WORKSHOP MANUAL

Winget Mechanically Fed Mixers

Models: 200TM

From 1998

Replace the clip and thimble and connect to the shovel ring. Slot the cable mast into

its sleeve on the R/H jib leg Unwind the electric cable from the shovel and connect

the two-pin plug into the socket below the mainframe. Loop the cable around the

crossbar at the base of the cable mast and then over the cleat at the top allowing

sufficient slack to allow the jib assembly to pivot upwards.

Assemble the two pulley blocks onto the cable. The first one is suspended from the

top of the cable mast, while the second hangs free between the first pulley and the

cleat on the cable mast (see the illustration in the operator’s handbook). The cable is

tensioned by means of a weight added to the free hanging pulley block.

Ensure the stabiliser legs are attached and securely chocked to prevent the mixer

toppling over and using the lifting equipment raise the jib assembly until the two tie

bars can be attached, tighten all the retaining nuts and bolts.

Connect the winch motor hoses, ensuring they are connected to the correct ports and

cable tie them neatly to the jib leg.

Start the engine or electric motor and move the hanging wire rope out of the path of

the hopper and fully raise the hopper checking it clears the top beam and pulleys.

Operate the dragline, check for hydraulic oil leaks and correct operation,

Lower the hopper and stop the engine.

Dragline Shovel

The handle assembly is attached to the shovel body via split pins and can be

replaced if worn or damaged. The grips are replaceable and simply push on.

The dragline operating switch is secured to the R/H handle using a simple clamp and

when if replacing reference should be made to the wiring diagrams to ensure it is

correctly connected.

Dragline Jib Dismantling

Also refer to the operators handbook

Attach suitable lifting equipment and take the weight of the jib, detach the tie bars,

lower the jib assembly and support in a horizontal position.

Unscrew the “D” link securing the shovel to the wire rope and remove one of the

pulleys from the double pulley allowing the rope to come free. Rebuild the pulley,

using a cable tie secure the end of the wire rope to the jib by the winch motor. Start

the engine, plug in the shovel and operate the switch to carefully rewind excess wire

rope back onto the rope drum. Stop the engine disconnect the hydraulic hoses at the

winch motor plugging both the hoses and the motor adapters to prevent the ingress

of dirt etc.

Summary of Contents for 200TM

Page 3: ...WORKSHOP MANUAL 200TM SECTION 1 INTRODUCTION...

Page 6: ...WORKSHOP MANUAL 200TM SECTION 2 REPAIR SERVICE PROCEDURES...

Page 12: ...200TM DRUM ADJUSTMENT...

Page 42: ...WORKSHOP MANUAL 200TM SECTION 3 GENERAL ARRANGEMENT DIMENSIONS...

Page 43: ...GENERAL ARRANGEMENT...

Page 44: ...DIMENSIONS...

Page 45: ...WORKSHOP MANUAL 200TM SECTION 4 SERVICE SCHEDULES LUBRICATION DIAGRAM...

Page 48: ...LUBRICATION POINTS...

Page 49: ...LUBRICANTS...

Page 50: ...WORKSHOP MANUAL 200TM SECTION 5 HYDRAULIC CIRCUIT DIAGRAMS...

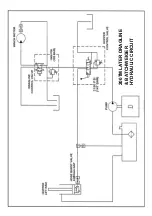

Page 51: ...200TM LATER BASIC HYDRAULIC CIRCUIT...

Page 52: ...200TM LATER DRAGLINE BATCHWEIGER HYDRAULIC CIRCUIT...

Page 53: ...WORKSHOP MANUAL 200TM SECTION 6 WIRING DIAGRAMS...

Page 59: ...Hourmeter lamp dwg 04 03 02 12 50 36 Scaled to fit...

Page 60: ...Hourmeter no lamp dwg 04 03 02 12 53 33 Scaled to fit...

Page 62: ...WORKSHOP MANUAL 200TM SECTION 7 NOISE LEVELS...

Page 64: ...WORKSHOP MANUAL 200TM SECTION 8 SPECIAL TOOLS...

Page 65: ...200TM PUNCH VALVE SEAT 200TM SPECIAL TOOL V2003698 CASE HARDEN TO 45 50 ROCKWELL...

Page 66: ...200TM DRUM BLADE DRILLING GUIDE SPECIAL TOOL 200TM 513360100...

Page 67: ...200TM SPECIAL TOOLS...

Page 68: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 69: ...WORKSHOP MANUAL 200TM SECTION 9 HYDRAULIC CONTROL VALVE SERVICE MANUAL...

Page 70: ...PAGE INTENTIONALLY BLANK...

Page 71: ...WORKSHOP MANUAL 200TM SECTION 10 PARTS LISTINGS...

Page 73: ...200TM MAINFRAME AXLES AND STABILISERS...

Page 90: ...200TM 415 VOLT START STOP SWITCH STAR DELTA...

Page 92: ...200TM 415 VOLT START STOP SWITCH DIRECT ON LINE...

Page 98: ...200TM HOPPER...

Page 110: ...200TM WATER TANK FIT SPECIAL WASHER V2004220 BETWEEN ITEMS 11 12...

Page 114: ...200TM DYNAMO AND MOUNTING LISTER PETTER TS1 HS...

Page 118: ...200TM DRAGLINE ASSEMBLY...

Page 120: ...200TM DRAGLINE ASSEMBLY...

Page 124: ...200TM DRAGLINE SHOVEL...

Page 126: ...200TM DRAGLINE FEEDAPRON...

Page 130: ...200TM LISTER PETTER TS1 ELECTRIC START...

Page 132: ...200TM DECALS AND LOGOS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22...

Page 134: ...200TM DECALS AND LOGOS 23 24 25 26 27 28 29...

Page 135: ...200TM SPECIAL TOOLS...

Page 136: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 137: ...WORKSHOP MANUAL 200TM SECTION 11 BATCHWEIGHER MAINTENANCE INSTRUCTIONS...

Page 138: ...MAINTENANCE INSTRUCTIONS HYDRAULIC WEIGHING UNITS WWW WINGET CO UK...

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 146: ......

Page 147: ......