WORKSHOP MANUAL

Winget Mechanically Fed Mixers

Models: 200TM

From 1998

Any hydraulic oil, which bypasses the piston seals, is ejected via the breather hole on

earlier machines, on later machines the return hose directs this hydraulic oil back to

the tank and is much more environmentally friendly.

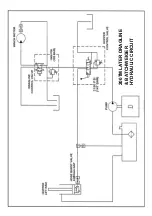

Hydraulic System Description – Batchweigher

The basic hydraulic system is modified when a batchweigher is fitted to include a

bleed valve, which is inserted into the circuit between the control valve and hydraulic

cylinder and adds an extra return line back to the tank.

The bleed valve is designed to ensure that when the hopper is fully lowered no

residual pressure remains in the circuit between the cylinder and control valve, which

could affect the batchweigher readings.

The bleed valve assembly contains a valve and spring and is ported to allow oil to

flow either to the hydraulic cylinder or to the hydraulic tank. (see the illustration)

On raising the hopper, hydraulic oil flows into the bleed valve body through the orifice

in the valve and out to the hopper ram. As the oil flows through the orifice under

pressure the valve is forced across the body compressing the return spring and

closing off the return port to the hydraulic tank.

On releasing the control lever to neutral during either the raising or lowering cycle,

hydraulic oil under pressure trapped in the line between the piston and control valve

spool holds the bleed valve against the return port seat. This prevents the oil

returning to the tank, thereby preventing the hopper from dropping.

Should the hopper continue to drop the seat/valve within the bleed valve assembly

possibly requires attention using the special tool. (see below)

If the system is operating correctly the hopper should remain stationary until the

control lever is operated.

On fully lowering the hopper, the reduction in pressure will allow the spring within the

valve body to push the bleed valve back across the body. This action opens the tank

return port allowing any residual oil/pressure trapped in the base of the cylinder to

return to the tank, thereby ensuring that the hopper is completely lowered, allowing

the striker to fully contact the loadcell ensuring the accuracy of the batchweigher

reading.

On assembling the bleed valve it is important that a good seat is formed within the

valve body using the special tool/punch part no. V2003698. The punch should be

inserted into the valve, shaped end first, and a seat formed by driving the punch

sharply down into the body using a soft faced hammer.

Summary of Contents for 200TM

Page 3: ...WORKSHOP MANUAL 200TM SECTION 1 INTRODUCTION...

Page 6: ...WORKSHOP MANUAL 200TM SECTION 2 REPAIR SERVICE PROCEDURES...

Page 12: ...200TM DRUM ADJUSTMENT...

Page 42: ...WORKSHOP MANUAL 200TM SECTION 3 GENERAL ARRANGEMENT DIMENSIONS...

Page 43: ...GENERAL ARRANGEMENT...

Page 44: ...DIMENSIONS...

Page 45: ...WORKSHOP MANUAL 200TM SECTION 4 SERVICE SCHEDULES LUBRICATION DIAGRAM...

Page 48: ...LUBRICATION POINTS...

Page 49: ...LUBRICANTS...

Page 50: ...WORKSHOP MANUAL 200TM SECTION 5 HYDRAULIC CIRCUIT DIAGRAMS...

Page 51: ...200TM LATER BASIC HYDRAULIC CIRCUIT...

Page 52: ...200TM LATER DRAGLINE BATCHWEIGER HYDRAULIC CIRCUIT...

Page 53: ...WORKSHOP MANUAL 200TM SECTION 6 WIRING DIAGRAMS...

Page 59: ...Hourmeter lamp dwg 04 03 02 12 50 36 Scaled to fit...

Page 60: ...Hourmeter no lamp dwg 04 03 02 12 53 33 Scaled to fit...

Page 62: ...WORKSHOP MANUAL 200TM SECTION 7 NOISE LEVELS...

Page 64: ...WORKSHOP MANUAL 200TM SECTION 8 SPECIAL TOOLS...

Page 65: ...200TM PUNCH VALVE SEAT 200TM SPECIAL TOOL V2003698 CASE HARDEN TO 45 50 ROCKWELL...

Page 66: ...200TM DRUM BLADE DRILLING GUIDE SPECIAL TOOL 200TM 513360100...

Page 67: ...200TM SPECIAL TOOLS...

Page 68: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 69: ...WORKSHOP MANUAL 200TM SECTION 9 HYDRAULIC CONTROL VALVE SERVICE MANUAL...

Page 70: ...PAGE INTENTIONALLY BLANK...

Page 71: ...WORKSHOP MANUAL 200TM SECTION 10 PARTS LISTINGS...

Page 73: ...200TM MAINFRAME AXLES AND STABILISERS...

Page 90: ...200TM 415 VOLT START STOP SWITCH STAR DELTA...

Page 92: ...200TM 415 VOLT START STOP SWITCH DIRECT ON LINE...

Page 98: ...200TM HOPPER...

Page 110: ...200TM WATER TANK FIT SPECIAL WASHER V2004220 BETWEEN ITEMS 11 12...

Page 114: ...200TM DYNAMO AND MOUNTING LISTER PETTER TS1 HS...

Page 118: ...200TM DRAGLINE ASSEMBLY...

Page 120: ...200TM DRAGLINE ASSEMBLY...

Page 124: ...200TM DRAGLINE SHOVEL...

Page 126: ...200TM DRAGLINE FEEDAPRON...

Page 130: ...200TM LISTER PETTER TS1 ELECTRIC START...

Page 132: ...200TM DECALS AND LOGOS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22...

Page 134: ...200TM DECALS AND LOGOS 23 24 25 26 27 28 29...

Page 135: ...200TM SPECIAL TOOLS...

Page 136: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 137: ...WORKSHOP MANUAL 200TM SECTION 11 BATCHWEIGHER MAINTENANCE INSTRUCTIONS...

Page 138: ...MAINTENANCE INSTRUCTIONS HYDRAULIC WEIGHING UNITS WWW WINGET CO UK...

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 146: ......

Page 147: ......