Maintenance

2751

−

3/A1

Winterthur Gas & Diesel Ltd.

Exhaust Valve

Valve Seat

−

Replace / Grind

Tools:

1 Feeler gauge

94122

1 Valve seat fitting and dismantling device

94261

1 Gauge

94279

1 Valve grinding device

94291

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.

General

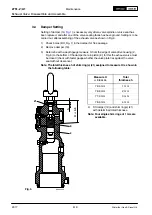

Valve seats of which the seat surfaces are badly damaged, or on which the wear limit

has been reached through frequent grinding, must be replaced.

The most advantageous position for replacing the valve seat is to bring the valve cage in

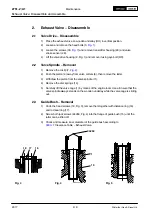

a vertical position as shown in Fig. 1.

Note: When the valve seat must be removed with the valve cage in the inverted

position, it must be suspended on the engine room crane slightly above a

wooden underlay. Device 94261 can then be attached from below and the

valve seat carefully withdrawn until it drops caused by its own weight .

Therefore, the valve seat must be properly secured with additional wooden

underlays. The distance to the wooden underlay is to be kept as small as

possible to avoid any accidents or damage.

2.

Valve Seat

−

Removal

1) Fit both pairs of ring halves of the valve seat fitting and dismantling device 94261

into the groove on the circumference of the valve cage 2 and valve seat 1

respectively.

2) With the aid of the three jack screws of the valve seat fitting and dismantling device,

the valve seat can be pressed out of its seating in the valve cage.

D

Should a valve seat be removed for any reason, it must be reground by means of

valve grinding device 94291 before refitting.

WCH00894

94261

2

1

Fig. 1

2017

Summary of Contents for X35-B

Page 12: ...Intentionally blank ...

Page 14: ...Intentionally blank ...

Page 16: ...Intentionally blank ...

Page 34: ...Intentionally blank ...

Page 58: ...Intentionally blank ...

Page 60: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 2 6 WCH03791 2017 ...

Page 61: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 3 6 WCH03791 2017 ...

Page 62: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 4 6 WCH03791 2017 ...

Page 63: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 5 6 WCH03791 2017 ...

Page 64: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 6 6 WCH03791 2017 ...

Page 68: ...Intentionally blank ...

Page 72: ...Intentionally blank ...

Page 82: ...Intentionally blank ...

Page 85: ...Intentionally blank ...

Page 92: ...Intentionally blank ...

Page 96: ...Intentionally blank ...

Page 112: ...Intentionally blank ...

Page 120: ...Intentionally blank ...

Page 124: ...Intentionally blank ...

Page 138: ...Intentionally blank ...

Page 154: ...Intentionally blank ...

Page 168: ...Intentionally blank ...

Page 180: ...Intentionally blank ...

Page 182: ...Maintenance 2728 1 A1 Winterthur Gas Diesel Ltd 2 5 6 Lift housing from the valve spindle 4 ...

Page 186: ...Intentionally blank ...

Page 190: ......

Page 204: ...Intentionally blank ...

Page 211: ...Intentionally blank ...

Page 216: ...Intentionally blank ...

Page 224: ...Intentionally blank ...

Page 228: ......

Page 229: ...Intentionally blank ...

Page 264: ...Intentionally blank ...

Page 270: ...Intentionally blank ...

Page 280: ...Intentionally blank ...

Page 294: ...Intentionally blank ...

Page 298: ...Intentionally blank ...

Page 302: ...Intentionally blank ...

Page 318: ...Intentionally blank ...

Page 328: ...Intentionally blank ...

Page 344: ...Intentionally blank ...

Page 368: ...Intentionally blank ...

Page 374: ...Intentionally blank ...

Page 380: ...Intentionally blank ...

Page 396: ...Intentionally blank ...

Page 407: ...Intentionally blank ...

Page 426: ...Intentionally blank ...

Page 442: ...Intentionally blank ...

Page 444: ...Intentionally blank ...