7

• Have your stove and chimney system installed by a certi

fi

ed stove installer or licensed contractor.

• All installations must meet local codes.

• Use 4, 5 or 6 inch standard class A 103 HT exhaust chimney system.

• Use a minimum of 24 gauge, 4 inch or larger connector pipe.

• This is a wood stove that burns wood pellet fuel, this means natural draft is running the stove, it must

be treated as a wood stove with the pipe installation being as vertical as possible to obtain maximum

upward draft.

• Horizontal runs and elbows are discouraged.

• Do not install a

fl

ue damper in the exhaust vent.

DO NOT CONNECT THIS UNIT TO CHIMNEY FLU SERVING ANOTHER APPLIANCE.

Chimney connector must be in good condition and kept clean. Exhaust venting system termination

requirements, including location restrictions: relationships to air inlets, distance from windows, doors, air inlets,

and distance to combustible materials MUST BE MAINTAINED AT ALL TIMES.

For residential use Install only with a chimney complying with the requirements for class A 103 HT chimneys

in the standard for chimneys, Factory built, residential type and building heating appliance.

Stove is also Mobile home approved in the U.S. but not in Canada. Mobile home installation also requires

that a direct outside air kit be installed and the stove be bolted or fastened to the

fl

oor and a #10 copper

wire be attached to the stove and then attached to the frame of the manufactured home to ground the

stove. Only approved pellet vent can be used. No single wall connector pipe is allowed in a Mobile Home.

For mobile home use (US ONLY) Install with class A 103 HT chimney using 4, 5 or 6 inch diameter with ceiling

trim plate, attic insulation shield,

fl

ashing, storm collar and cap. 4, 5 or 6 inch dual wall connector pipe can

be used to chimney.

WARNING: DO NOT INSTALL IN A SLEEPING ROOM! CAUTIONS: STRUCTURAL INTEGRITY OF THE MOBILE HOME

FLOOR, WALL, AND CEILING/ROOF MUST BE MAINTAINED.

When this room heater is not properly installed, a house

fi

re may result. To reduce the risk of

fi

re, follow the

installation instructions. Contact local building or

fi

re of

fi

cials about restrictions and installation inspection

requirements in your area.

For basement use, Install only with a chimney complying with the requirements for class A 103 HT chimneys

in the standard for chimneys, Factory built, residential type and building heating appliance, outside air source

must be supplied.

DO NOT CONNECT TO OR USE IN CONJUNCTION WITH ANY AIR DISTRIBUTION DUCT WORK UNLESS SPECIFICALLY

APPROVED FOR SUCH INSTALLATION.

Taler or longer chimney system’s may need a barometric damper installed immediately off the top of the

stove to be able to control the stove down in the 400° range as you can experience excessive draft and the

stove will want to run hotter.

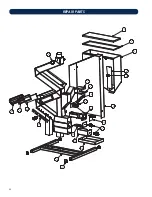

STOVE PIPE INSTALL/ HELPFUL HINTS