16

Always place a bracket on or near a bend or elbow piece,

except if the flue pipes before and after the elbow piece

are shorter than 0,25 m. In this case, fix the second

element after the elbow with a bracket.

Every flue discharge system needs to be secured with at

least one bracket. The first bracket needs to be within the

first 0,5 m of the air heater.

When installing a flue system inside a shaft, do the

following:

1. Check the components for possible damage or

blockage.

2. Check that the pipe is at the right slope (see

Requirements).

3. Mark the flue pipes and fresh air pipes to avoid

mixing them up.

4. Make sure that the pipes extend for at least 50 mm

when passing through a wall or other obstacle.

5. Fix the last element before entering the shaft in

place. If the last element is an elbow piece, the

next element must also be fixed in place.

6. Check if ventilation openings and inspection

hatches comply with national and local regulations.

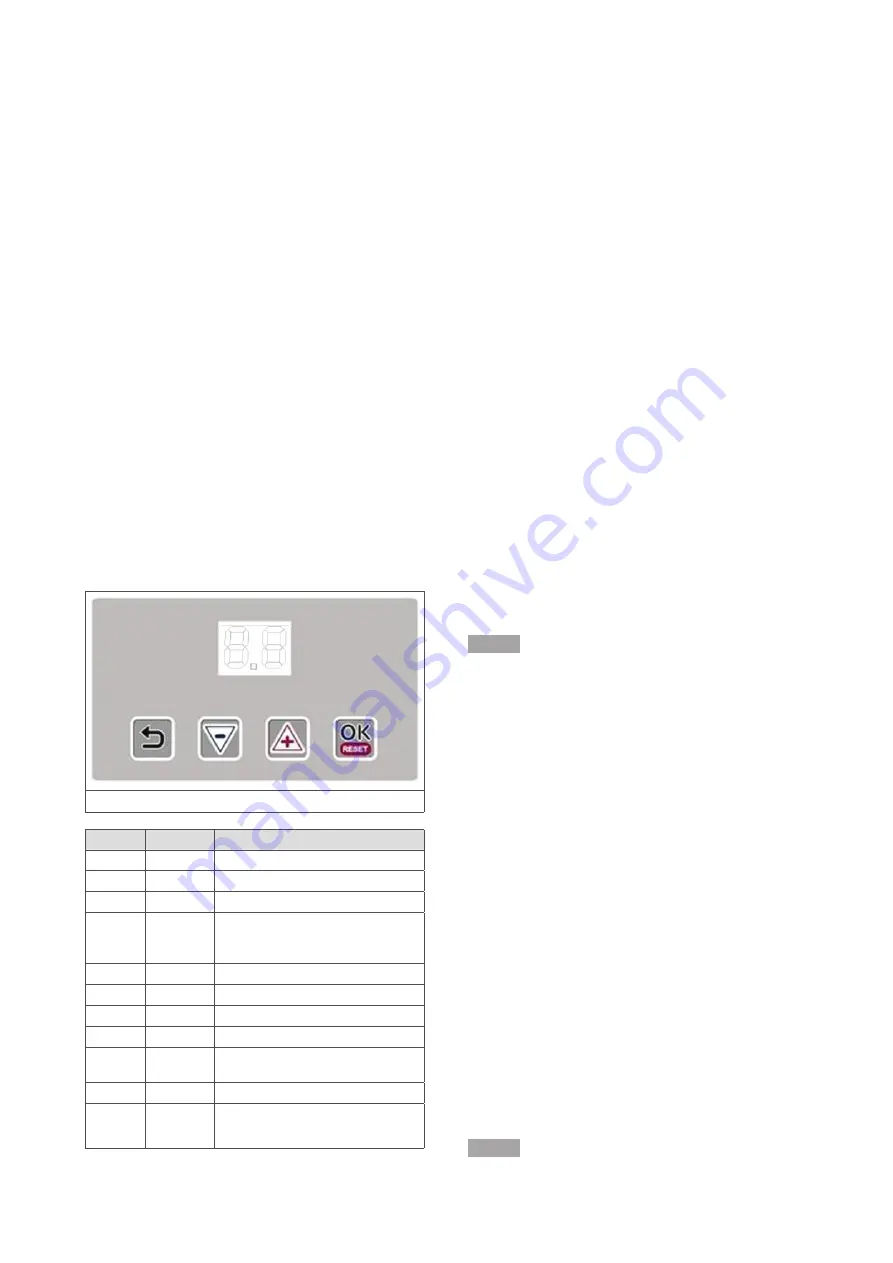

6 Operating the air heater

6.1 Burner cycle

The air heater’s display shows the current status of the

burner cycle (figure 20).

Figure 20 - Display of the air heater

Display

Status

Description

0

Stand-by

Waiting for heat demand.

1

Reset

Software reset.

3

Pre-check

Zero position check pressure switch.

4

Pre-purge

30 seconds of pre ventilation by the

combustion fan. The pressure switch is

checked.

5

Pre-ignition

Ignition without opening the gas valve.

6

Ignition

5 seconds of ignition. The gas valve opens.

7

Flame check The air heater checks if the flame is present.

8

Burn

The heater fires up and starts to modulate.

9

Minimum

Before the flame stops, the burner will

modulate to minimum power.

10

Burner off

The gas valve closes. The flame stops.

11

Post purge

Burner fan purges with fresh air.

System fan cools the heat exchanger.

6.2 Minimum firing time

The heater will always fire for a minimum of 4 minutes,

even if the heat demand stops. This is to avoid a large

amount of start and stops and to prevent condensate from

accumulating in the flue system.

NOTICE

The heater will try to ignite 2 times before it stops

and gives an error.

6.3 Delta-T-regulation

The air heater can function as a de-stratification fan. This

is called delta-T regulation and it is done via the room

thermostat, with a temperate measurement sensor that is

located on the air heater.

The system fan is activated when the temperature-

difference between the sensor on the heater (the delta-T

NTC sensor) and the sensor in the thermostat is bigger

than 8

o

C (standard factory setting). This procedure

ensures an even distribution of temperature throughout

the building, thus acting as a fully automatic de-

stratification fan.

6.3.1

Switch off delta-T-regulation

Delta-T regulation can be switched off when it is not

desired (e.g. when it causes discomfort). This can be

done in the

Settings

menu on the room thermostat. See

the user manual of the special Room thermostat for more

information.

NOTICE

Delta-T regulation is automatically switched

off when the delta-T sensor (sensor terminal J6) is

disconnected.