WORKSHOP MANUAL

Winget Mechanically Fed Mixers

Models: 200TM

From 1998

Turn the handwheel and check the drum and trunnion operate correctly and contact

the travel stops without unduly stressing the tilting chain.

Tilting Chain

To access the tilting chain remove the upper and lower chain guards behind the front

plate of the trunnion. The chain is anchored to the trunnion end plate by means of

two split links one in each end of the chain.

To replace the chain, place the drum in the vertical position and engage the

handwheel locking plunger in the lower single hole. Slacken the four setscrews

retaining the tilting bracket and lift the bracket in the slots to release any tension on

the chain, tighten at least one of the setscrews to hold the bracket in place. Separate

the split links and unhook the chain. Reverse the procedure to refit the chain

adjusting the final chain tension by sliding the tilting bracket in the slots. Refit the

guards and check the trunnion contacts the travel stops without unduly stressing the

chain.

Countershaft/Bevel Pinion Drive Chain.

Remove the chain guard from the rear of the trunnion. Crank the engine over until the

chain split link is visible. Disconnect the split link, hook the new chain loosely onto the

split link slowly crank the engine and pull the new chain in place round the

countershaft sprocket. Remove the old chain and link. Loop the new chain round

the sprocket in the bevel pinion shaft and fit the new split link. The open end of the

split end should point away from the normal direction of rotation, which is anti-

clockwise when looking directly at the chain. Check and adjust the chain tension.

(See Bevel Pinion Shaft and Housing). Refit the chain guard.

Bevel Pinion Shaft and Housing

Follow the procedures described earlier and remove the drum, bevel gear guard and

disconnect the countershaft bevel pinion drive chain.

Rotate the trunnion until it reaches its highest point and lock in place. Remove the

gib head key securing the sprocket to the bevel pinion shaft. Remove the bevel

pinion guard, release the tabwashers and remove the setscrews, packers and shims

securing the bevel pinion housing. At this point the bevel pinion housing should be

supported by a second pair of hands, strapped or supported in some other manner to

prevent it dropping down sharply and causing damage to the casting, it will otherwise

only be secured by the loose fitting retaining plate and sprocket.

Remove the nuts and washer off the two bolts retaining the bevel pinion housing

adjusting plate. Using a soft faced hammer knock the bevel pinion shaft through the

sprocket until it is possible to remove the sprocket. Remove the bolts through the

retaining plate and lift the bevel pinion housing out of the trunnion.

Summary of Contents for 200TM

Page 3: ...WORKSHOP MANUAL 200TM SECTION 1 INTRODUCTION...

Page 6: ...WORKSHOP MANUAL 200TM SECTION 2 REPAIR SERVICE PROCEDURES...

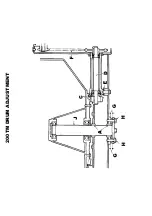

Page 12: ...200TM DRUM ADJUSTMENT...

Page 42: ...WORKSHOP MANUAL 200TM SECTION 3 GENERAL ARRANGEMENT DIMENSIONS...

Page 43: ...GENERAL ARRANGEMENT...

Page 44: ...DIMENSIONS...

Page 45: ...WORKSHOP MANUAL 200TM SECTION 4 SERVICE SCHEDULES LUBRICATION DIAGRAM...

Page 48: ...LUBRICATION POINTS...

Page 49: ...LUBRICANTS...

Page 50: ...WORKSHOP MANUAL 200TM SECTION 5 HYDRAULIC CIRCUIT DIAGRAMS...

Page 51: ...200TM LATER BASIC HYDRAULIC CIRCUIT...

Page 52: ...200TM LATER DRAGLINE BATCHWEIGER HYDRAULIC CIRCUIT...

Page 53: ...WORKSHOP MANUAL 200TM SECTION 6 WIRING DIAGRAMS...

Page 59: ...Hourmeter lamp dwg 04 03 02 12 50 36 Scaled to fit...

Page 60: ...Hourmeter no lamp dwg 04 03 02 12 53 33 Scaled to fit...

Page 62: ...WORKSHOP MANUAL 200TM SECTION 7 NOISE LEVELS...

Page 64: ...WORKSHOP MANUAL 200TM SECTION 8 SPECIAL TOOLS...

Page 65: ...200TM PUNCH VALVE SEAT 200TM SPECIAL TOOL V2003698 CASE HARDEN TO 45 50 ROCKWELL...

Page 66: ...200TM DRUM BLADE DRILLING GUIDE SPECIAL TOOL 200TM 513360100...

Page 67: ...200TM SPECIAL TOOLS...

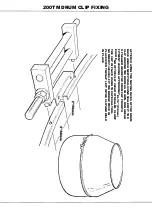

Page 68: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 69: ...WORKSHOP MANUAL 200TM SECTION 9 HYDRAULIC CONTROL VALVE SERVICE MANUAL...

Page 70: ...PAGE INTENTIONALLY BLANK...

Page 71: ...WORKSHOP MANUAL 200TM SECTION 10 PARTS LISTINGS...

Page 73: ...200TM MAINFRAME AXLES AND STABILISERS...

Page 90: ...200TM 415 VOLT START STOP SWITCH STAR DELTA...

Page 92: ...200TM 415 VOLT START STOP SWITCH DIRECT ON LINE...

Page 98: ...200TM HOPPER...

Page 110: ...200TM WATER TANK FIT SPECIAL WASHER V2004220 BETWEEN ITEMS 11 12...

Page 114: ...200TM DYNAMO AND MOUNTING LISTER PETTER TS1 HS...

Page 118: ...200TM DRAGLINE ASSEMBLY...

Page 120: ...200TM DRAGLINE ASSEMBLY...

Page 124: ...200TM DRAGLINE SHOVEL...

Page 126: ...200TM DRAGLINE FEEDAPRON...

Page 130: ...200TM LISTER PETTER TS1 ELECTRIC START...

Page 132: ...200TM DECALS AND LOGOS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22...

Page 134: ...200TM DECALS AND LOGOS 23 24 25 26 27 28 29...

Page 135: ...200TM SPECIAL TOOLS...

Page 136: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 137: ...WORKSHOP MANUAL 200TM SECTION 11 BATCHWEIGHER MAINTENANCE INSTRUCTIONS...

Page 138: ...MAINTENANCE INSTRUCTIONS HYDRAULIC WEIGHING UNITS WWW WINGET CO UK...

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 146: ......

Page 147: ......