Gearless Lift Machine

WSG-08

with caliper disk brake

Operating Instructions

Seite/page

14

Datum/date

12.08.2016

Stand/version

0.18

Änderungen vorbehalten! Subject to changes without notice!

7.4. Brake

The brakes are supplied with d.c. voltage by an overexci-

tation rectifier which is installed in the terminal box for

the brakes.

The connecting contacts for the micro-switches which

monitor the brakes are also accommodated in this termi-

nal box.

To reduce the switch-off time, switching

can be effected from the d.c. side. Howev-

er, it is also required to provide switching

from the a.c. side at the same time)!

The overexcitation rectifier is supplied as

standard with a bridge installed between

contacts 3 and 4, meaning that a.c. side

switching is preset.

Repeated switching of the brake magnets

during the overexcitation period must be

avoided as this will result in overloading of

the brake control unit. Therefore, a mini-

mum brake operating time of approx. 1.5 –

2 s should be maintained during an

inspection or commissioning drive.

Note on the use of d.c./a.c. side switching:

A.c. side switching is recommended for nor-

mal operation, since the lift machine is

then decelerated in a controlled manner to

zero speed and the switching noise of the

brake is negligible.

When braking in the event of a breakdown

(emergency stop) or during an inspection

drive, the switching should be performed

from the d.c. side, since this ensures a

faster braking effect with the car being

stopped earlier.

It is therefore recommended to use 2 sepa-

rate contactors for the brake control cir-

cuitry, one of which switching at the d.c.

side, the other one at the a.c. side.

Note

Note

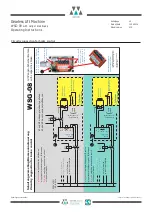

A.c. side switching

•

Low-noise switching of the brake

•

No protective measures required for switching contact

•

Slow application of the brake.

~

+

-

Br

D.c. side switching

•

Noisy switching

•

Burn-up protection for switching contact required

(e.g. varistor, free-wheeling diode)

•

Fast application of the brake.

-

+

Br

~

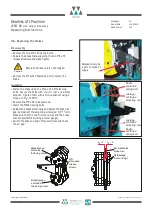

Monitoring the brakes

The switching state of the brakes is monitored using

dust-proof micro switches with gold contacts. The con-

tacts are designed as n.c. contacts, i.e. the contact is

opened if the armature is attracted (brake released). It is

possible to change the micro switch contacts into n.o.

contacts, if required.

The switches must be evaluated separately

for each partial brake to ensure compliance

with the requirements of the type examina-

tion.

Danger

Caution

Attention: schematic diagram !

Attention: schematic diagram !

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......