24

6

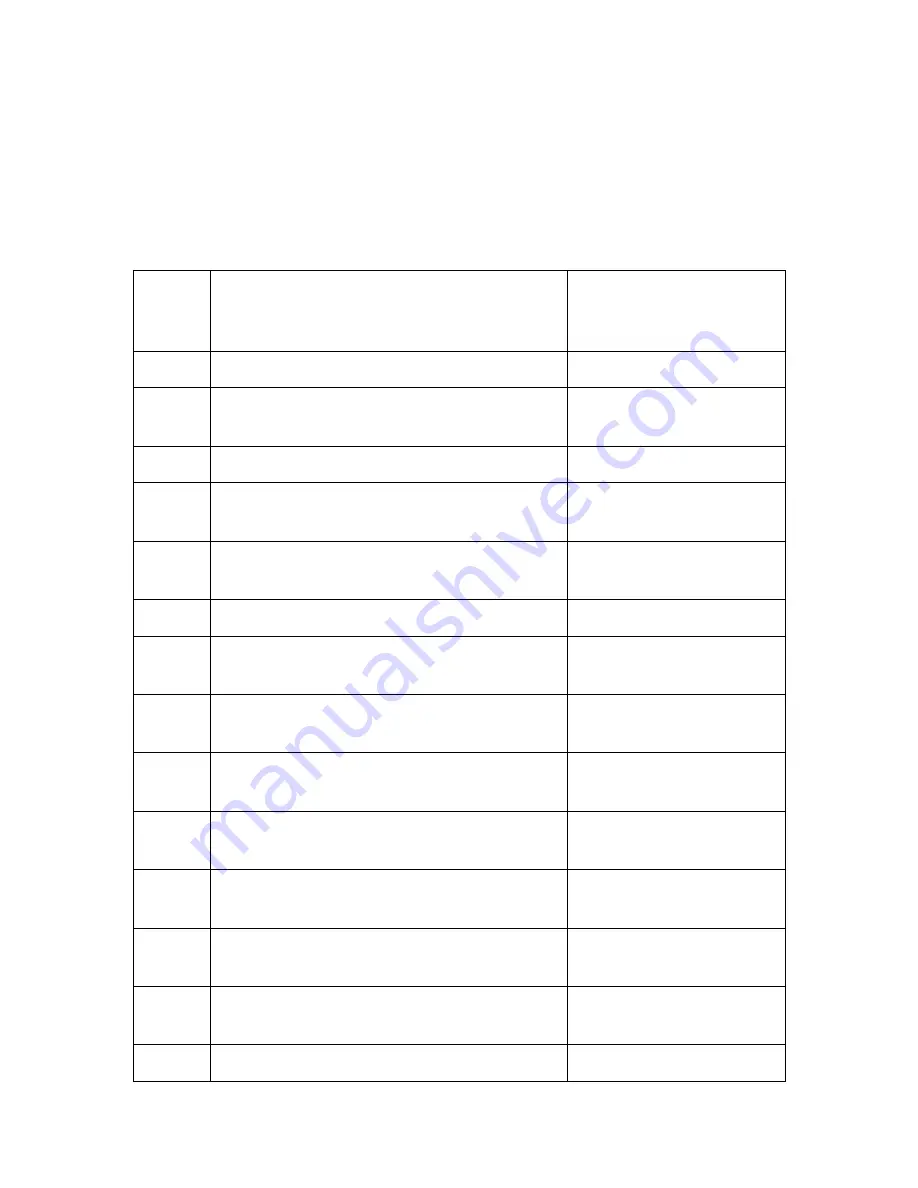

Pre Delivery Inspection check list

The PDI is a critical part of the overall Quality Assurance process and must be completed by the

supplying dealer followed by a test ride and sign off before passing the bike to the customer.

The following items below are a generic list for all current Wisper models and must be covered

during the PDI.

Item

Check off

by No.

Activity

Mechanical Parts

Notes

1

Check front and rear wheel for alignment and run out Tighten spokes if necessary

2

Check tightness of rear axle nuts and front quick

release

Tighten to torque setting in

user manual

4

Check tyre pressures front and rear

Inflate to correct pressure

5

Check and adjust action of front and rear brakes

Ensure there is no noise or

squeal

6

Check smooth action and adjustment of front

suspension forks

7

Check adjustment of bearings in headstock

Adjust if necessary

8

Check security of all handlebar stem fixings and

clamps

Adjust to suit customer

preferences

9

Check front and rear mudguards for security and

clearance from tyres

10

Check all cables are clipped securely and safely

Check motor cable cannot rub

against the tyre

12

Check pedals have been fitted correctly and tightened

fully

Note left and right hand

threads

13

Check pedal cranks have been tightened fully on

bottom bracket axle.

Tighten to torque setting in

user and service manual

14

Check smoothness and running clearance of bottom

bracket

15

Check seat post quick release clamp is properly in

place and secure and saddle is correctly fitted.

Adjust as necessary

16

Check smooth operation of gear change on either

Adjust as necessary