1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

C

Instruction de montage

Assembly instructions

NO

T290735_A - 03/2019

12

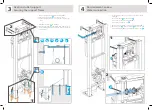

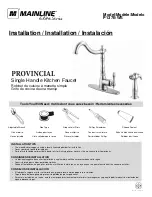

Attachment of the flush plate

Fixation de la plaque de commande

9

1

2

3

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

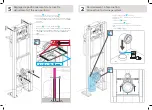

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

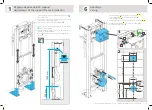

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

1

2

1 - Clipper le cable du mécanisme au support de commande

K

en tirant

horizontalement (figure

1

),

2 - Clipper le support de commande

K

dans le support de plaque

J

(figure

2

),

3 - Installer la plaque de commande

L

en l’inclinant contre le cadre en poussant

vers le haut (action

1

de la figure

3

) puis rebasculer la plaque sur la partie

haute du cadre (action

2

de la figure

3

).

1 - Clip the mechanism cable to the control support

K

by

pulling

horizontally (figure

1

),

2 - Clip the control support

K

in the plate support

J

(figure

2

),

3 - Install the flush plate

L

by tilting it against the frame while

pushing upwards (action

1

of figure

3

) and tilt it back onto

the top part of the frame (action

2

on figure

3

).

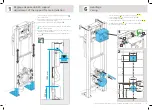

100

360

175 - 280

1063 - 1278

288 - 503