SP

+

Assembly

Revision: 03

2022-D033540

en-11

z

Smear screw-bonding agent (for example Loctite 243) onto the four bolts (F).

z

Fasten the motor (D) onto the adaptor plate (B) with the four screws (F).

z

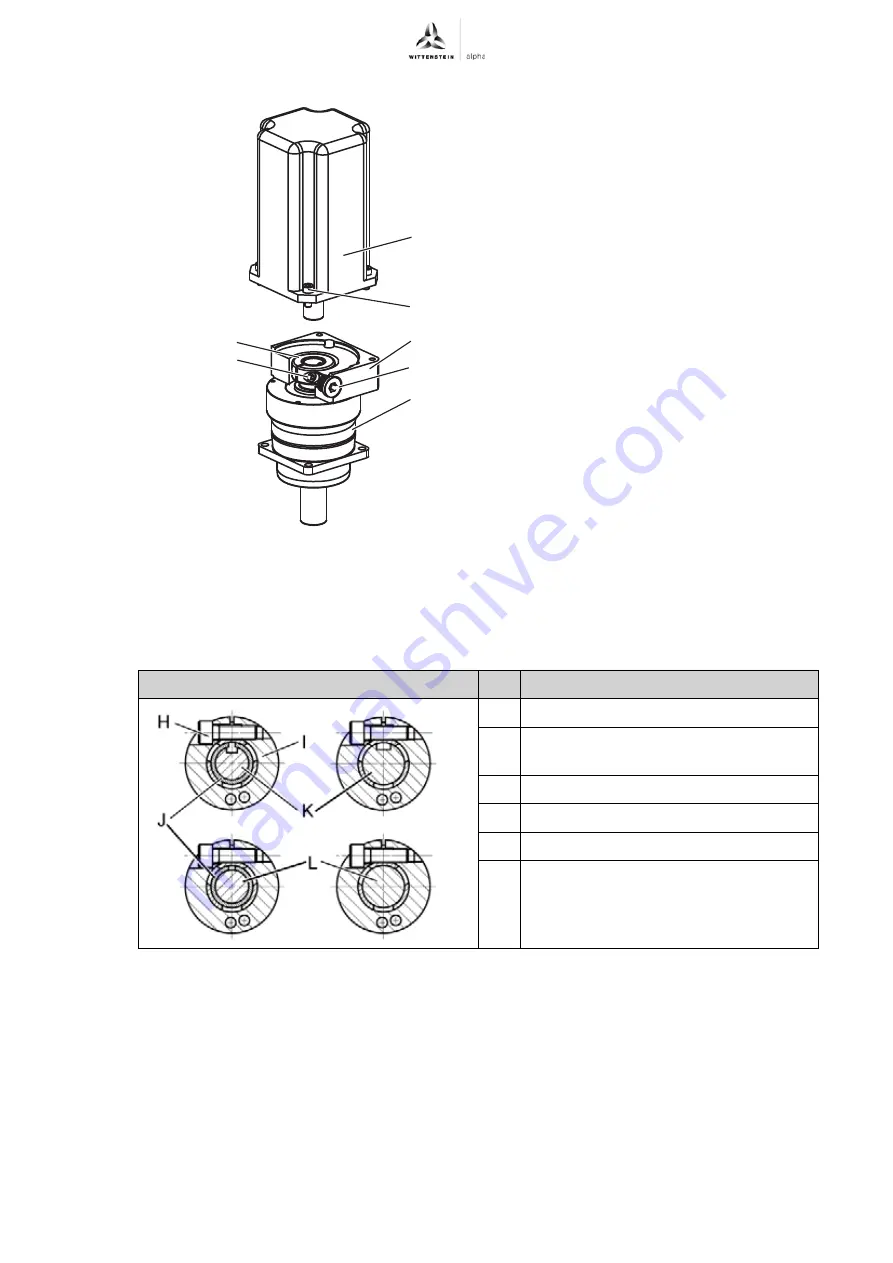

Select the tightening torque for the clamping bolt (H) according to the material of the clamping

ring (I).

- Clamping bolt for

steel

clamping ring: Property class 12.9

- Clamping bolt for

aluminum

clamping ring: Property class 8.8

L

For bolt sizes and specified torques refer to chapter 9.1 "Specifications on mounting onto a

motor", tables "Tbl-14".

z

Ensure that the motor is mounted if possible in

a vertical direction.

z

If the motor shaft has a shaft key, remove the

shaft key.

L

If recommended by the motor manufacturer,

insert a half wedge.

z

Remove the plug (A) from the mounting bore in

the adaptor plate (B).

z

Turn the clamping hub (C) until the clamping

bolt (H) can be reached by the mounting bore.

z

Loosen the clamping bolt (H) of the clamping

hub (C) by one revolution.

z

Push the motor shaft into the clamping hub of

the gearhead (E).

L

The motor shaft should slip in easily. If this is

not the case, the clamping bolt must be

loosened more.

L

A slotted bushing has to be installed extra for

certain motor shaft diameters and

applications.

L

The slot of the bushing (if provided) and

clamping hub have to be flush with the

groove (if provided) of the motor shaft, see

table "Tbl-5".

L

No gap is permitted between motor (D) and

the adaptor plate (B).

Designation

H

Clamping bolt

I

Steel/aluminum clamping ring

[part of the clamping hub (C)]

J

Bushing

K

Keyed motor shaft

L

Smooth motor shaft

Tbl-5: Arrangement of motor shaft, clamping hub, and bushing

A

B

H

C

D

E

F