cyber

®

simco

®

drive 2 operating manual

Revision: 02

5022-D057946

en-41

de

utsch

english

fra

nçais

ita

lia

no

es

pa

ñol

日本語

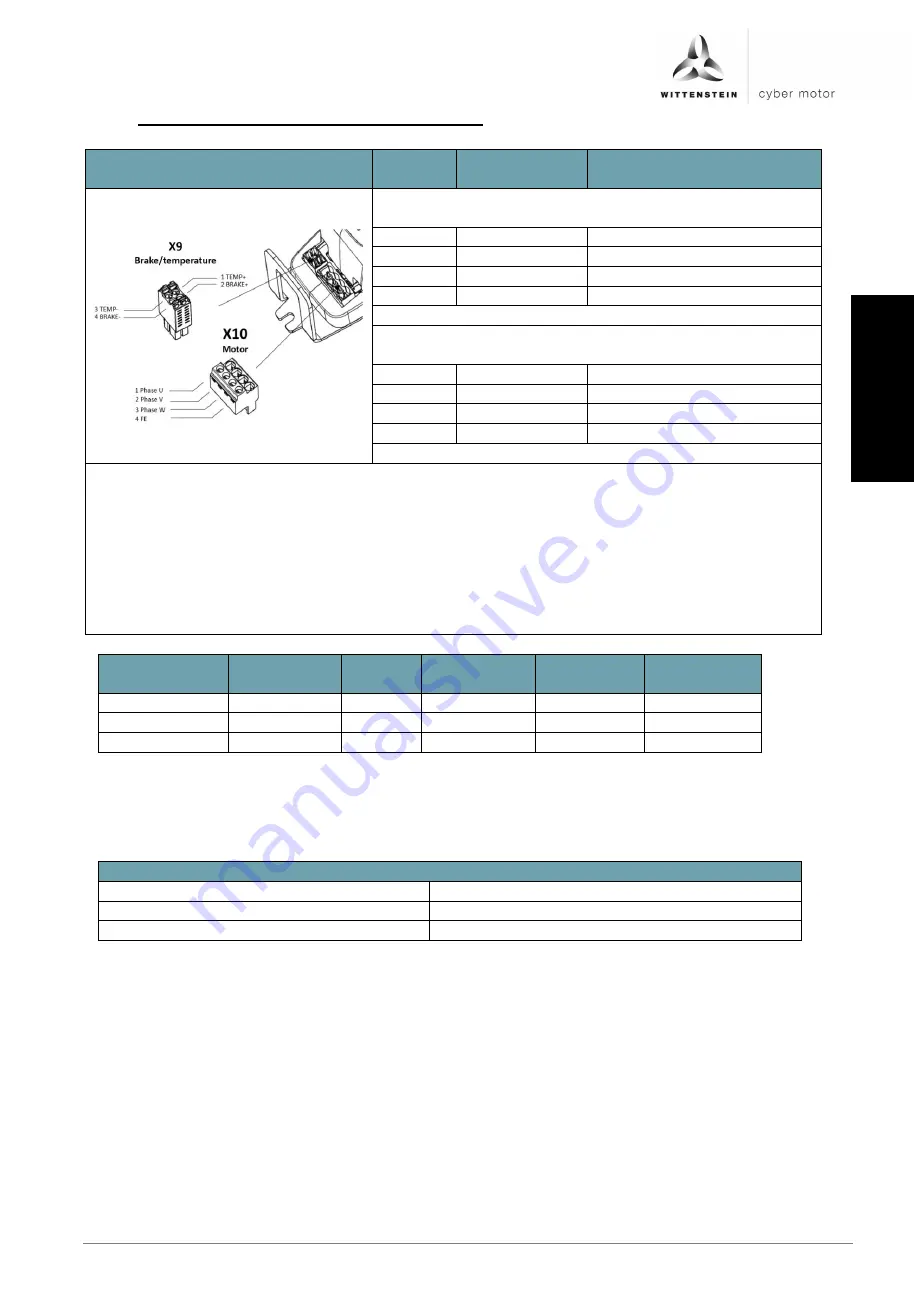

6.6.12 X10: Motor / brake / temperature connection

Figure

Pin no.

Signal name

Function

Motor plug X10

1

PHASE_U

Motor phase U

2

PHASE_V

Motor phase V

3

PHASE_W

Motor phase W

4

FE

Functional earth

Brake/temperature plug X9

1

TEMP+

Motor temperature

2

BRAKE+

Holding brake +

3

TEMP-

Motor temperature sensor -

4

BRAKE-

Holding brake -

Plug type X9 Dinkle 0159-0304

Permissible wire cross-section: AWG 24..26

Stripping length: 8 mm

Plug type X10 on Dinkle 0181-A303

Permissible wire cross-section: AWG 24..12

Stripping length: 8 mm

Tightening torque: 0.5 ... 0.6 Nm; the tightening torque must be 0.5 Nm to conform to the

UL requirement

Connection

Feature

Unit

Minimum

value

Nominal

value

Maximum

value

PHASE_x

Current

Aeff

15

1

/ 7.5

2

30

1

/ 15

2

BRAKE+/-

Voltage

V DC

24

Connection

Current

A DC

0.8

1

: SIM2015D

2

: SIM2007D

The following overview shows the correct wiring of the motor phases of cyber

®

dynamic line

via the adapter cables S/L-cable xxxHI-xxxx-BA0-6/3:

Connection schematic

U

Red

V

White

W

Black

Summary of Contents for Cyber Simco Drive 2

Page 1: ...5022 D057946 Revision 02 cyber simco drive 2 Operating manual ...

Page 2: ......

Page 56: ......