SP

+

Assembly

Revision: 03

2022-D033540

en-13

5.4.1

Mounting on the slip-on shaft with shrink disk

The slip-on shaft has a smooth design (without keyway). For the load shaft, we recommend the

tolerance h6 (DIN ISO 286). The material must have a minimum yield stress of 385 N/mm

2

. The

slip-on shaft is axially secured to the load shaft by means of a shrink disk connection. If you have

ordered a shrink disk, it has already been installed on the slip-on shaft.

z

In case you use another shrink disk, observe the instructions of the manufacturer.

L

Only the exterior surface of the slip-on shaft may be greased in the area of the shrink disk seat.

z

Slide the slip-on shaft onto the load shaft by hand, taking into account the minimum clamping

length and the maximum permissible depth.

L

For the minimum clamping length and the maximum permitted depth of the slip-on shaft

see Chapter 9.2 "Specifications on mounting on the gear output side", table "Tbl-15".

Dirt can inhibit transmission of the torque.

z

Do not disassemble the shrink disk prior to installation.

z

De-grease the load shaft and the slip-on shaft bore in the area of the

shrink disk seat, leaving no residual traces.

The forces of the shrink disk can deform the slip-on shaft.

z

Always install the load shaft first before tightening the clamping screws

of the shrink disk.

A jamming of the shafts can lead to damage.

z

Make sure that the slip-on shaft is aligned with the machine shaft.

z

Mount the slip-on shaft onto the machine shaft without using force.

z

Do not on any account attempt an assembly by hammering or applying

pressure.

z

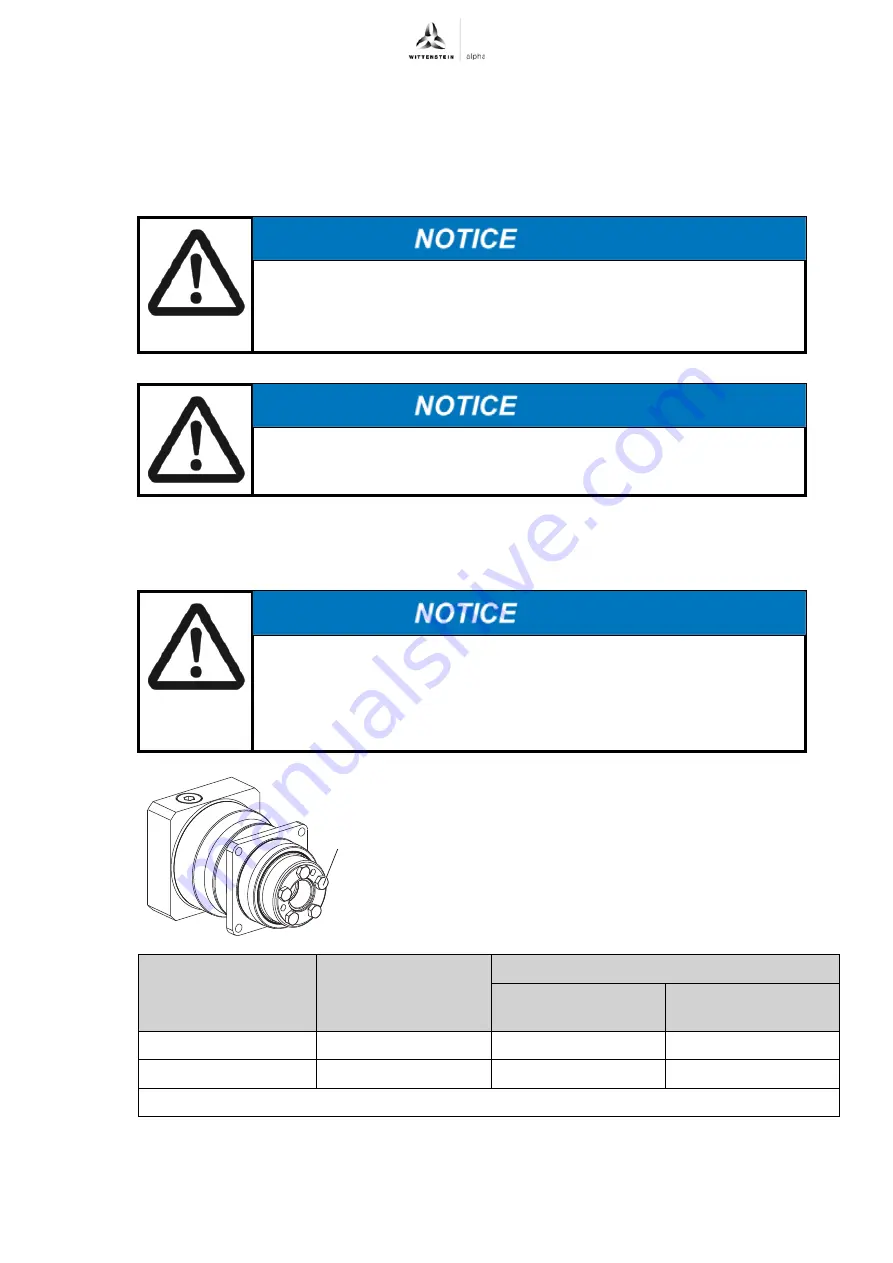

Tighten the clamping screws (A) of the shrink disk

evenly distributed in multiple circular passes.

z

Tighten the individual clamping screws only up to

the maximum permitted tightening torque.

L

For bolt sizes and specified torques see

table "Tbl-8".

Gearhead size

SP

+

Clamping screw

thread

Tightening torque [Nm]

Property class

10.9

Property class

Ax-80 )

1

060, 075

M6

12

9

100 to 180

M8

29

21

)

1

Ax-80 = stainless steel (optional)

Tbl-8: Tightening torques for clamping screws of the supplied shrink disk

A