Instructions condensing Air heaters type XR version XR-GB-4001-a

Page 4/27

2.2.4 Protection from water, IP class

The heater is not waterproof. This means that it may not be exposed to rain, spry or dripping

water. The IP classification is IP00B

2.2.5 Protection against dust

The appliance is not designed for use in a very dusty environment. Dust may accumulate in the

heater and may cause a defect of the heater. This is also the case for the room-thermostat

2.2.6 Temperature

Do not install the heater in places where the temperature can rise above 35°C. At higher

temperatures the internal components will degrade much faster. This is not covered by the

guaranty.

2.2.7 Corrosive environment

The heater should not be installed in areas containing any corrosive or explosive vapours. It

should be prevented that chlorine or other corrosive containing vapours are sucked into the air

intake. These vapours will result in corrosion of the heat exchanger and a leakage of

condensate and flue gas. Defects caused by this are not covered by guaranty. Please consult

your supplier. This is also the case for the room-thermostat

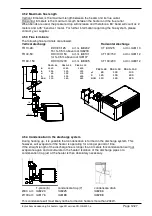

2.2.8 Installation distances

Keep sufficient distance between the heater and any obstruction, in connection with safety and

access for service and maintenance. Pay particular attention to any flammable materials.

Please take into account the possibility to open the door of the heater for the necessary service

and maintenance work . Make sure the air flow to and from the heater is free from obstacles

minimum 5 metres in front of the heater. Read the chapter “Installation” carefully.

Also take the clearance distances from the flue system into account.

2.2.9 Maintenance

For the safe and proper operation of the heater periodical maintenance is necessary. When the

heater is not serviced and cleaned in time, it could lead to damage to the heater or its

surroundings.

2.3 Guarantee

The guarantee becomes void when the air heaters are not installed and serviced in accordance

with this manual.