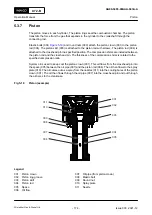

5.3.2.1

Steel spring damper

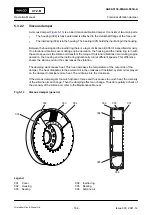

) is a tuned torsional vibration damper. It consists of two main

parts:

•

The inner part (inner star (005) and spring pack (004)) is attached to the crankshaft flange

at the free end.

•

The outer part (side plates (001), clamping ring (002) and intermediate pieces (003)) is

connected with spring packs (004) to the inner part.

The damper is supplied with pressurized system oil that fills the chambers between the inner and

outer part. The usual setting value for the oil supply pressure is 2.8 bar. But the setting value can

be different, refer to the specification of the damper manufacturer.

If torsional vibrations move the steel springs, oil is pressurized on one side of the oil chambers

and pushed through small clearances to the other side of the chambers. This small oil flow creates

the damping effect of the damper. The combined effect of spring stiffness and damping decreases

the torsional vibrations in the shafting system. The damping work causes heat which is dissipated

by the oil flow. The oil drains into the crankcase.

The optional damper monitoring system monitors the dynamic twist in the damper and the oil

supply pressure.

Fig 5-12

Steel spring damper (generic)

001

002

003

004

005

001

001

002

005

006

001

Legend

001

Side plate

004

Spring pack

002

Clamping ring

005

Inner star

003

Intermediate piece

006

Sealing

X72-B

AA00-3130-00AAA-043A-A

Operation Manual

Torsional vibration damper

Winterthur Gas & Diesel Ltd.

- 163 -

Issue 003 2021-12