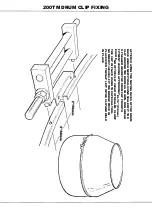

200TM DRUM CLIP FIXING

A

FT

E

R

C

O

A

T

IN

G

T

H

E

M

A

T

IN

G

F

A

C

E

S

O

F T

H

E

D

R

U

M

B

A

S

E

A

N

D

C

O

N

E

W

IT

H

S

IL

IC

O

N

E

S

E

A

LE

R

F

IT

T

H

E

C

LI

P

A

R

O

U

N

D

T

H

E

D

R

U

M

A

S

S

H

O

W

N

. R

U

N

A

B

E

A

D

O

F S

E

A

LE

R

IN

S

ID

E

T

H

E

D

R

U

M

C

LI

P

P

R

IO

R

T

O

FI

T

M

E

N

T

L

E

A

V

IN

G

A

P

P

R

O

X

IM

A

T

E

LY

6

’’ (

I5

0m

m

)

E

A

C

H

E

N

D

O

F T

H

E

C

LI

P

C

LE

A

R

O

F S

E

A

LE

R

. C

LA

M

P

T

H

E

C

LI

P

IN

P

LA

C

E

U

S

IN

G

T

H

E

S

P

E

C

IA

L T

O

O

L

N

U

M

B

E

R

5

13

20

40

00

. F

IT

T

H

E

B

R

ID

G

E

P

IE

C

E

IN

P

LA

C

E

O

V

E

R

T

H

E

G

A

P

L

E

FT

IN

T

H

E

C

LI

P

A

N

D

W

E

LD

IN

P

LA

C

E

Summary of Contents for 200TM

Page 3: ...WORKSHOP MANUAL 200TM SECTION 1 INTRODUCTION...

Page 6: ...WORKSHOP MANUAL 200TM SECTION 2 REPAIR SERVICE PROCEDURES...

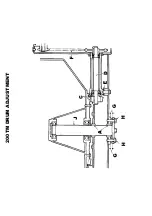

Page 12: ...200TM DRUM ADJUSTMENT...

Page 42: ...WORKSHOP MANUAL 200TM SECTION 3 GENERAL ARRANGEMENT DIMENSIONS...

Page 43: ...GENERAL ARRANGEMENT...

Page 44: ...DIMENSIONS...

Page 45: ...WORKSHOP MANUAL 200TM SECTION 4 SERVICE SCHEDULES LUBRICATION DIAGRAM...

Page 48: ...LUBRICATION POINTS...

Page 49: ...LUBRICANTS...

Page 50: ...WORKSHOP MANUAL 200TM SECTION 5 HYDRAULIC CIRCUIT DIAGRAMS...

Page 51: ...200TM LATER BASIC HYDRAULIC CIRCUIT...

Page 52: ...200TM LATER DRAGLINE BATCHWEIGER HYDRAULIC CIRCUIT...

Page 53: ...WORKSHOP MANUAL 200TM SECTION 6 WIRING DIAGRAMS...

Page 59: ...Hourmeter lamp dwg 04 03 02 12 50 36 Scaled to fit...

Page 60: ...Hourmeter no lamp dwg 04 03 02 12 53 33 Scaled to fit...

Page 62: ...WORKSHOP MANUAL 200TM SECTION 7 NOISE LEVELS...

Page 64: ...WORKSHOP MANUAL 200TM SECTION 8 SPECIAL TOOLS...

Page 65: ...200TM PUNCH VALVE SEAT 200TM SPECIAL TOOL V2003698 CASE HARDEN TO 45 50 ROCKWELL...

Page 66: ...200TM DRUM BLADE DRILLING GUIDE SPECIAL TOOL 200TM 513360100...

Page 67: ...200TM SPECIAL TOOLS...

Page 68: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 69: ...WORKSHOP MANUAL 200TM SECTION 9 HYDRAULIC CONTROL VALVE SERVICE MANUAL...

Page 70: ...PAGE INTENTIONALLY BLANK...

Page 71: ...WORKSHOP MANUAL 200TM SECTION 10 PARTS LISTINGS...

Page 73: ...200TM MAINFRAME AXLES AND STABILISERS...

Page 90: ...200TM 415 VOLT START STOP SWITCH STAR DELTA...

Page 92: ...200TM 415 VOLT START STOP SWITCH DIRECT ON LINE...

Page 98: ...200TM HOPPER...

Page 110: ...200TM WATER TANK FIT SPECIAL WASHER V2004220 BETWEEN ITEMS 11 12...

Page 114: ...200TM DYNAMO AND MOUNTING LISTER PETTER TS1 HS...

Page 118: ...200TM DRAGLINE ASSEMBLY...

Page 120: ...200TM DRAGLINE ASSEMBLY...

Page 124: ...200TM DRAGLINE SHOVEL...

Page 126: ...200TM DRAGLINE FEEDAPRON...

Page 130: ...200TM LISTER PETTER TS1 ELECTRIC START...

Page 132: ...200TM DECALS AND LOGOS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22...

Page 134: ...200TM DECALS AND LOGOS 23 24 25 26 27 28 29...

Page 135: ...200TM SPECIAL TOOLS...

Page 136: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 137: ...WORKSHOP MANUAL 200TM SECTION 11 BATCHWEIGHER MAINTENANCE INSTRUCTIONS...

Page 138: ...MAINTENANCE INSTRUCTIONS HYDRAULIC WEIGHING UNITS WWW WINGET CO UK...

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 146: ......

Page 147: ......