5.2.4

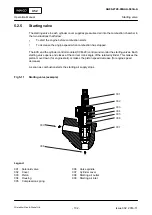

Direct controlled injection valve

The injection valves are installed in the cylinder cover of each cylinder. The injection valves spray

the fuel into the combustion chamber. The ECS controls the solenoid valve and thus the pilot valve

of the injection valves. This controls the timing and the quantity of the injected fuel related to the

power.

When the pilot valve opens, the high pressure of the supplied fuel opens the needle in the nozzle

body (005,

). This lets the fuel flow through the holes in the nozzle tip (006) into the

combustion chamber as a spray. When the pilot valve closes, the fuel pressure closes the needle

again.

A small quantity of control fuel flows from the pressurized annular groove (004) through the return

pipe to the plant fuel system.

Fuel leakage with a small quantity of lubricating oil flows from the depressurized annular groove

(003) through drain pipes to the plant overflow tank.

Oil from the main oil supply lubricates the control element in the injection valves. If for the engine

it is necessary to stop the oil flow after engine stop, a solenoid valve is installed in the oil supply

pipe. Thus this solenoid valve closes, when the engine has stopped. This prevents that the

temperature of the remaining fuel in the injection valves decreases too much.

Fig 5-10

Injection valve (example)

001 002 003

004

006

005

007

009

008

Legend

001

Annular groove - oil return

006

Nozzle tip

002

Annular groove - oil inlet

007

Electrical cable to control valve

003

Annular groove - fuel leakage

008

Fuel inlet

004

Annular groove - control fuel return

009

Valve bush

005

Nozzle body

X52

AA00-2722-00AAA-043A-A

Operation Manual

Direct controlled injection valve

Winterthur Gas & Diesel Ltd.

- 130 -

Issue 002 2018-11