V1

9

Winton WTL15

6. SERVICING & MAINTENANCE

Lubrication & Maintenance

Lower the trailer to the ground and relieve pressure in trailer hydraulic lines prior to performing any

service or maintenance operations on the tractor or trailer. When checking hydraulic system oil level,

the tractor should be on the ground and the trailer emptied & fully retracted (all cylinders in retracted

position).

Check the tractor hydraulic system as outlined in the tractor operator’s manual.

Inspect hydraulic hoses, connections, control valve and cylinders for evidence of leakage regularly.

Grease all trailer pivot points daily (10 hours).

Other Maintenance

Oils: Ensure oil levels are checked and topped up when needed.

Cleaning: Ensure the machine is cleaned of mud and grass. Remove debris is from any moving parts.

Paintwork: Re-coat any damaged paintwork to prevent corrosion.

Wheels: Check the condition of all wheels and replace if any are broken or damaged.

Storage: Store the machine in a dry, level area with the hand brake applied. Chock the wheels and

support the frame if necessary.

The periods recommended are based on normal operating conditions. Severe or unusual conditions

may require more frequent maintenance.

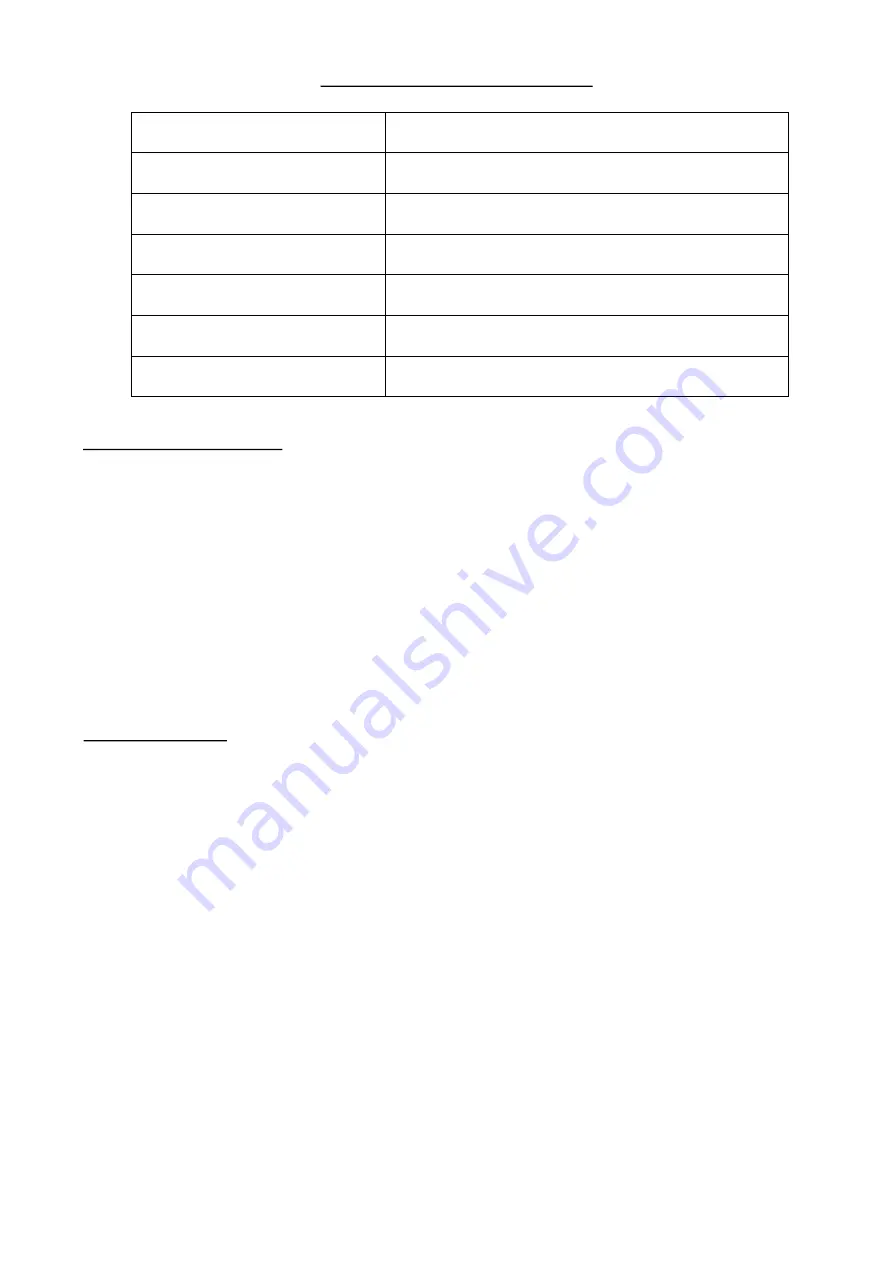

Grease Type

Multi-purpose lithium based grease

Pivot Points Grease Frequency

Check every 4-8 hours (top up if required)

Hydraulic Oil Type/Level

Check daily/10hrs (see tractor manual)

Hydraulic Oil Filter

See tractor manual for filter change

Trailer Tyre Pressure

Approx. 20-30psi (dependent on condition)

Tyre Pressure Check Frequency

Check weekly/50hrs which ever is first

Hydraulic connectors & RAM

Check daily/10hrs which ever is first

Summary of Contents for WTL Series

Page 18: ...V1 16 Winton WTL15 NOTES ...

Page 19: ...V1 17 Winton WTL15 ...

Page 20: ...www wintonmachinery co uk ...