2

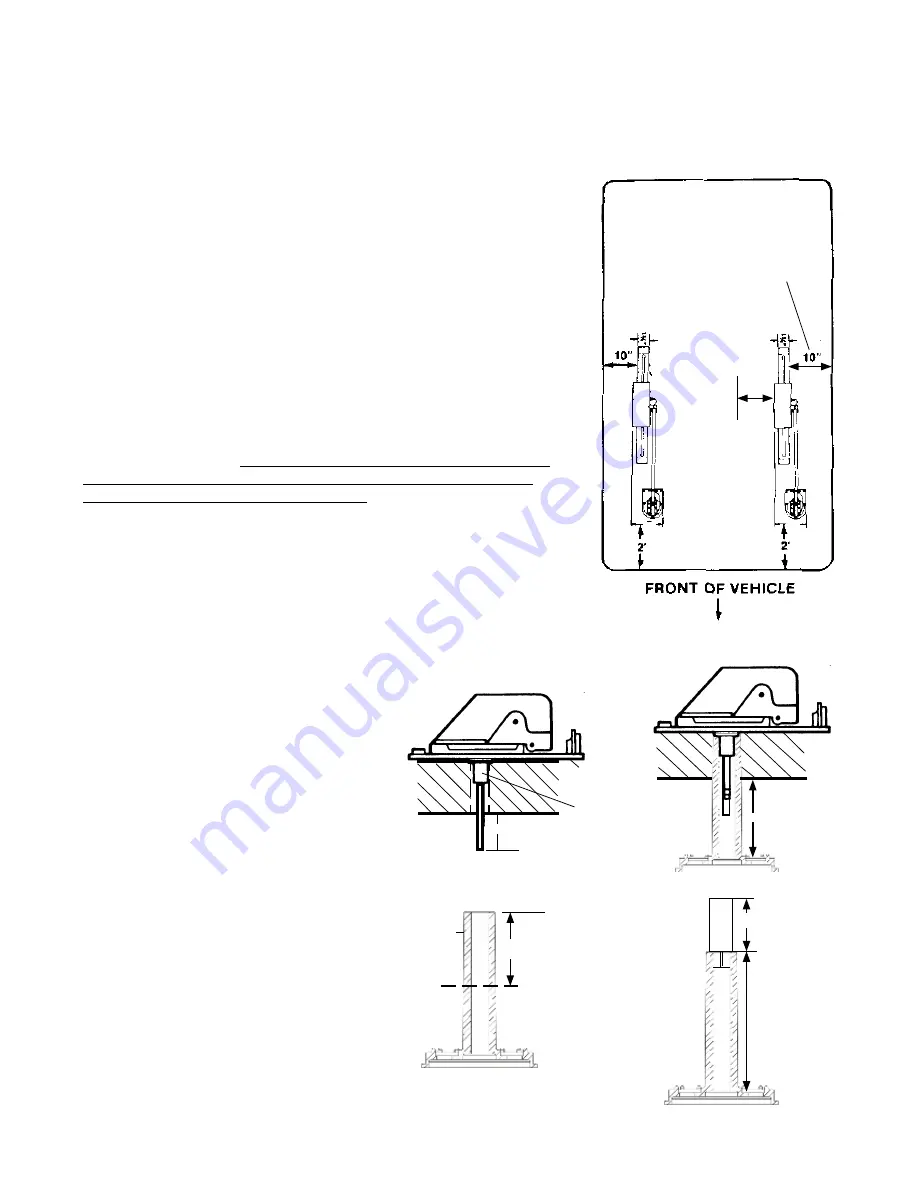

NOTE: Figure 1 shows the minimum distance the mount can be

located from edge of vehicle roof or nearest obstruction. Check with

your dealer or the manufacturer for information about options in the

roof for mounting the antenna. A reinforced roof area, or a prewired

coax cable, may be available. For sloped/round roofs, use Winegard

Model RW-2000 exterior roof wedge, to level installation. An interior

wedge, IW-5000, is also available.

STEP 2:

Using template on our website at http://www.winegard.com/

kbase/upload/sensar_template.pdf drill 1-3/4" hole through roof and

ceiling of vehicle. Be careful not to damage any wiring between roof and

ceiling.

STEP 3:

Drill 1/2" hole for

cable entry through roof of vehicle only

. DO

NOT DRILL THROUGH CEILING. Route cable through ceiling and wall to

power supply location.

STEP 4:

The mount is designed to fit roofs from 1" to 4-3/4" thick. As

supplied, the mount will fit a roof 4-3/4" thick. If roof is less than 4-3/4"

thick, cut elevating shaft and directional handle to size, steps shown

in figures 2, 3, 4 and 5.

If roof is more than 4-3/4" thick (max. 7"), a

directional handle extension is needed. Order Winegard Model

EK-1036, Directional Handle Extension.

IMPORTANT

:

The handle and extension must be glued together

after

checking that you have the correct length

.

The handle will not work

properly if it is not glued together! (PVC glue is recommended; for your

safety, use according to manufacturer's directions.)

NOTE: If using roof wedge RW-2000 or interior wedge IW-5000, put in

place before installing base plate or interior hardware.

2452013-Installation/Operation

STEP 1:

Choose location for antenna. Figure 1 illustrates placement of the Sensar, showing it in travel position.

You must be able to raise and rotate antenna without interfering with other roof-mounted equipment. Make sure

inside ceiling area is clear to mount ceiling plate.

3¾"

10" Minimum

Distance

3¾"

∗

10"

To Nearest

Obstruction

STEP 5:

Center elevating shaft in hole on

roof. Temporarily secure base plate to roof

with two screws provided.

(Do not apply

sealant at this time).

Inside unit, make a

mark on the shaft 1-1/2” below ceiling and cut

shaft on this mark. See figure 2.

After cutting elevating shaft, push directional

handle up into ceiling over shaft being careful

to align keys inside directional handle onto

keyways on bottom of gear housing.

(NOTE:

The keys only line up one way; do not force.

TIP: Pointer on directional handle should

point toward back of coach if properly

installed.)

Make sure directional handle is snug

against bottom of baseplate. Measure distance

between the bottom of the recess on the handle

to the ceiling. See figure 3. Pull handle back

down and transfer this dimension to the shaft

end of the directional handle. Mark it and cut it

off here, fig. 4.

If EK-1036 (directional handle extension)

is

used,

DO NOT CUT EK-1036 extension.

Cut

excess length from directional handle only. The

handle and extension must be glued together

after checking that you have the correct length,

fig. 5

.

10"

10"

FIGURE 1

FIG. 4

Measure from

the recess on

top of handle

to the ceiling.

FIG. 2

1-1/2"

FIGURE 3

FIGURE 5

EK-1036

Extension

DO NOT CUT

extension

Cut excess

length from

directional

hande

Measure

from bottom

of recess on

top of handle

Bottom of

Baseplate

Bottom

of Gear

Housing

Directional Handle

Shaft

End

*

Transfer the

measurement

from Fig. 3 to

shaft end and

cut off.

*

2-1/4"