PROCEDURE

1

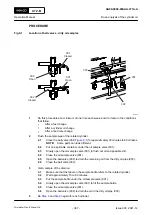

Flush the sample pipe.

NOTE:

Use the sample point related to the engine as follows:

•

For an engine with servo oil filter, do as follows:

○

Get a sample from the sample point at the engine inlet.

○

If the analysis shows unusual values, get a sample from the sample

point after the servo oil filter.

•

For an engine without servo oil filter, get the sample from the sample point

at the engine inlet.

1.1

Put an applicable container under the sample valve.

1.2

Slowly open the sample valve to flush out oil and possible dirt.

1.3

Close the sample valve.

1.4

Discard the oil correctly.

2

Get an oil sample.

2.1

Put the sample bottle under the sample valve.

2.2

Slowly open the sample valve to fully fill the sample bottle.

NOTE:

The necessary quantity of oil is as follows:

•

100 ml for regular oil analysis

•

5 l for FZG and particle count analysis.

2.3

Close the sample valve.

2.4

Close the sample bottle tight.

3

Write the data that follows on the sample bottle:

•

Name of the ship

•

Type and serial number of the engine

•

Date of the sampling

•

Location of the sample point

•

Operating hours of the oil and of the engine

•

Brand and type of the oil.

4

again for the other sample point.

5

Send the sample bottles in an applicable package to a laboratory for analysis.

6

Do the procedures related to the results, refer to section

[section not applicable for this

engine]

or to the document “Lubricants” on the WinGD website (https://www.wingd.com/).

CLOSE UP

•

None

X72-B

AA00-0000-00AAA-371B-A

Operation Manual

Do an analysis of the system oil

Winterthur Gas & Diesel Ltd.

- 365 -

Issue 003 2021-12