Maintenance

4103

−

3/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

D

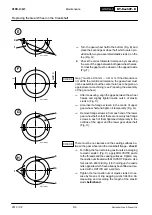

Before assembling, the centring diameter of the crankshaft flange as well as

the centre hole of the gear wheel with the corresponding flange faces must be

well cleaned

and degreased

(Fig. B). Do not use neither oil nor MOLYKOTE.

All surfaces must be in faultless condition.

Remark:

The assembly of the gear wheel must be carried out carefully, since rela-

tively small faults could have a negative influence on the operating performance of

all gear wheels of the drive.

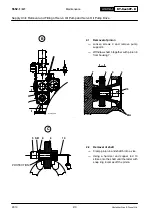

3.

Assembly of 2-part gear wheel

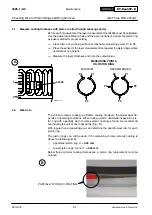

The connection consists of four elastic studss 3, each of them comprising two

castle nuts 4 and bases 5.

⇒

Before assembling the gear wheel halves, fit two

elastic studs crosswise into each half.

⇒

Fasten a base 5 and a castle nut 4 on

either side

of each elastic stud.

The projection ‘X’ of the elastic stud with respect to

the castle nut must be 7 mm.

⇒

Before fitting the castle nut, degrease the thread

and apply LOCTITE 262 to it.

⇒

In addition, secure the castle nut with a split pin to

prevent it from slipping when tightening the elastic

studs afterwards.

D

Wait one or two days before tightening the elastic

studs in order to ensure thorough curing of the

LOCTITE.

C

X

5

4

001.168/97

MOLYKOTE

LOCTITE 262

DEGREASE

SPLINT PIN

4

5

3

9

1

Remark:

The castle nut secured with LOCTITE and a

split pin must be fitted in such a way that the elastic stud

can be tensioned together with the castle nut opposite,

as shown in Fig. I.

3.1

Work sequence

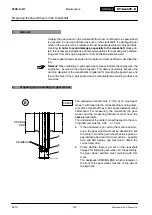

⇒

Turn the crankshaft so that the mark on the crank-

shaft flange is approximately horizontal with re-

gard to the crankshaft centre line.

⇒

Put one gear wheel half with two pre-assembled

elastic studs 3 on the centring diameter of the

crankshaft flange in such a way that the joint face

of the gear wheel coincides with the mark on the

crankshaft flange. The designation DRIVING END

located on the front of the gear wheel must be on

the side of the flywheel.

⇒

Insert flange screws 6 each in the centre and at

both ends of the gear wheel half 1 and tighten them

temporarily.

D

1

6

3

001.167/97

2013

Replacing the Gear Wheel on the Crankshaft

Summary of Contents for WARTSILA RT-flex58T-D

Page 8: ...Intentionally blank ...

Page 10: ...Intentionally blank ...

Page 12: ...Intentionally blank ...

Page 14: ...Intentionally blank ...

Page 20: ...Intentionally blank ...

Page 32: ...Intentionally blank ...

Page 58: ...Intentionally blank ...

Page 66: ...Intentionally blank ...

Page 72: ...Intentionally blank ...

Page 84: ...Intentionally blank ...

Page 88: ...Intentionally blank ...

Page 92: ...Intentionally blank ...

Page 120: ...Intentionally blank ...

Page 122: ...Intentionally blank ...

Page 124: ...Intentionally blank ...

Page 132: ...Intentionally blank ...

Page 136: ...Intentionally blank ...

Page 148: ...Intentionally blank ...

Page 152: ...Intentionally blank ...

Page 156: ...Intentionally blank ...

Page 168: ...Intentionally blank ...

Page 176: ...Intentionally blank ...

Page 186: ...Intentionally blank ...

Page 192: ...Intentionally blank ...

Page 196: ...Intentionally blank ...

Page 200: ...Intentionally blank ...

Page 214: ...Intentionally blank ...

Page 234: ...Intentionally blank ...

Page 238: ...Intentionally blank ...

Page 242: ...Intentionally blank ...

Page 256: ...Intentionally blank ...

Page 264: ...Intentionally blank ...

Page 272: ...Intentionally blank ...

Page 280: ...Intentionally blank ...

Page 282: ...Intentionally blank ...

Page 290: ...Intentionally blank ...

Page 296: ...Intentionally blank ...

Page 300: ...Intentionally blank ...

Page 312: ...Intentionally blank ...

Page 314: ...Intentionally blank ...

Page 318: ...Intentionally blank ...

Page 334: ...Intentionally blank ...

Page 340: ...Intentionally blank ...

Page 348: ...Intentionally blank ...

Page 352: ...Intentionally blank ...

Page 356: ...Intentionally blank ...

Page 358: ...Intentionally blank ...

Page 362: ...Intentionally blank ...

Page 366: ...Intentionally blank ...

Page 370: ...Intentionally blank ...

Page 380: ...Intentionally blank ...

Page 384: ...Intentionally blank ...

Page 386: ...Intentionally blank ...

Page 392: ...Intentionally blank ...

Page 402: ...Intentionally blank ...

Page 412: ...Intentionally blank ...

Page 414: ...Intentionally blank ...

Page 438: ...Intentionally blank ...

Page 440: ...Intentionally blank ...

Page 444: ...Intentionally blank ...

Page 454: ...Intentionally blank ...

Page 498: ...Intentionally blank ...