TIONS

EXTENSION CORDS:

PREPARING FOR OPERA

If

an

extension cord is used, the wire size

must

be at least one

size larger than the power cord on the machine, and the cord

must

be

a type

HOW IT OPERATES

The

TRIDENT COMPACT

is a walk-behind scrubber.

The main scrubbing components include a

tank,

single disc-type brush or pad, a rear squeegee and a vac-

uum motor.

Detergent solution and water flow from the solution

tank

to

the scrub brush. The rotating brush scrubs the floor. As the

machine moves forward, the rear squeegee collects the dirty

solution and channels it into

the vacuum

of

the squeegee pickup

hose. The pickup hose deposits the dirty solution into the re-

covery tank.

PREPARING FOR OPERATION

(PERFORM

DAILY MAINTENANCE AS SHOWN ON

PAGE 7.)

Fill Solution Tank

1.)

2.)

Remove cover and fill. (see item 19, page

14)

Use a clean bucket or hose to fill the tank

with water.

3.)

Add a cleaning concentrate for use in automatic floor

scrubbers. Closely follow the manufacturer’s instructions

found on container. Read ingredients listed on the container

to ensure compatible chemicals are used.

Use only the suitable chemicals listed below. Using incom-

patible chemicals may damage the machine. Damages of

this type are not covered under the

Three Year

Protection Plan. Carefully read ingredients on manufac-

turer’s label before using any product in this machine.

I

I

SUITABLE

INCOMPATIBLE

CHEMICALS

CHEMICALS

Alkalis

Aldehydes

Agents

Carbon Tetrachloride

Detergents

Chlorinated Hydrocarbons

Hydroxides

Methyls (MEK)

Phenols

Trichlorethylene

D-Limonene

4.)

Plug the power cords together and twist into locked

position. Attatch the power cord to the yellow strain

relief as shown. Plug power cord into a properly

grounded wall outlet.

5.)

Turn vacuum motor switch on and

off to make sure

there is electrical power at machine.

OPERATING THE MACHINE

(PERFORM

SHOWN ON

PAGE 7.)

1.

Adjust the operator control handle to a

comfortable position. (see item

3,

page

6)

2.

Switch on main power switch. (see item page 5)

3.

Release solution. (Pull solution control lever

rearward.) (see item

6,

page

6)

NOTE: The

amount of solution can be regulated during

operation depending on the type of floor and the

traverse speed

of

the machine. Pulling the lever

farther rearward releases more solution.

4.

Switch on brush drive motor. (see item 1, page

6)

5.

Switch on vacuum motor. (see item 2, page 6)

6.

Lower scrub deck. Pull scrub deck lift lever

rearward. (see item 8, page

6)

is stationary.

7.

Lower squeegee. Pull squeegee lift lever

back. (see item

7,

page

6)

NOTE:

Adjust

squeegee as shown on page 9.

8.

Move machine forward bv

even

pressure on the main

.

Forward motion is

assisted by the scrubbing action of the

driver.

Take extra care not to run machine over cord or

catch cord on squeegee when turning.

7.

Plan your cleaning route to work away from the

electrical source. Move machine forward at a

steady pace

98447 7/1/97

5

Summary of Contents for TRIDENT COMPACT TC20E

Page 12: ...TANKS AND FRAME 22 I 2 REAR VIEW TC20E 98447 12 01 99...

Page 14: ...SQUEEGEE ASSEMBLY A 58 7 35 l l SQUEEGEE SUB ASSEMBLY 35 t v 19 7 9 74 TCPOE 98447 1I l 1 99...

Page 16: ...VALVEGROUP 8 FROMSOLUTIONTANK 10 SOLUTIONDRAIN HOSE w Detail A 16 TCPOE 98447 3 26 98...

Page 18: ...SCRUBDECKASSEMBLY 23 I 18 TCPOE 98447 3 26 98...

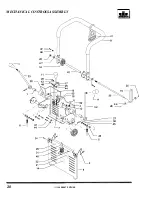

Page 20: ...MECHANICAL CONTROLSASSEMBLY n 1 1 37 44 47 32 44 9 26 Q ____ 20 TCPOE 98447 03 13 00...

Page 22: ...CONTROLPANEL ASSEMBLY 21 12 REAR VIEW CONTROL PANEL 22 TC20E 98447 2 4 99...