5

Assembly & Installation

Things you need —

Screwdrivers (Phillips and slot)

1-3/4” hole saw

7/16” wrench

ABS glue

Drill with 1/8” bit

Tape measure

Non-hardening sealant

(Check manufacturer’s specifications for

compatibility with your roof material.)

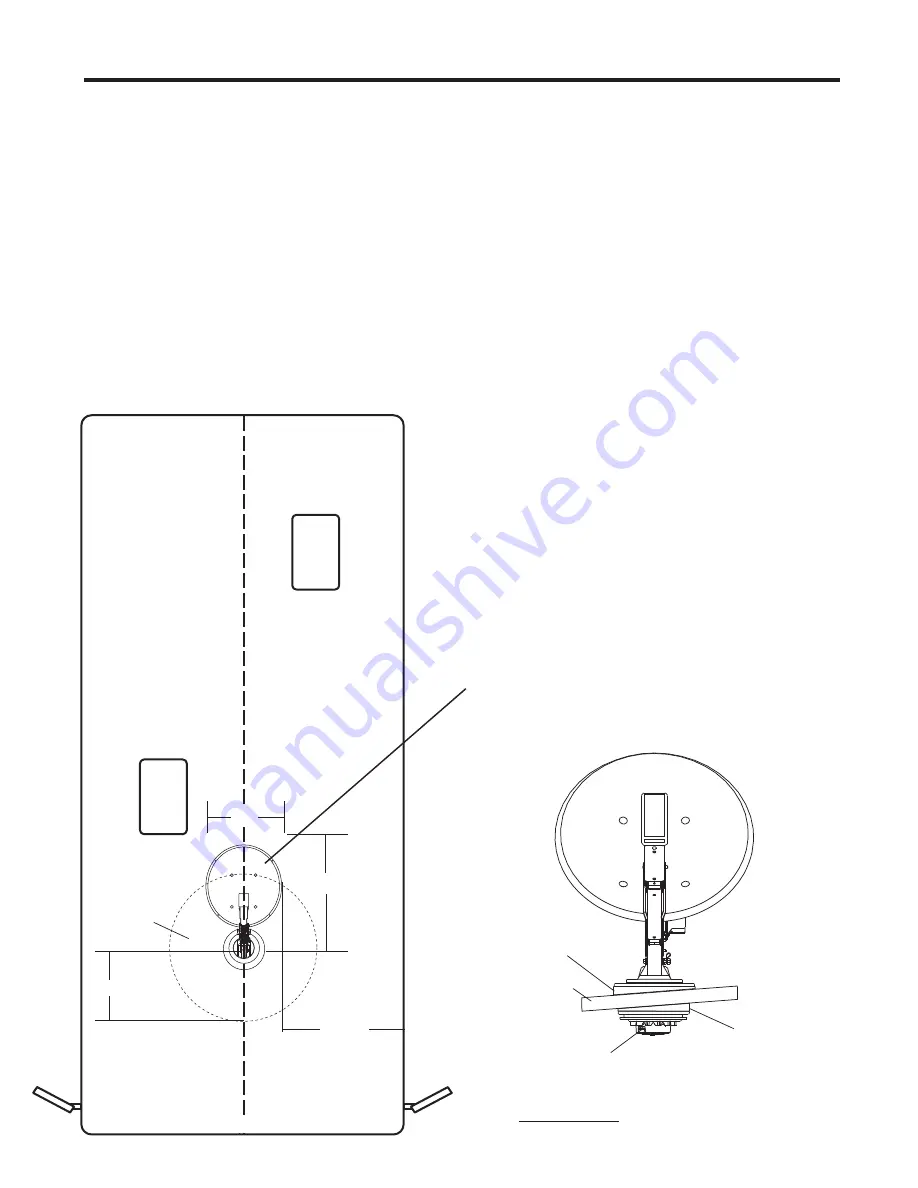

STEP 1.

Choose a location on the roof for dish that will allow dish to raise and rotate without

interfering with other roof-mounted equipment. Make sure inside ceiling plate is easily acces-

sible, and with no obstructions that would interfere with operation.

Figure1 shows minimum distance (10”) antenna should be located from edge

of vehicle roof. It is recommended that you check with your dealer or manufacturer

for provisions that may have been made in the roof for antenna mounting; a

reinforced roof area or pre-wire installation from the factory.

NOTE:

The system must be level for proper operation!

Winegard Model RW-5000 roof wedge with gasket is available. If inside roof wedge is

needed, Winegard’s RW-1000 can be trimmed to fit ceiling plate.

MEASURE THE THICKNESS OF THE ROOF

NOW

. Measure the outside roof covering

through ceiling material. You will need this

information when installing ceiling plate/

directional handle assembly.

STEP 2.

Position template on roof (see insert page

of this manual).

CAUTION: DO NOT drill through

wiring.

Carefully

drill a 1-3/4” hole through roof and

ceiling of vehicle.

Inspect hole to make sure

wiring is intact. (Roof template, see insert.)

It is highly recommended that the antenna be

mounted on roof center line. Do not mount

antenna closer than 10” from edge of roof.

NOT TO SCALE

RW-5000

Roof Wedge

with gasket

Vehicle Roof

Antenna Controls

Interior

Roof Wedge

(Optional)

FIGURE 3

Rev. 7/04

Center Roof Line

MINIMUM

10”

17” RADIUS

26”

19.50”

34” DIAMETER

OPERATING

AREA

FRONT OF VEHCILE

z

Summary of Contents for RM-4600

Page 11: ...Parts List 11 Rev 4 16 ...

Page 12: ...Parts List 12 ...

Page 13: ...Notes 13 ...

Page 14: ...Notes 14 ...

Page 15: ...Notes 15 ...