2

11

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

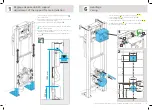

A

B

C

F

G

H

L

I

J

K

M

R

S

W

T

U

V

N

O

P

Q

D

E

B

A

C

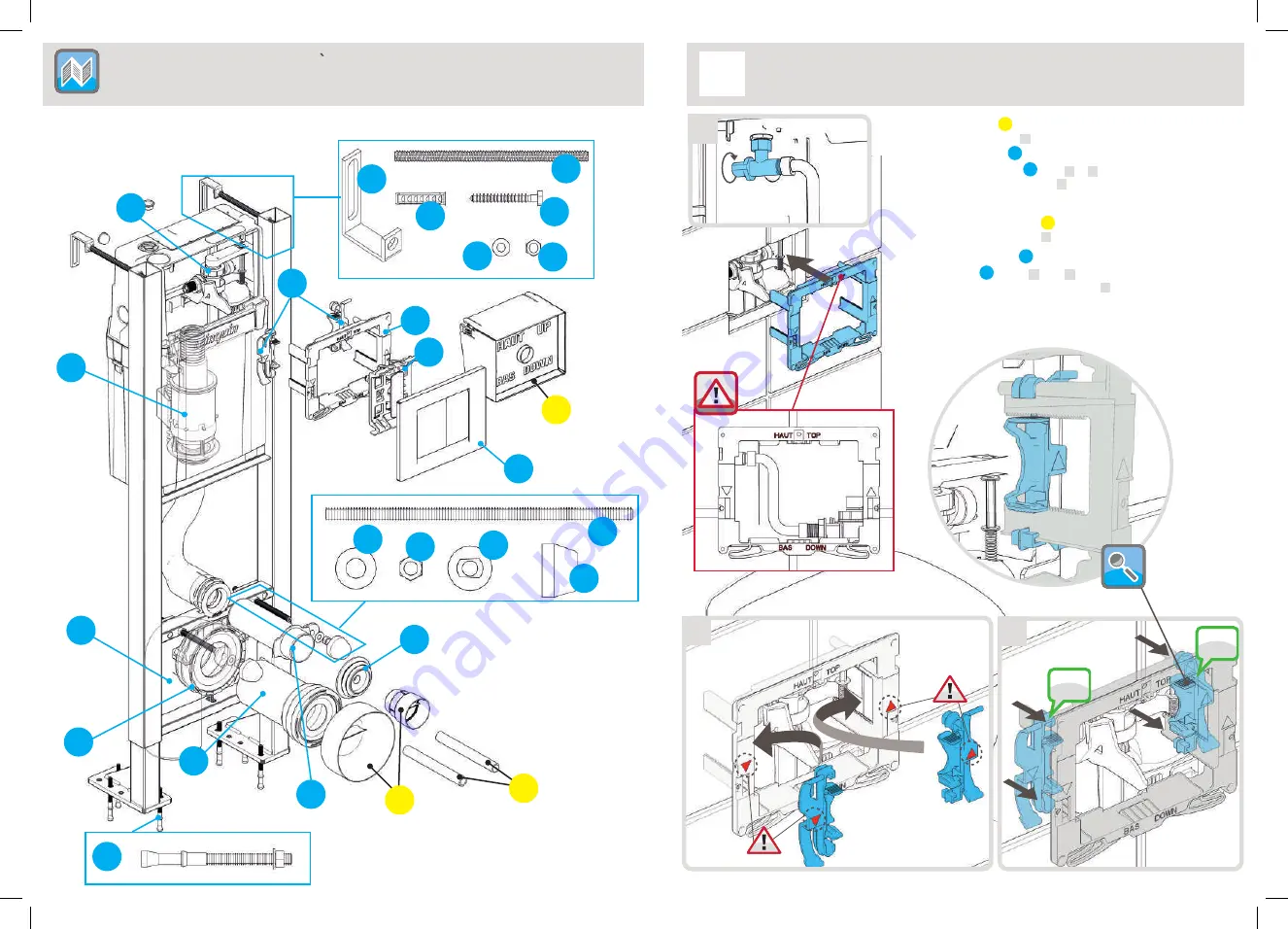

Nomenclature des pieces

Parts list

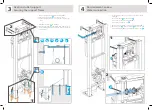

Attachment of the flush plate

Fixation de la plaque de commande

8

1

2

3

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

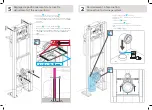

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

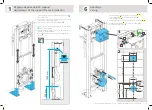

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

1 - Retirer le tunnel gabarit

A

, en tirant horizontalement,

2 - Ouvrir le robinet d’eau (figure

1

),

3 - Insérer le support de plaque

J

dans l’emplacement de la plaque de commande et fixer

le à l’aide des crochets support

I

(figure

2

et

3

) en respectant le sens de montage

(sens des triangles en rouge sur la figure

2

), le support doit se verrouiller sur l’épaisseur

de l’habillage.

1 - Remove the tunnel template

A

, by pulling horizontally,

2 - Open the water valve (figure

1

),

3 -

Insert the plate support

J

in the flush plate position and secure it with

support hooks

I

(figure

2

and

3

) in the correct mounting direction

(orientation of the red triangles on figure

2

), the support must be

locked onto the thickness of the casing.

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !

1h30

1h00

30 mn

15 mn

10 mn

1

2

3

clic !