3

Version

1.0

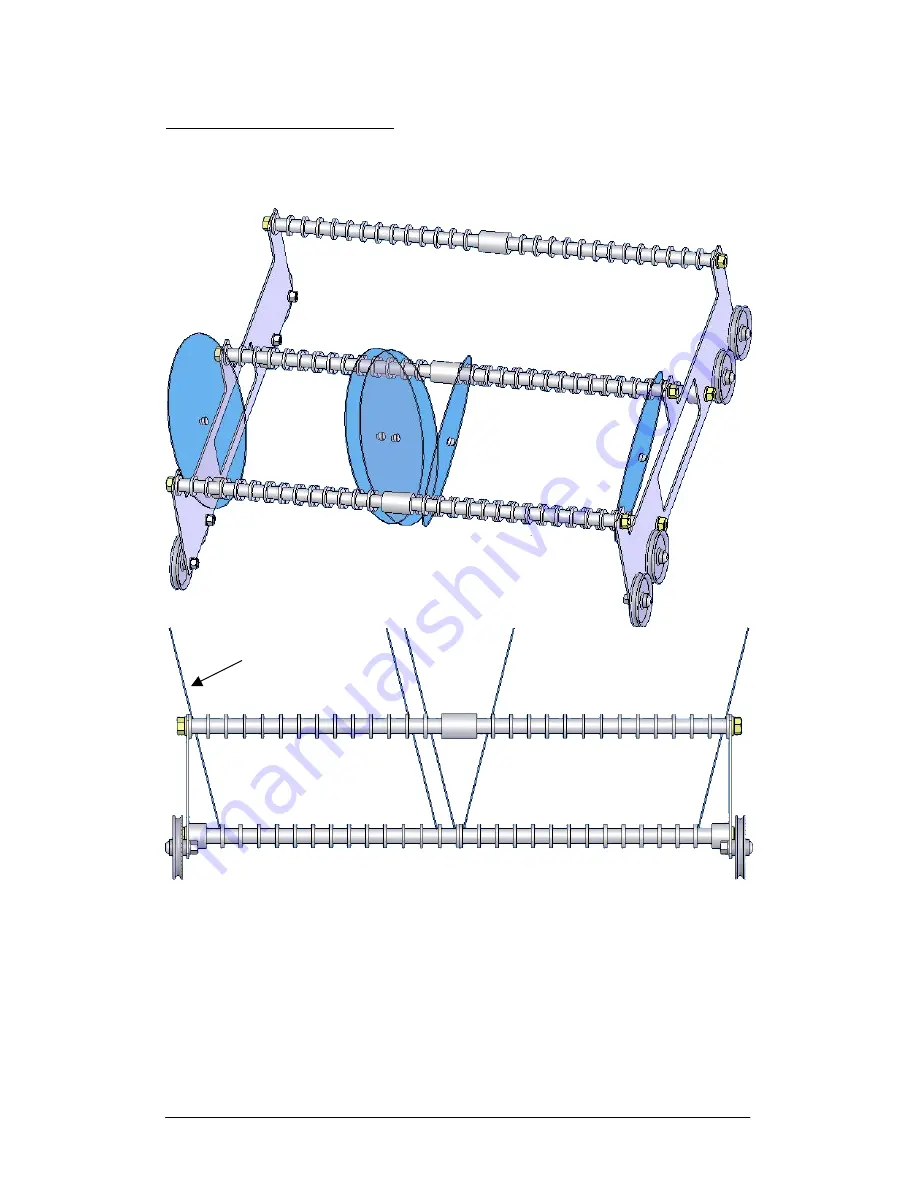

Loading the substrates

The substrates are loaded under a small angle with the recorded surface facing up.

Part of the washing process is the mechanical force the spraying water has when it hits

the glass substrates. Placing the substrates in a way where the spray bars can not spray

the water on the polluted surface will reduce the washing effect and might result in

particles remaining on the substrates surface.

Recorded surface

Summary of Contents for 4P GDR

Page 1: ...Operating manual 4P GDR ...