V1

10

Winton WTL15

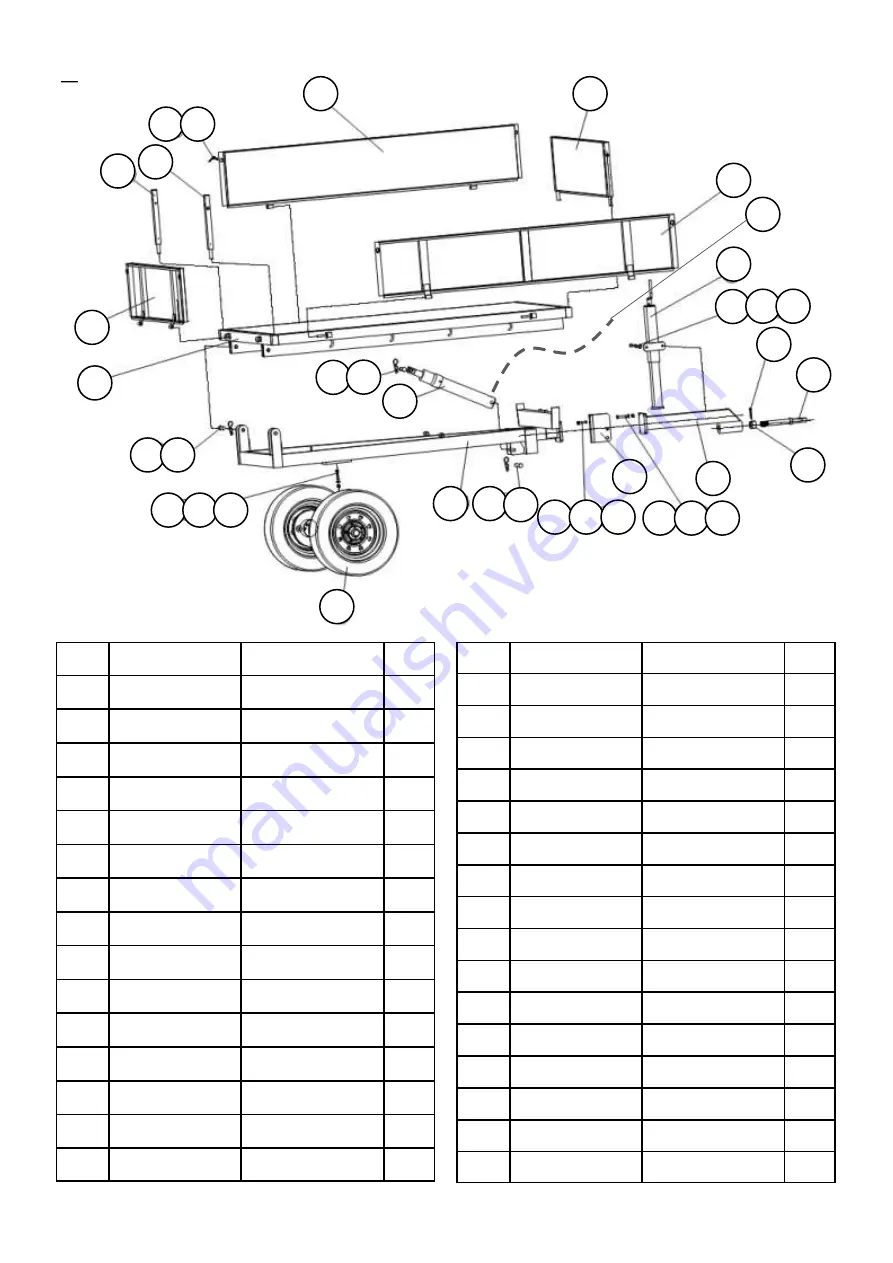

7. Parts Diagram/List 1

Dia

Part Number

Part Description

Qty

1

TR100.021

Bottom Panel

1

2

TR100.020

Rear Panel

1

3

TR100.022

Left Pillar

1

4

TR100.019

Right Pillar

1

5

TR100.017

Lock Mechanism

6

6

GB/T6170-00

Nut M8

6

7

TR100.023

Left Panel

1

8

TR100.016

Front Panel

1

9

TR100.018

Right Panel

1

10

TR100.002

Jockey Stand

1

11

GB/T5783-00

Bolt M12x40

2

12

GB/T93-87

Spring Washer

6

13

GB/T97.1-02

Plain Washer

10

14

GB/T91-00

Cotter Pin

1

15

TR100.101

Pin Hitch

1

Dia

Part Number

Part Description

Qty

16

GB/T6178-86

Nut M30

1

17

TR100.010

Drawbar

1

18

GB/T5782-00

Bolt M12x50

8

19

GB/T889.1-00

Locknut M12

8

20

TR100.012

Brake Fixing Plate

1

21

GB/T5783-00

Bolt M10x30

2

22

GB/T93-87

Spring Washer

2

23

GB/T97.1-02

Plain Washer

2

24

TR100.109

Cylinder Pin

1

25

TR100.107

R Clip

4

26

TR100.015

Chassis

1

27

TR100.014

Hydraulic Ram

1

28

TR100.108

Pin

1

29

TR100.041

Wheel

2

30

TR100.113

Pin

2

31

TLHOSE

Hydraulic Hose

1

1

2

3

4

5

6

7

8

9

10

11 12 13

14

15

16

17

18 19 13

20

21 22 23

24 25

26

27

28 25

29

30 25

18 19 13

31

Summary of Contents for WTL Series

Page 18: ...V1 16 Winton WTL15 NOTES ...

Page 19: ...V1 17 Winton WTL15 ...

Page 20: ...www wintonmachinery co uk ...