5/16

ProphyCair & Pro

Version: 01

ENGLISH

2

Contraindications

All air mattress systems are contraindicated for patients

with cervical traction or unstable:

Spinal fractures

Spinal cord injury

Also:

Fractures at risk of complication by a moving

support surface.

Trauma patients where spinal injuries have not

been excluded or ‘cleared’.

CAUTION

For patients undergoing cervical traction the use of the LAL

mode is contraindicated and the use of LAL and PT modes

should only be under the direction of a suitably qualified

physician.

Before placing a patient on an air mattress, a risk assess-

ment by a suitably qualified person should be completed,

to ensure the appropriateness of the support provided.

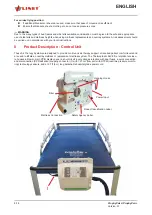

3

Technical Specifications

Electrical Specifications

NOTE

The control unit Power Inlet is used as the means of

isolating the equipment from the supply mains on all poles

simultaneously.

Parameter

Value

Input Voltage AC

90 ~ 240 VAC

Input Frequency

60 / 50 Hz

Maximum Power Consumption

180 W ± 30 W

Circuit Protection

Dual fused, 250V, 5A

Fast blow fuse(s), std.

fuses

Fuse Type

Bussmann S500-5-R

Breaking Capacity

@125 VAC is 10kA

@250 VAC is 200A

Mode of Operation

Continuous

Performance Specifications

Parameter

Value

Weight capacity

Standard replacement mattre-

ss

455 kg

Pressure zones

5

Max. Flow

1275 LPM / 45 CFM

Support Surface Inflation Time

Within 120 seconds

(Max Inflate)

Patient Comfort Pressures / Alternating Pressure

Parameter

Value

Soft Pressure

7 ± 5 mmHg

Firm Pressure

32 ± 5 mmHg

Patient Contact

Control unit and the mattress are

lead free

,

mercury free

and

latex free

components.

Dartex top sheet is Halogen-free (bromide-free).

Mechanical Specifications

Parameter

Value

Dimensions LxWxH

ProphyCair

Prop

ProphyCair Lo

ProphyCair Lo +

200 x 87 x 20,5 cm

200 x 99 x 25 cm

200 x 87 x 18 cm

200 x 99 x 18 cm

Weight

4 kg (CU), 7 kg

(mattress)

Power cord

600 cm

Connection

1.27 cm flow single

quick disconnect co-

nnector

Packaging

1 piece per box

PLEASE CLEAN FILTER EVERY 3 MONTHS OR

WHENEVER DIRTY

Remove 2 thumb screws and separate filter foam from

filter cover. Wash filter foam using soap and water. Dry and

replace filter and filter cover on the unit and

fasten screws.

Support Surface

Air cushions are high frequency heat sealed, liquid proof

and washable. Base is liquid proof and washable.

Top Sheet is low friction, low shear, low force producing,

breathable, liquid resistant and highly vapor permeable.

Material is 70 Denier nylon or Dartex and a bottom foam

or air pad on the bottom of the air cushions enclosed in a

cover.