOT ENOUGH

TOO MUCH

SQUEEGEE DEFLECTION

SIDE VIEW OF SQUEEGEE BLADE