6.3

Local display unit (LDU-20) - general

6.3.1

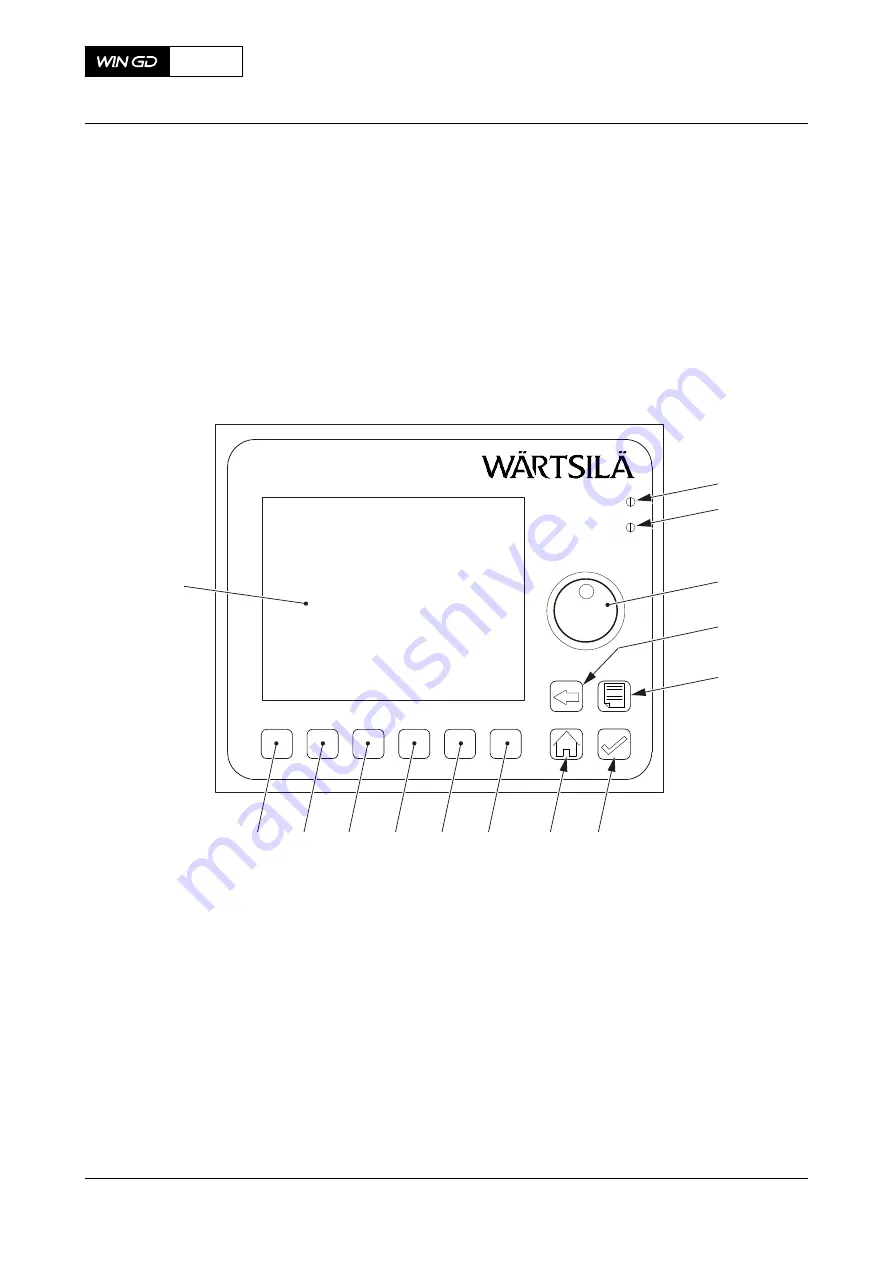

Local display unit (LDU-20)

) is a multi-purpose module that has an LCD color display (009), ten multi-

function buttons (004 to 008) and a rotary button (003).

There are two LDU-20. One LDU-20 is installed in the local control panel (refer to

). The other LDU-20 is installed in the engine control room.

Fig 6-5

LDU-20 - overview

POWER

STATUS

PUSH SELECT

00209

001

009

008

008

008

008

008

008

007

006

002

003

005

004

Legend

001

Power LED

006

CHECK button (used to accept the action or

enter data)

002

Status LED

007

HOME button (push to show the main page)

003

Rotary button (16 steps in one turn, push to

select)

008

Multi-function buttons (function is shown on

the display)

004

BACK button (used to cancel the action or

delete data)

009

Color display

005

Failure LIST button (push to show the failure

list)

X52

AA00-0000-00AAA-043H-A

Operation Manual

Local display unit (LDU-20) - general

Winterthur Gas & Diesel Ltd.

- 216 -

Issue 002 2018-11