MI 1061 10

idle adjustment

is for smooth low speed operation and

this adjustment, if necessary, must be made with the

carburetor throttle lever closed.

For further information on the carburetor, see the

Zenith operating and service instructions in the rear

of this manual.

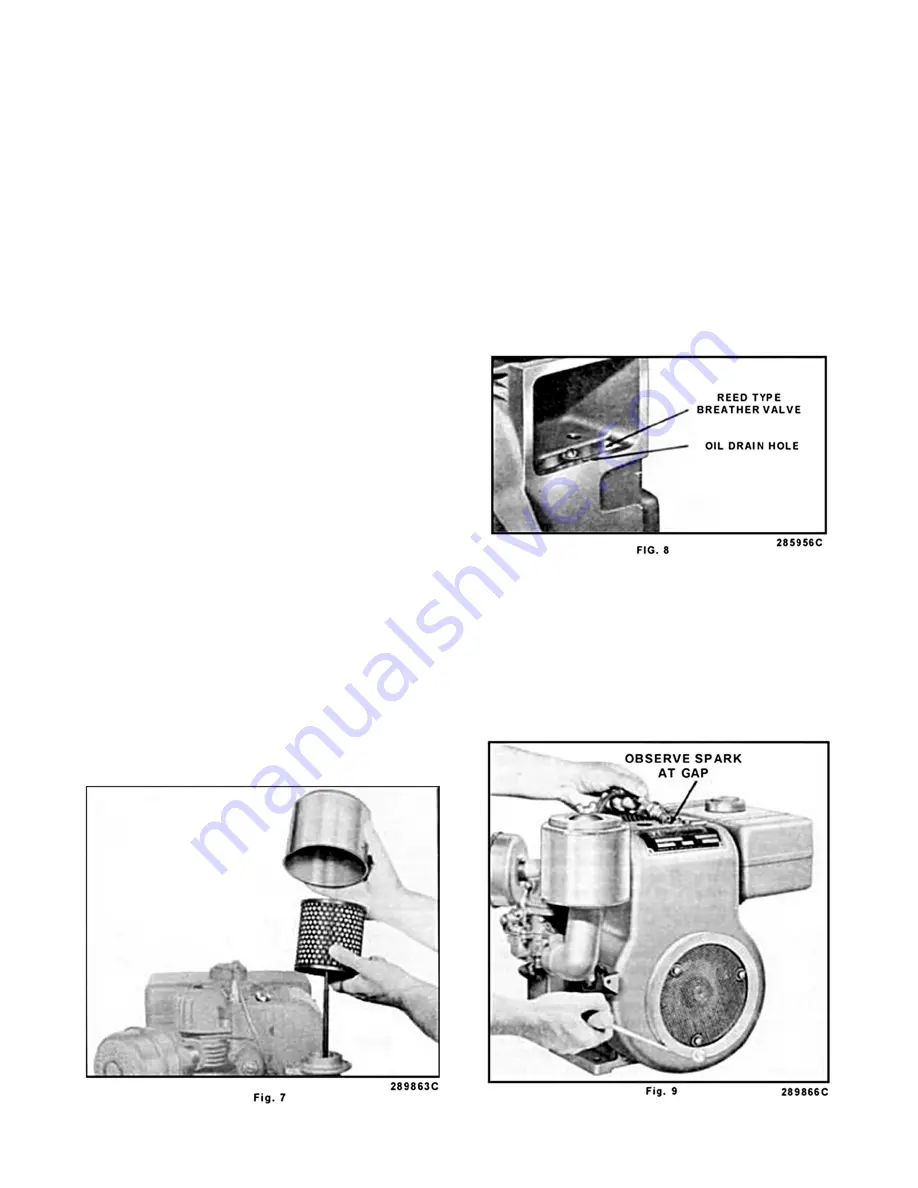

AIR CLEANER

The

dry element

air cleaner, illustrated in

Fig. 7

,

must be serviced frequently, depending on dust condi-

tions where the engine is being operated.

Operating the engine under dusty conditions

without servicing the air cleaner may wear out

cylinder, piston, rings and bearings in a few days

time, and result in costly repairs.

The filter cartridge is easily removed by unscrewing the

wing nut and taking off the cover.

See Fig. 7

.

Service daily,

if engine is operating in very dusty

conditions. Remove cartridge and shake out the ac-

cumulated dirt (do not tap or strike element – it may

become damaged). Wipe out dirt from inside cover.

Once each week;

the filtering cartridge should be

taken out and rinsed under a faucet with cold water,

then wash by repeated dipping for several minutes in

a solution of lukewarm water with a mild,

non-sudsing

detergent. Rinse in cold water from the inside out,

and allow to dry overnight before installing. In cold

weather, protect element from freezing until dry.

Do not use gasoline, kerosene, or solvent for cleaning

– Do not oil element.

After five washings or one year of service, replace

cartridge. New cartridges are available at you

Wis-

consin Motor dealer

. Refer to parts list section for re-

placement part number.

CRANKCASE BREATHER

A

reed

type

breather valve

is located in the valve

spring compartment, as illustrated in

Fig. 8

. The

valve maintains a partial vacuum in the crankcase,

and thus eliminates internal crankcase pressure that

would cause oil leaks at the seals, gaskets and

breaker box. Keep complete breather system free from

dirt, and replace reed if it becomes damaged.

Oil in breaker box

is the direct result of faulty

breather action caused by dirt stuck between reed

and seat. This condition can be remedied in the fol-

lowing manner:

1.

With engine running at operating speed, pinch neo-

prene breather line so that it is completely shut off.

2.

Hold tubing closed, for a period of not more than

20 seconds, and then release.

3.

If oil leak continues, repeat procedure after a 5

minute interval. If this does not remedy the condi-

tion; stop engine and take off valve inspection

plate. Remove breather and clean seats.

IGNITION SPARK

If difficulty is experienced in starting the engine or

if engine misses firing, the strength of the ignition

spark should be checked; remove spark plug and lay

it across the cylinder head. Turn engine over several

times by means of the rope starter sheave, as illus-

trated in

Fig. 9

, and observe the spark at the plug gap.

If a good strong spark occurs, the ignition system

can be eliminated as the source of trouble. If there is

Summary of Contents for Air Cooled TR-10D

Page 6: ...MI 937 2 4 Fig 1 289860C TAKE OFF rear and LEFT HAND SIDE VIEW of ENGINE...

Page 7: ...5 MI 938 2 FAN END front and RIGHT HAND SIDE VIEW of ENGINE...

Page 8: ...MI 939 2 6 SECTIONAL VIEWS OF ENGINE...

Page 28: ......

Page 29: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Page 30: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Page 31: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 44: ......

Page 46: ...WISCONSIN MOTOR CORPORATION MILWAUKEE WISCONSIN 532466 PRINTED IN U S A...