3.3.3

Controllable pitch propeller (CPP)

3.3.3.1

Load ranges

After engine start, the engine operates at an idle speed of up to 70% of the rated engine speed

with zero pitch. From idle speed, the propeller pitch must be increased with constant engine speed

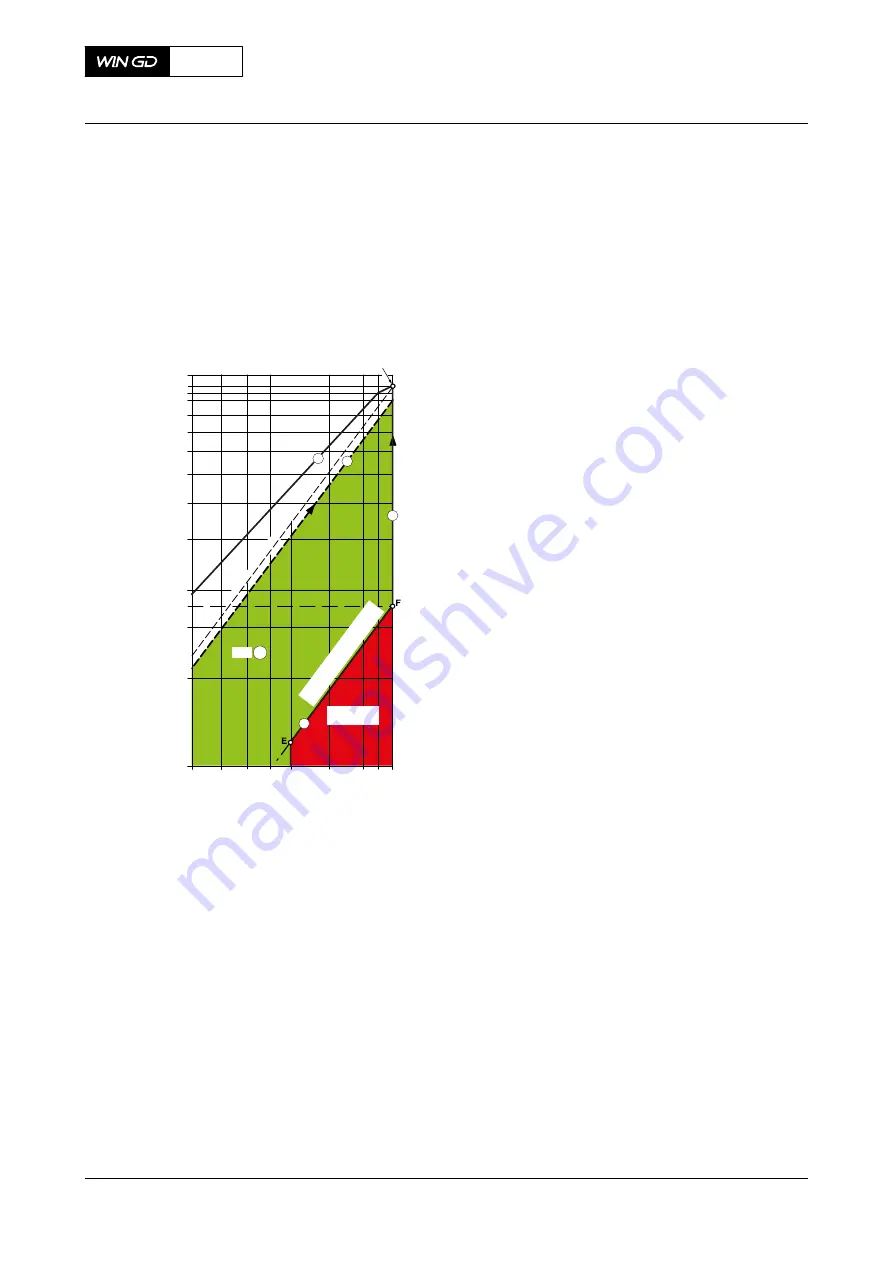

to the minimum at point E, the intersection with Line 9 (see

Fig 3-6

Schematic diagram - Relation Speed/ Power (CPP)

Engine speed [% Rx]

Engine power [% Rx]

CMCR [Rx]

5

10

15

20

30

17

40

50

60

60

65

70

80

90

100

70

80

90

100

110

nominal propeller characteristic

55

50

7

A

Field

prohibited

operation area

zero pitch propeller characteristic

(zero thrust)

5

6

8

00116

•

Line 9 is the bottom load limit between 70% and 100% speed, with a pitch position that at

100% speed, is the minimum power at point F is 37%. The formula shown in paragraph 1

is used for this calculation.

•

Along Line 8, the power increase from 37% (point F) to 100% power (CMCR) at 100% speed

is the constant speed mode for the shaft generator operation.

•

Line 5 is the top load limit and relates to the permitted torque limit.

•

The area between 70% and 100% speed and between Line 5 and Line 9 shows the area

that an engine with a CPP must be operated.

•

Line 7 shows a typical combinator curve for variable speed mode.

Maneuvering at maximum speed with low or zero pitch is not permitted. Thus, installations with

main engine-driven generators must have a frequency converter when electrical power is to be

supplied (eg to thrusters) at constant frequency during maneuvering. As an alternative, power from

auxiliary engines can be used for this purpose.

For test purposes, the engine can be operated at rated speed and low load during a one-time

period of 15 minutes on the testbed (eg NO

x

measurements) and 30 minutes during dock trials (eg

X52

AA00-0000-00AAA-042B-A

Operation Manual

The relation between engine and propeller

Winterthur Gas & Diesel Ltd.

- 65 -

Issue 002 2018-11