O p e r a t i n g I n s t r u c t i o n s

OKTOPUS

®

GLASS-Jack

GL-RN 400/600/800

Technical Documentation

BA 000 101

Page 18 of 27

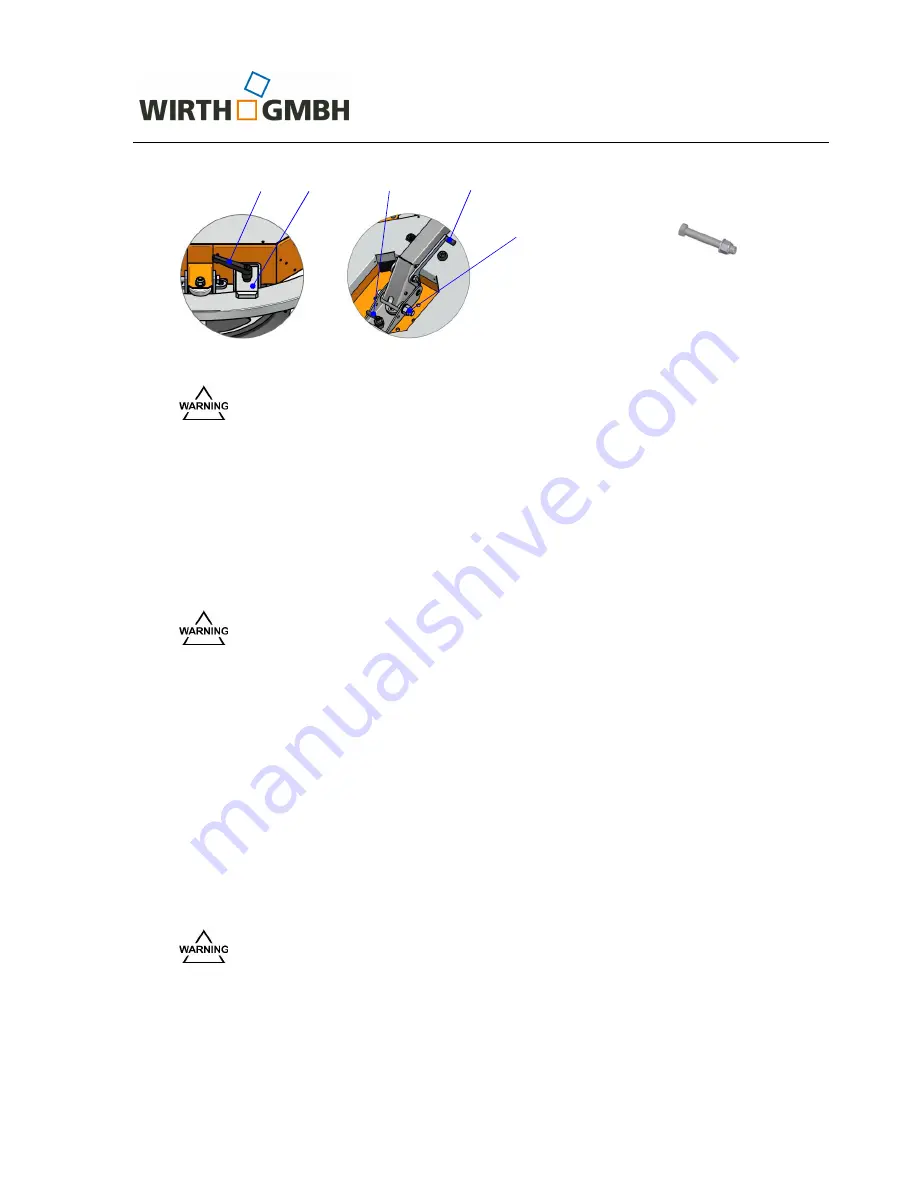

Fig. 12:

OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with guide ring resp. crane arm

Due to the dead weight of the OKTOPUS

®

, a residual vacuum remains even af-

ter ventilating the suction pads by the evacuated system. Jerky rising of the

OKTOPUS

®

strengthens this effect. Therefore, take the equipment always

slowly and steadily off from the elements shifted.

3.5.3 Rotating a load hanging in a vertical position with the

OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with a crane arm

⇒

Suck the element as described in 3.5.2!

Never unlock the release ’’Rotation“ and ’’Swivelling“ at the same time! Un-

locking both the releases may cause damages to the attachment and/or the

load!

⇒

Before rotating the load, make sure that there is enough space available. Ensure that the

load does not strike anything during rotation!

⇒

Unlock the release ’’Rotation“ (see fig. 12) and turn the load into the appropriate position.

After that relock the sliding lever.

3.5.4 Rotating a load hanging in a vertical position with the

OKTOPUS

®

GLASS-Jack GL-RN 400/600/800 with guide ring

⇒

Suck the element as described in 3.5.2!

⇒

Position the OKTOPUS

®

above the centre of mass of the load (max.

±

5 cm).

To avoid unintended load rotation, make sure that upon use of the version

GLASS-Jack GL-RN 400/600/800 with guide ring, the eccentric lever guide ring

(see fig. 12) shall be tightened!

⇒

Before rotating the load, make sure that there enough space is available. Ensure that the

load does not strike anything during rotation!

⇒

Slowly release the eccentric lever guide ring (see. fig. 12)!

⇒

Turn the load into the appropriate position.

⇒

Engage the clamping again by moving the eccentric lever!

1 Eccentric lever guide ring

2 Show brake

3 Release „Rotation“

4 Release „Swivelling“

Hexagon bolt M20 x 140,

washer, lock nut

1 2 3 4