Gearless Lift Machine

WSG-08

with caliper disk brake

Operating Instructions

Seite/page

19

Datum/date

12.08.2016

Stand/version

0.18

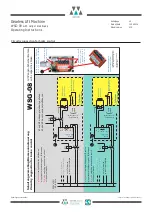

Release lever set with remotely controlled bowden cable

Release lever set with remotely controlled bowden cable

H1

H2

b

handbetätigt

hand-operated

H2

a

fußbetätigt

foot-operated

16

654

403

377

97

14

0

35

2

13

9

2 x

∅

13,5

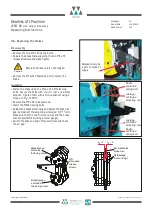

9.4. Emergency evacuation

The lift design engineer

must always provide

for an electric return

motion control or for

a manual rewinder

(please note EN 81-20).

Should a failure occur

with the car at rest, the car can be

moved with the drive connected to

the mains or to an uninterruptible

power supply (UPS) or mechanically

under its own load with the emer-

gency brakes temporarily released.

These brakes are released electrically

either from the mains or using a

UPS.

They can, however, also be released

manually.

For this purpose the brakes are

equipped with a lever plate (16) into

which two ring bolts (e.g. M8 to

DIN 580) spaced 35 mm apart can be

screwed (see "Release lever set with

remotely controlled bowden cable").

By inserting lever rods (dia. max.

20 mm), the brakes can be released

manually.

The brake lever plates and the asso-

ciated counter plates also have holes

and slots to which Bowden cables

can be attached. By using special

lever devices, the brakes can then

also be released remotely by hand

within certain limits. Such devices

are shown in the figure and table

"Release lever set with remotely

controlled bowden cable" This "lever

system" with 3 m Bowden cables

(preferred length 3 m, max. length

6 m) can be supplied on special order.

If the brakes are released with the

motor deenergised, the motor wind-

ings should be short-circuited. This

prevents the lift from accelerating in

an uncontrolled manner since the

short-circuiting produces a speed-

dependent braking torque.

Änderungen vorbehalten! Subject to changes without notice!

Note

WSG-

08.1/2/3

(two brakes)

08.4

(three brakes)

Item in

figure

Assembly

Number

Item no.

Number

Item no.

H1

bowden cable

2

505 656-2

(

preferred length 3 m)

3

505 656-2

(preferred length 3 m)

H2 a

lever support

1

505 045 900

1

505 045 900

H2 b

lever support

1

505 666

1

505 045

L1

220

390

L2

250

430

U1

76

98

U2

93

140

d3 / L3

Æ

16 / 300

Æ

20 / 400

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......