OPERATION (‘HL’ Model) 12A

Never

commence work until the daily service checks have been

carried out.

Only

tip or discharge the skip or raise the scissors on level ground.

The hydraulic system control valve and operating levers are mounted

on top of the hydraulic tank on the left-hand side of the machine.

The inner lever controls the scissor operation whilst the outer lever

controls the skip tipping functions, the function of each lever is

indicated on the decal on the rear of the valve mounting plate.

The operating levers have three positions, forwards for ‘Scissor Lift’

or ‘Skip Tip’, centre for ‘Neutral’ or ‘Hold’ and rearwards for ‘Scissor

Lower’ or ‘Skip Return’.

The hydraulics will not operate until the engine is running, although

it is possible to lower a raised skip or scissors without engine power

by moving the operating levers to the ‘Dump’ or ‘Lower’ positions.

For this reason the machine should not be left unattended with either

the skip or scissors raised. Refer to the Honda HP500H Operators

Handbook for instructions on starting the engine.

With the engine running and the engine speed set to fast idle, refer to

the decal on the rear of the valve mounting plate and identify the

lever controlling the function required, slowly push the lever

forwards. The rate of oil delivered to the skip tipping or scissor ram

and therefore the speed at which the skip tips or the scissors lift is

proportional both to the distance the lever is moved and the speed at

which the engine is set.

Holding the lever forwards until the skip or scissors reaches the

maximum travel of the ram will cause the relief valve located in the

control valve to ‘blow off’ allowing the oil to return to tank. Do not

hold the lever forward when the ‘relief valve’ blows, this will cause

the hydraulic oil temperature to increase and may cause damage to

components. Once the ram reaches the end of its travel release the

lever to the neutral or hold position.

Releasing the operating lever will allow it to automatically return to

neutral position and movement of the skip or scissors will stop, even

if the ram has not reached the full extent of its travel, or the skip is

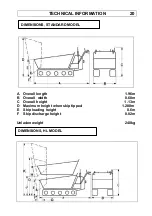

Summary of Contents for TD500

Page 2: ......

Page 4: ......

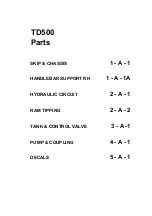

Page 29: ...PARTS INFORMATION 23 TD500 TD500HL PARTS SECTION ...

Page 30: ......

Page 32: ......

Page 33: ...1 A 1 TD500 Dumper ...

Page 35: ...1 A 1A TD500 Dumper ...

Page 37: ...2 A 1 TD500 Dumper ...

Page 39: ...2 A 2 TD500 Dumper ...

Page 41: ...3 A 1 TD500 Dumper ...

Page 43: ...4 A 1 TD500 Dumper ...

Page 45: ...5 A 1 TD500 Dumper ...

Page 48: ......

Page 49: ...1 A 1 TD500HL Dumper ...

Page 51: ...1 A 1A TD500HL Dumper ...

Page 53: ...1 A 2 TD500HL Dumper ...

Page 55: ...2 A 1 TD500HL Dumper ...

Page 57: ...2 B 1 TD500HL Dumper ...

Page 59: ...2 C 1 TD500HL Dumper ...

Page 61: ...2 R 1 TD500HL Dumper ...

Page 63: ...3 A 1 TD500HL Dumper ...

Page 65: ...4 A 1 TD500HL Dumper ...

Page 67: ...4 A 2 TD500HL Dumper 5 6 ...