17

6.Installation and connection

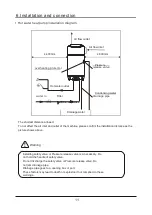

6. Electric wiring

Instruments should be installed in accordance with state wire installation rules.

At the bottom of the unit there are electric plugs for the user to connect the unit to the

power supply.

When the external circuits connecting with the unit, the circuit connection should be with

leakage protection device and power broker device.

If the power line is damaged, you must purchase a new one from the factory or a qualified

agent ,or other products with the same certificates.

7. Trial operation

1. The examine before trial operation

Check whether the water tank is full of water and the water pipes are installed well.

Examine the power supply distribution system and check whether the voltage is normal and

the earth wires and wiring connections are in good condition.

Examine the unit: When the unit is power on, observe whether the indicator light and the

temperature of the controller are working normally.

2. Test running

Starting the unit by the wire controller.

When the unit is operating, judge the unit whether is with abnormal sound by hearing, if so,

the unit should be stopped and examined at once.

Check the water temperature in the water tank to see whether it is normal.

It may need 5 ~ 15 hours for the unit to achieve the target temperature for the first time

depends on the water and ambient temperature.

Attention

Power lines shall be arranged in neat and reasonable way and in accordance with

state cord rules for installation.

Summary of Contents for WSW1-80L-WM

Page 1: ...SANITARY WATER WALL MOUNTED Operation Installation Manual ...

Page 27: ......

Page 28: ...CODE 20170424 0001 ...