Gearless Lift Machine

WSG-08

with caliper disk brake

Operating Instructions

Seite/page

18

Datum/date

12.08.2016

Stand/version

0.18

Änderungen vorbehalten! Subject to changes without notice!

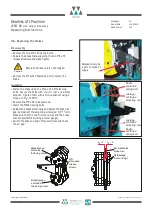

9.3. Lubricating instructions

The main bearing (DE self-aligning roller bearing) has

been filled at the factory with a quantity of grease suffi-

cient for the nominal service life of the machine.

No regreasing is required or recommended under normal

service conditions.

In special cases, e.g. under extreme condi-

tions (max. utilisation of permissible axial

forces at max. nominal speeds), the regreas-

ing device provided can be used. For this

purpose, screw the grease nipple which is

"parked" in a dummy hole on the right

motor foot (view on traction sheave) into

the regreasing hole which is located near

the rotor centre (see picture below).

Before doing this, remove the plug screw

DIN 908-B-M10x1 which protects the

regreasing hole. Use a KP 2 N-30 grease to

DIN 51 502 (e.g. Wälalit LZ2 or Klüberlub BE

41-542). The refilled grease should exert

only slight pressure on the grease column.

Therefore use only a small quantity, max.

0.5 cm³. We recommend "parking" the

grease nipple back in its hole and closing

the regreasing hole after the regreasing.

The (NDE) secondary bearing is life-lubricated and not

provided with a regreasing device.

lubricating nipple in “parking position”

lubricating point

Note

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......