1 MI-7-17

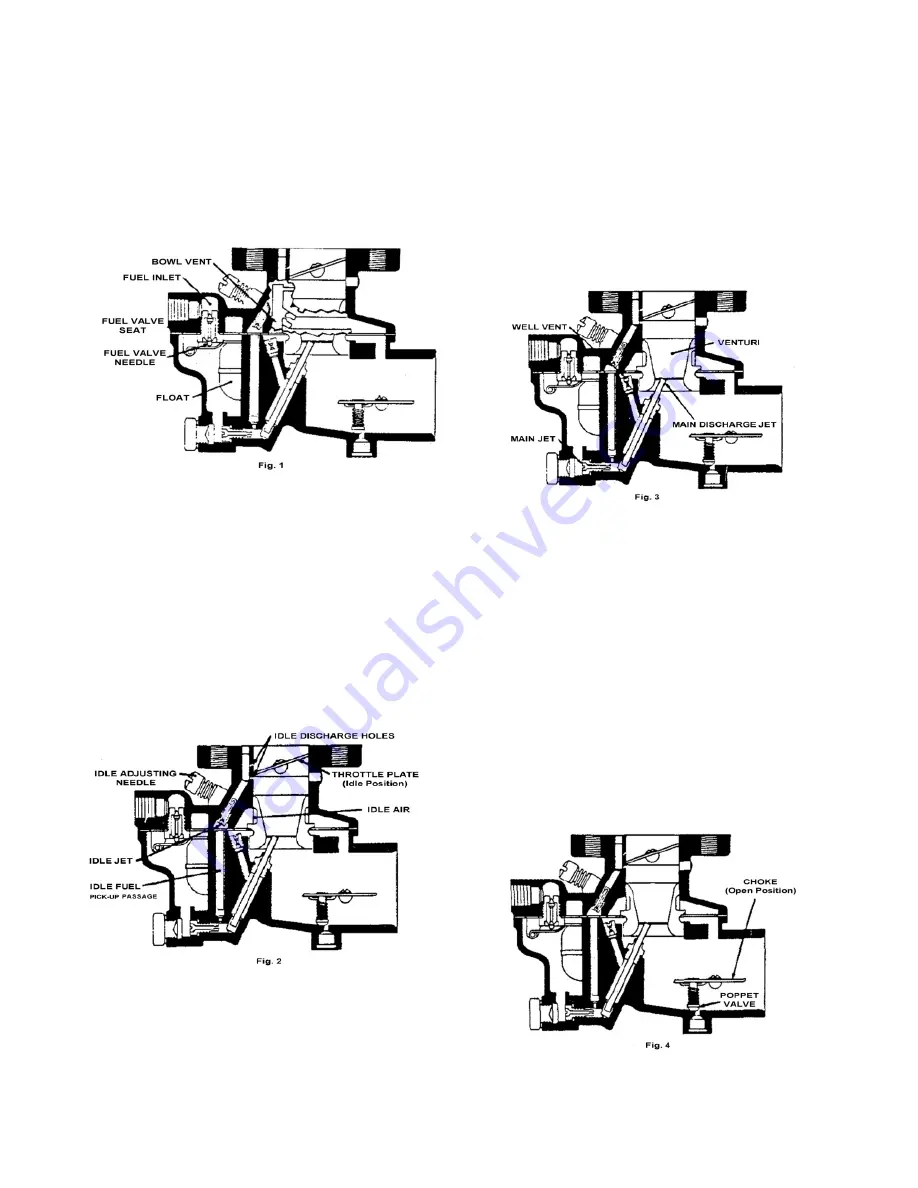

The Zenith 68-7 Series carburetor is of an up-draft single venturi

design with a 1" S.A.E. barrel size and a 7/8" S.A.E. flange.

The carburetors are made with selective fuel inlet, and with or

without a main jet adjustment. These carburetors are “balanced"

and "sealed', and the semi-concentric fuel bowl allows operation

to quite extreme angles without flooding or starving. This design

makes them particularly adaptable to smaller farm tractors and a

great variety of agricultural machines and industrial units.

Fuel supply system

, Fig. 1, is made up of the threaded fuel inlet,

the fuel valve seat, fuel valve needle, float and fuel bowl.

The fuel supply line is connected to the threaded inlet. The fuel

travels through the fuel valve seat and passes around the fuel

valve and into the fuel bowl. Te level of fuel in the fuel

chamber is regulated by the float through its control of the fuel

valve. The fuel valve does not open and close alternately but

assumes an opening, regulated by the float, sufficient to maintain

a proper level in the fuel chamber equal to the demand of the

engine according to its speed and load.

The inside bowl vent as illustrated by the passage originating in

the air intake and continuing through to the fuel bowl, is a method

of venting the fuel bowl to maintain proper fuel mixtures even

though the air cleaner may become restricted. This balancing is

frequently referred to as an “inside bowl vent”.

Idle system

, Fig. 2, consists of two idle discharge holes, idle

air passage, idle adjusting needle, idle jet, and fuel pick-up

passage.

The fuel for idle is supplied through the main jet to a well direct-

ly below the main discharge jet. The pick-up passage is connect-

ed to this well by a restricted drilling at the bottom of this pas-

sage. The fuel travels through this channel to the idle jet cali-

bration. The air for the idle mixture originates back of (or from

behind) the main venturi. The position of the idle adjusting nee-

dle in this passage controls the suction on the idle jet and there-

by the idle mixture. Turning the needle in closer to its seat re-

sults in a greater suction with a smaller amount of air and there-

fore a richer mixture. Turning the needle out away from its seat

increases the amount of air and reduces the suction, and a leaner

mixture is delivered. The fuel is atomized and mixed with the air

in the passage leading to the discharge holes and enters the air

stream at this point.

High speed system,

Fig. 3, controls the fuel mixture at part throt-

tle speeds and at wide open throttle. This system consists of a

venturi, controlling the maximum volume of air admitted into the

engine; the main jet, which regulates the flow of fuel from the

float chamber to the main discharge jet, the well vent, which

maintains uniform mixture ratio under changing suction and en-

gine speeds; and a main discharge jet which delivers the fuel

into the air stream.

The main jet controls the fuel delivery during the part throttle

range from about one-quarter to full throttle opening. To maintain

a proper mixture ratio a small amount of air is admitted through

the well vent into the discharge jet through the air bleed holes in

the discharge jet at a point below the level of fuel in the meter-

ing well.

The passage of fuel through the high speed system is not a com-

plicated process. The fuel flows from the fuel chamber through

the main jet and into the main discharge jet where it is mixed

with air admitted by the well vent, and the air-fuel mixture is

then discharged into the air stream of the carburetor.

Choke system,

Fig. 4, consists of a valve mounted on a shaft

L-63 Series

ZENITH 68-7 SERIES CARBURETOR

Wisconsin Motor Corporation Part No. L-63 Series

Summary of Contents for Air Cooled TR-10D

Page 6: ...MI 937 2 4 Fig 1 289860C TAKE OFF rear and LEFT HAND SIDE VIEW of ENGINE...

Page 7: ...5 MI 938 2 FAN END front and RIGHT HAND SIDE VIEW of ENGINE...

Page 8: ...MI 939 2 6 SECTIONAL VIEWS OF ENGINE...

Page 28: ......

Page 29: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Page 30: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Page 31: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 44: ......

Page 46: ...WISCONSIN MOTOR CORPORATION MILWAUKEE WISCONSIN 532466 PRINTED IN U S A...