MAINTENANCE

VACUUM

MOTOR

2.

3.

4.

After the machine has been used for any wet pick-

up, allow the vacuum motor to

run

1-2 minutes, to

help reduce moisture build-up in the vacuum mo-

tor. Drying out the vacuum motor after each use

will extend the life of your vacuum motor.

Disconnect battery leads and remove batteries

from compartment.

Remove (6) bolts holding

motor/ plate

assembly to recovery tank.

Disconnect

motor lead from connector

and

lift

out

plate assembly.

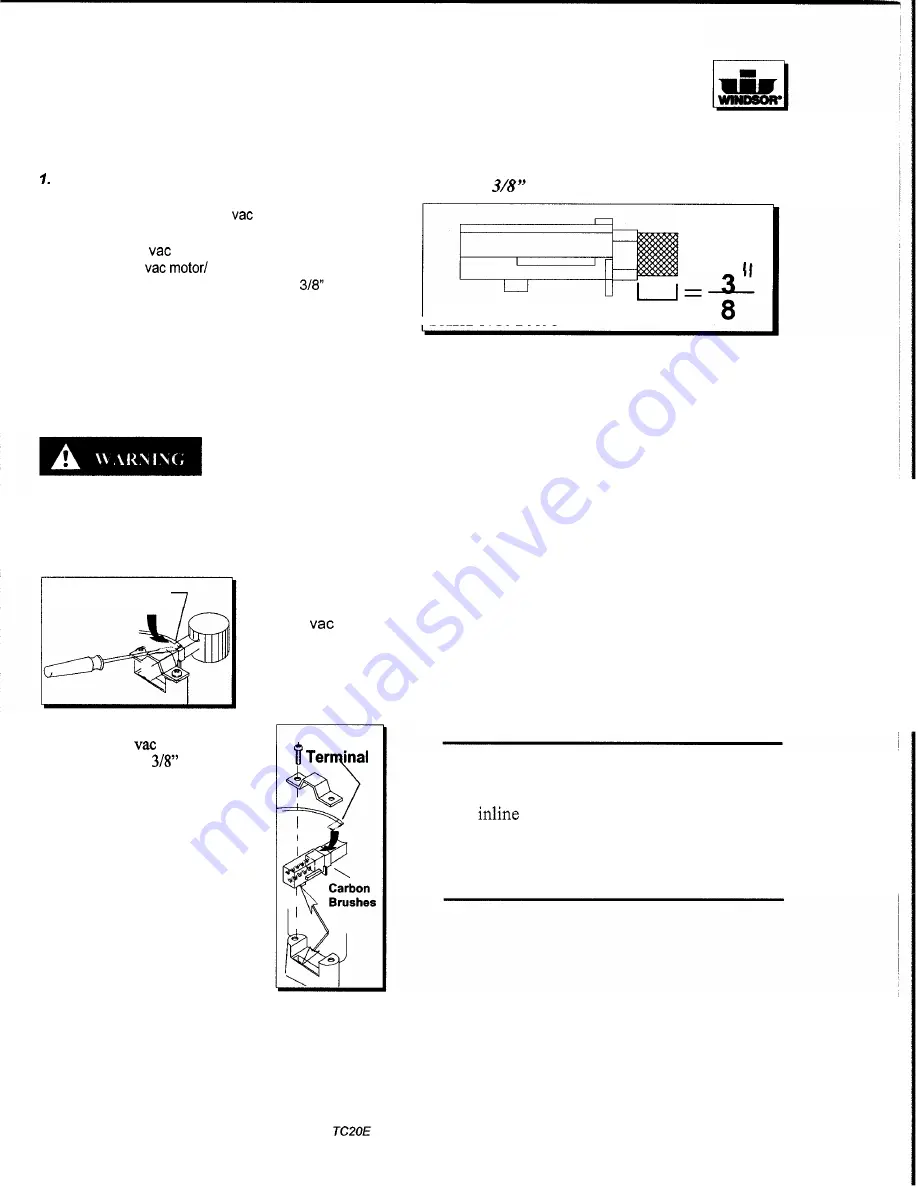

Check motor brushes. When wom to

replace

both brushes.

Hazardous Voltage. Shock can result. Discon-

nect batteries before working on machine. Only

qualified personnel should work inside ma-

chine.

Wire Terminal

Important:

Replace carbon

motor brushes

if

worn

down to

in length.

These brushes wear quicker

as

the

length shortens due to increased

heat.

Spring inside brush housing will

damage motor if brushes are al-

lowed to completely wear away

Note: Place stop

in groove.

Important:

When replacing

carbon

motor

brushes loosen wire

terminal

BEFORE

re-

moving

screws

on

bracket.

Wire

NOTE: Periodically check the length of the car-

bon brushes. Replace carbon brushes which are

less than

long.

I

PART NO. 14695

BRUSH

Brush Installation:

1.

Slide brush or pad driver under drive plate.

2.

Align one metal lug on the brush or

pad driver with the scrub deck sight hole and a

keyhole in the drive plate.

3.

Raise the brush or pad driver upward

and twist clockwise until locked.

Brush Removal:

1.

Raise brush or pad driver off floor.

2.

Reach under brush or pad driver and rotate

so

that the metal lug in the drive plate is visible

through the scrub deck sight hole.

3.

Quickly twist brush or pad driver counterclockwis

to release.

SOLUTION STRAINER

1.

An

solution strainer is located under chassis

behind left wheel. Remove sediment bowl and

screen periodically and rinse clean with hot water.

Be careful not to misplace the gasket.

8

98447 7/1/97

Summary of Contents for TRIDENT COMPACT TC20E

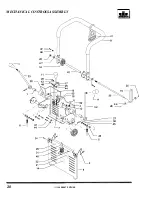

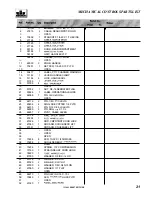

Page 12: ...TANKS AND FRAME 22 I 2 REAR VIEW TC20E 98447 12 01 99...

Page 14: ...SQUEEGEE ASSEMBLY A 58 7 35 l l SQUEEGEE SUB ASSEMBLY 35 t v 19 7 9 74 TCPOE 98447 1I l 1 99...

Page 16: ...VALVEGROUP 8 FROMSOLUTIONTANK 10 SOLUTIONDRAIN HOSE w Detail A 16 TCPOE 98447 3 26 98...

Page 18: ...SCRUBDECKASSEMBLY 23 I 18 TCPOE 98447 3 26 98...

Page 20: ...MECHANICAL CONTROLSASSEMBLY n 1 1 37 44 47 32 44 9 26 Q ____ 20 TCPOE 98447 03 13 00...

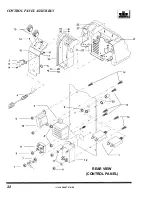

Page 22: ...CONTROLPANEL ASSEMBLY 21 12 REAR VIEW CONTROL PANEL 22 TC20E 98447 2 4 99...