11

3.5 Laser Power Supply installation

1)

Laser tube wire installing:

2)

Distinguish correctly the laser tube’s positive and cathode, As usual, laser output port is cathode (-), then the

other is the anode (+).

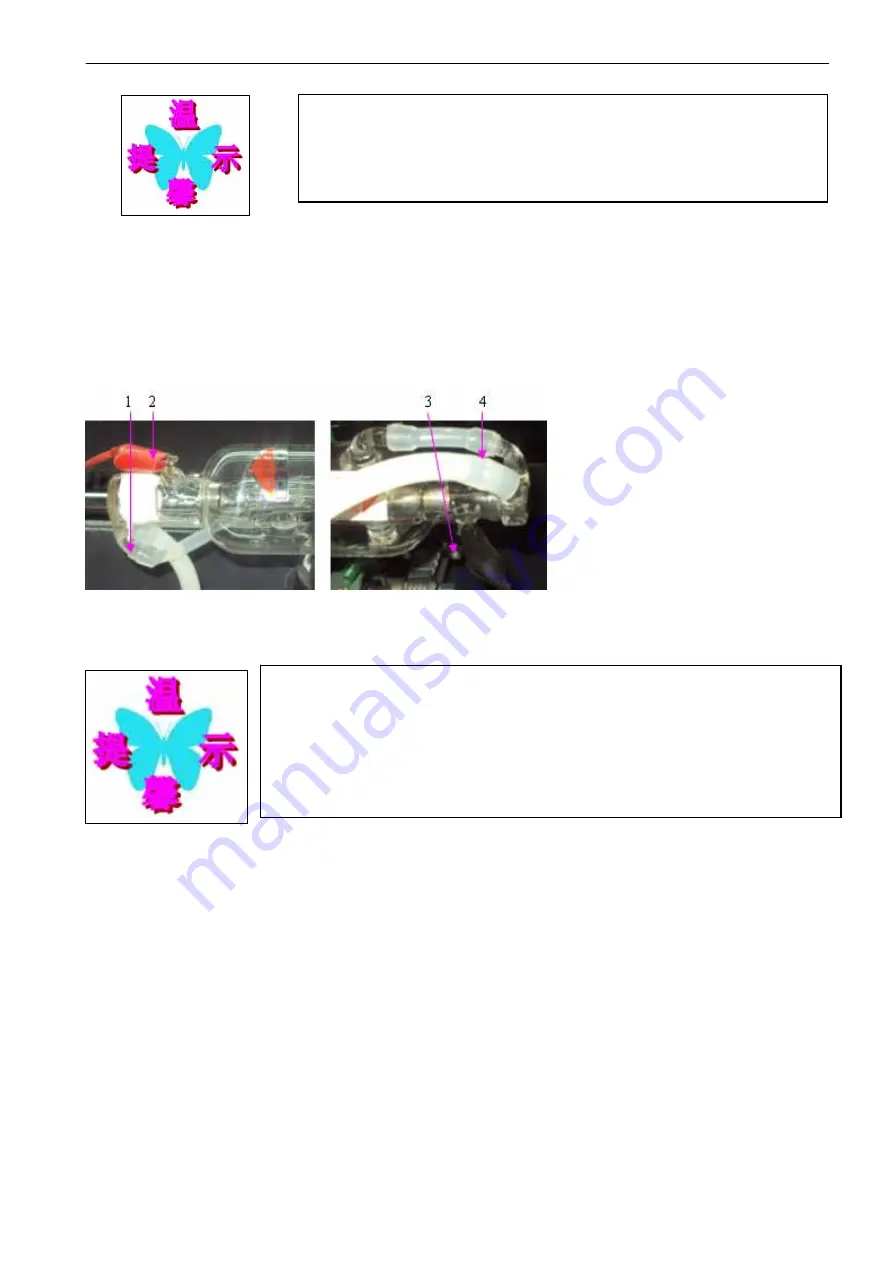

1. Water inlet of the tube 2. Anode (+) of the laser tube

3. Water outlet of the tube 4. Cathode (-) of the laser tube

3.6 Water chiller installation

:

Connect the rubber pipe with the laser tube and water chiller. The outlet of the water chiller connects the inlet of

the machine, the inlet of the water chiller connects the outlet of the machine . After one minute of water circulation,

please check out whether there is any bubble in the laser tube. If there is, please turn over the tube to push the bubble

out.

z

The cooling water could not frozen in cold regions, especially

after the machine stop working, guarantee there is no cooling

water within the laser tube to avoid the crack generated by

cooling water frozen.

z

Please note: the driving way of the laser tube is high-voltage drive, and

the work voltage is about more than 18KW, To avoid electrical shock,

please electrostatic discharge before dismounting the power,

z

Please differ the positive and negative poles, don’t connect them

wrongly; or else will effect the lifetime of the laser tube, even damage to

it;