17

INSTALLATION MANUAL

AIR HEATER TYPE DXC

6.2 Minimum firing time

The heater will always fire for a minimum of 1 minute, even

if the heat demand stops. This is to avoid a large amount of

start and stops.

NOTICE

The heater will try to ignite 2 times before it stops

and gives an error.

6.3 Summer ventilation

The fan can be set to run in the summer. Follow the

instructions in the user manual of the special Room

thermostat.

6.4 Overheating protection

The air heater's heat exchanger and flue system are both

protected from excessive temperatures.

6.4.1

Heat exchanger

An NTC sensor is located near (or on) the heat exchanger.

This sensor monitors the heat exchanger temperature.

If the heat exchanger becomes too hot, this sensor will

cause the heating process to stop. Depending on the

temperature, the air heater performs the following actions:

• Step 1: Power reduction (when possible).

• Step 2: Burner stop, followed by an automatic

restart when cooled down (display: E05 / E36).

• Step 3: Burner stop, followed by a Lock Out. A

manual reset is required. (display L15).

NOTICE

A manual reset can be done on the electronic

circuit board or remotely with the special Room

thermostat.

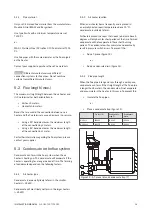

6.5 Flue passage check

The air heater is equipped with a pressure switch that

checks the passage of combustion air through the heat

exchanger. The pressure switch checks if there is sufficient

movement of combustion air through the heat exchanger.

If the pressure difference is too low, the air heater will stop.

Error L-14 will be shown on the display.

7 Commissioning the air heater

7.1 Adjusting the settings

Prior to packaging, the safety and functioning of each

air heater is checked in detail. It is also set to the right

combustion efficiency.

In general, the heater does not need to be adjusted after

installation. It is only necessary to perform a functional

check and to obtain a flue gas analysis and record it for

later reference.

CAUTION!

Use only calibrated instruments to adjust the

air heater.

CAUTION!

Never carelessly turn the adjuster screws.

NOTICE

Adjusting the control without a supporting flue

gas analysis voids the warranty.

Only adjust the burner pressures if they differ more than

0,5 mbar from its setting.

7.2 Commissioning the air heater

Once the unit is installed according to this manual, the unit

can be commissioned. To do so, follow these instructions:

1. Make sure the gas supply pipe is clean, gas tight

and free from air.

2. Switch on the electric supply with the maintenance

switch.

You are now able to observe the first start-up and become

familiar with the functioning of the heater.

NOTICE

If the gas line is not purged correctly, the heater

will attempt to start twice before going into a lock-out

condition. In this case, manual reset is necessary.

1. Instruct the end user of the about a safe use of the

air heater:

a. The presence of gas

b. The location of the manual gas valve