WORKSHOP MANUAL

Winget Mechanically Fed Mixers

Models: 200TM

From 1998

Drawbar-Standard

The standard drawbar is attached to the front axle via two bolts, flat washers and binx

nuts, to remove simply undo and remove the bolts and lift the drawbar clear. Reverse

the procedure to refit.

Drum Removal

Attach suitable lifting equipment through the Drum Blades. Knock back the tabs on

the tabwasher securing the Drum Shaft setscrews. Remove the setscrews and

washers securing the Shaft and Flange. With the Drum Mouth upright lift the Drum

assembly clear of the Trunnion. It may be necessary to rock the Trunnion via the

Tiltwheel to free the Drum Shaft.

In exceptional circumstances it may be necessary to use a Two-Leg Puller/Pusher

Tool to assist in pushing the Drum Shaft through the Trunnion. When using such

tools follow the manufacturers instructions.

Replacement of Drum Shaft, Bevel Gear and Bearings

Remove the drum as described previously and turn upside down so that the

assembly stands on the open mouth of the drum. Before removing the bevel gear

from the drum base use suitably sized circlip pliers and remove the large circlip

retaining the lower shaft bearing into the gear.

Remove the setscrews securing the bevel gear and shaft assembly to the drum base,

use two of the setscrews as jacking as screws utilising the threaded holes in the

bevel gear and jack the assembly out of the base.

With the assistance of suitable lifting equipment lift the assembly onto a suitable

supporting surface and using a soft faced hammer or mallet knock the shaft back

through the bevel gear. Support the shaft in a suitable soft jawed vice and remove

the smaller circlip from the end of the shaft retaining the upper drum bearing, using a

suitable drift or puller remove both bearings from the shaft. Clean all the components.

Before fitting new bearings carefully remove the seals from the bearings and pack

the bearings with good quality grease, refit the seals, do not completely fill the

bearings with grease leave some room for expansion as the grease warms up in

service.

Fit the new bearings to the shaft and retain the upper smaller bearing using a new

circlip. Clean out the drum centre shaft housing and smear a little anti-seize

compound round the circumference of the upper bearing seat within the housing.

Summary of Contents for 200TM

Page 3: ...WORKSHOP MANUAL 200TM SECTION 1 INTRODUCTION...

Page 6: ...WORKSHOP MANUAL 200TM SECTION 2 REPAIR SERVICE PROCEDURES...

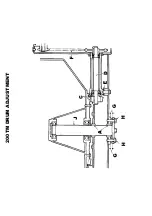

Page 12: ...200TM DRUM ADJUSTMENT...

Page 42: ...WORKSHOP MANUAL 200TM SECTION 3 GENERAL ARRANGEMENT DIMENSIONS...

Page 43: ...GENERAL ARRANGEMENT...

Page 44: ...DIMENSIONS...

Page 45: ...WORKSHOP MANUAL 200TM SECTION 4 SERVICE SCHEDULES LUBRICATION DIAGRAM...

Page 48: ...LUBRICATION POINTS...

Page 49: ...LUBRICANTS...

Page 50: ...WORKSHOP MANUAL 200TM SECTION 5 HYDRAULIC CIRCUIT DIAGRAMS...

Page 51: ...200TM LATER BASIC HYDRAULIC CIRCUIT...

Page 52: ...200TM LATER DRAGLINE BATCHWEIGER HYDRAULIC CIRCUIT...

Page 53: ...WORKSHOP MANUAL 200TM SECTION 6 WIRING DIAGRAMS...

Page 59: ...Hourmeter lamp dwg 04 03 02 12 50 36 Scaled to fit...

Page 60: ...Hourmeter no lamp dwg 04 03 02 12 53 33 Scaled to fit...

Page 62: ...WORKSHOP MANUAL 200TM SECTION 7 NOISE LEVELS...

Page 64: ...WORKSHOP MANUAL 200TM SECTION 8 SPECIAL TOOLS...

Page 65: ...200TM PUNCH VALVE SEAT 200TM SPECIAL TOOL V2003698 CASE HARDEN TO 45 50 ROCKWELL...

Page 66: ...200TM DRUM BLADE DRILLING GUIDE SPECIAL TOOL 200TM 513360100...

Page 67: ...200TM SPECIAL TOOLS...

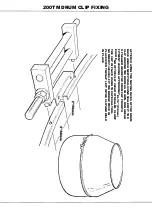

Page 68: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 69: ...WORKSHOP MANUAL 200TM SECTION 9 HYDRAULIC CONTROL VALVE SERVICE MANUAL...

Page 70: ...PAGE INTENTIONALLY BLANK...

Page 71: ...WORKSHOP MANUAL 200TM SECTION 10 PARTS LISTINGS...

Page 73: ...200TM MAINFRAME AXLES AND STABILISERS...

Page 90: ...200TM 415 VOLT START STOP SWITCH STAR DELTA...

Page 92: ...200TM 415 VOLT START STOP SWITCH DIRECT ON LINE...

Page 98: ...200TM HOPPER...

Page 110: ...200TM WATER TANK FIT SPECIAL WASHER V2004220 BETWEEN ITEMS 11 12...

Page 114: ...200TM DYNAMO AND MOUNTING LISTER PETTER TS1 HS...

Page 118: ...200TM DRAGLINE ASSEMBLY...

Page 120: ...200TM DRAGLINE ASSEMBLY...

Page 124: ...200TM DRAGLINE SHOVEL...

Page 126: ...200TM DRAGLINE FEEDAPRON...

Page 130: ...200TM LISTER PETTER TS1 ELECTRIC START...

Page 132: ...200TM DECALS AND LOGOS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22...

Page 134: ...200TM DECALS AND LOGOS 23 24 25 26 27 28 29...

Page 135: ...200TM SPECIAL TOOLS...

Page 136: ...1 513204000 CLAMP DRUM CLIP 1 2 V2003698 PUNCH BLEED VALVE SEAT 1 200TM SPECIAL TOOLS...

Page 137: ...WORKSHOP MANUAL 200TM SECTION 11 BATCHWEIGHER MAINTENANCE INSTRUCTIONS...

Page 138: ...MAINTENANCE INSTRUCTIONS HYDRAULIC WEIGHING UNITS WWW WINGET CO UK...

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 146: ......

Page 147: ......