WireCrafters

Outside Slide Door

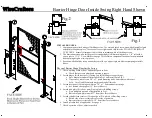

INSTALLER NOTES

1.

Doors wider than 5’ are made up of multiple door panels (see page 16), and use two pieces of track spliced at Splice Track Bracket (A).

2.

Component parts attach using self-drilling screws. Use variable speed screw gun with adjustable clutch or depth locating nose piece. Use care not to

over tighten and strip threads. DO NOT USE IMPACT TYPE GUNS. Securely clamp part in place before attaching with self drilling screws.

3.

Partition wall should be set up and anchored to floor. It is CRITICAL that posts are plumb and in line. Door opening should be square.

Outside Slide Door

1.

Check that door posts are anchored and plumb.

2.

Using a 3/8” x 3” bolt, install Splice Track Bracket (A) on face side of door post (B) opposite door receiver post (C). Note: if enclosure has ceiling

use a 3/8” x 1” bolt to attach bracket see Fig.1.

3.

Place two 4 wheel trolley trucks (F) into track (D). Using one 3/8” x 1” bolt, attach track bracket (G-1) to track.

a.

Check that trucks roll freely in track.

4.

Slide open end of track (D) into Splice Track Bracket (A). Using one 3/8” x 3” bolt, attach track bracket (G-1) to receiver post (C) see Fig 2.

5.

Invert Track Bracket (G-2) and attach to far end of Track (D) using one 3/8” x 1” bolt. If end of track aligns with post, do not invert track bracket.

a.

For doors wider than 5’

i.

Attach inverted bracket to far end of second track section.

ii.

Slide open end of second track section (D) into open end of Splice Track Bracket (A).

6.

Using one 3/8” x 1-1/2” bolt and two slide door shims (O), attach the inverted track bracket on the far end of Track (D) to the wire mesh panel.

a.

Per Fig. 3 place one flat slide door shim between the Track Bracket (G-2) and the mesh, and the other Slide Door Shim on the inside of the

mesh and fasten in place with one 3/8” x 1-1/2” bolt and hex nut. TRACK MUST BE LEVEL.

b.

Should Track Bracket (G-2) align with post, attach upright track bracket to post with 3/8” bolt.

7.

For doors wider than 5’ or taller than 8’, assemble door panels to form door assembly. See Slide Door Panel Assembly page 16.

8.

Hang door (I) on Trolley Trucks.

a.

Two 9/16” round holes on top of door assembly match trolley bolts.

b.

Trolley bolts should have one nut above and below door frame; upper “jam” nut should be backed off until door operation is finalized.

9.

Lag door guide (M) to floor with two floor anchors see Fig 4.

10.

Raise door to desired sweep space using lower trolley nut.

a.

Stock doors without lower angle cover bar have 3-1/4” sweep space.

b.

Stock doors with lower angle cover bar have 1-3/4” sweep space.

c.

Door must be level for proper operation.

11.

Door should slide freely, if not check that trolley trucks are properly aligned in track.

12.

If applicable, install cylinder lock in door, see page 11.

13.

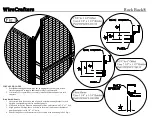

Install Lock Receiver (N). See Fig 5. and slide door receiver instructions on page 17.

14.

Fine tune door by tightening/loosening trolley truck nuts.

a.

When door operates smoothly and locks consistently, tighten top jam nut.

b.

Be sure not to cock trolleys sideways when tightening jam nut. It may be necessary to hold bolt with pliers while tightening jam nut.